Modbus is a serial communication protocol invented by Modicon for the communication between its PLC and the host. Its physical layer adopts asynchronous serial standards such as RS232 and 485. Due to its openness, it is widely adopted by PLC and RTU manufacturers. The Modbus communication method adopts a master-slave query corresponding mechanism. Only when the master station sends a query, the slave station can provide a response, and the slave station cannot actively send data. The master station can send queries to a certain slave station or broadcast information to all slave stations. The slave station only responds to queries sent to it separately, and does not respond to broadcast messages. There are two transmission methods for MODBUS communication protocol: RTU mode and ASCII mode. The Mitsubishi 700 series frequency converter can use the ModbusRTU communication protocol from the RS-485 terminal for communication operation and parameter settings.

Object:

- Mitsubishi PLC: FX2N+FX2N-485-BD

- Mitsubishi frequency converter: F700 series, A700 series.

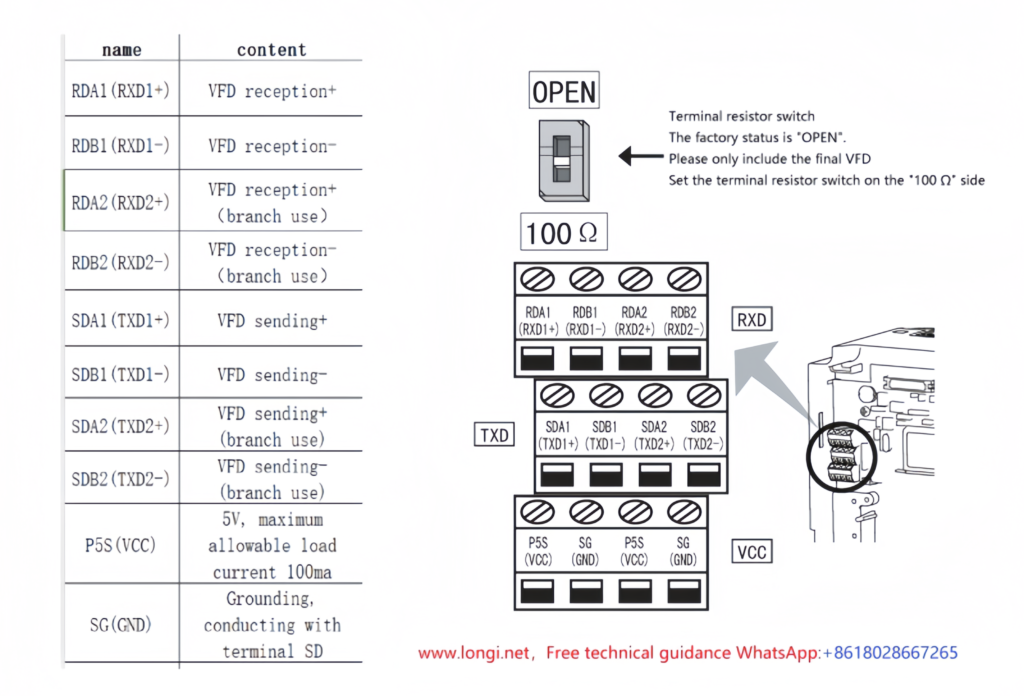

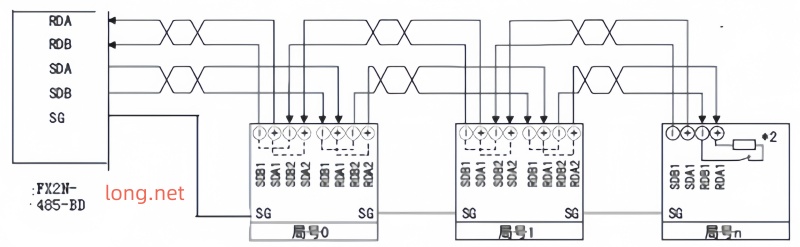

The two are connected through Ethernet cables, as shown in the following figure.

Connection diagram between FX2N-485-BD and n VFDs

1、 Setting up Mitsubishi frequency converters

When communicating between PLC and frequency converter, the communication specifications must be set in the frequency converter. After each parameter initialization setting, the frequency converter needs to be reset or the power supply of the frequency converter needs to be turned on and off.

Parameter Number Name Setting Value Description

Pr331 communication station number 1 sets the frequency converter station number to 1

Pr332 communication speed 96, set communication speed to 9600bps

Pr334 parity check stop bit length 2 even check, stop bit length 1 bit

Pr539 communication verification time 9999 does not perform communication verification

Pr549 protocol selection 1 ModbusRTU protocol

Pr551 PU mode operation right selection 2 PU operation mode operation right as PU interface

When communicating with ModbusRTU protocol, Pr551 must be set to 2, Pr340 is set to a value other than 0, Set Pr79 to 0, 2, or 6. When using the RS-485 terminal for ModbusRTU protocol communication, it must be running in NET network mode.

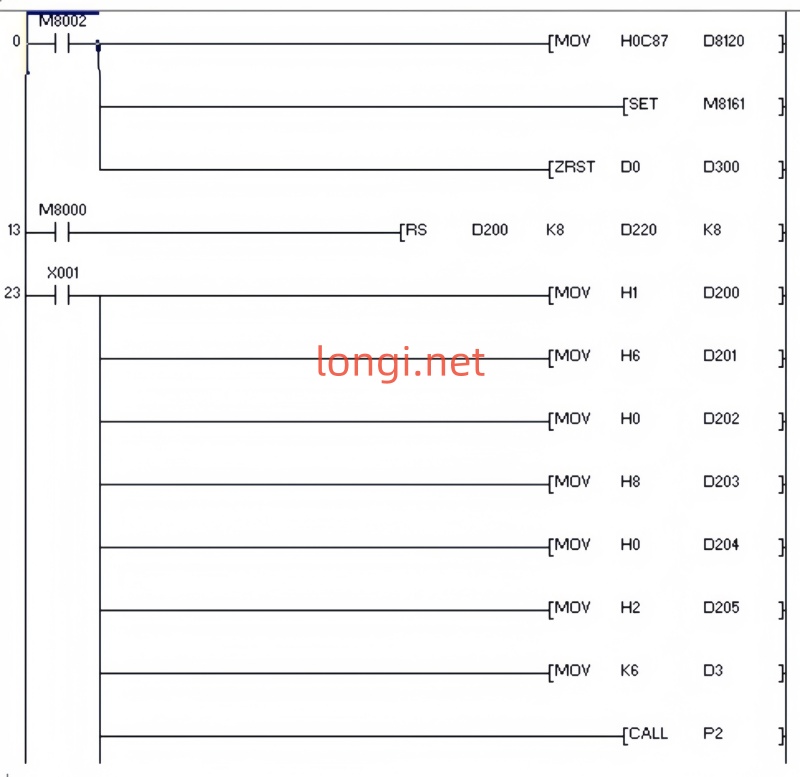

2、 Settings of Mitsubishi PLC

Set communication format D8120

The setting value of D8120 is 0C87, which means the data length is 8 bits, the parity stop bit is 1 bit, the baud rate is 9600pbs, and there is no header or terminator.

After modifying the D8120 settings, ensure that the PLC power is turned on and off once.

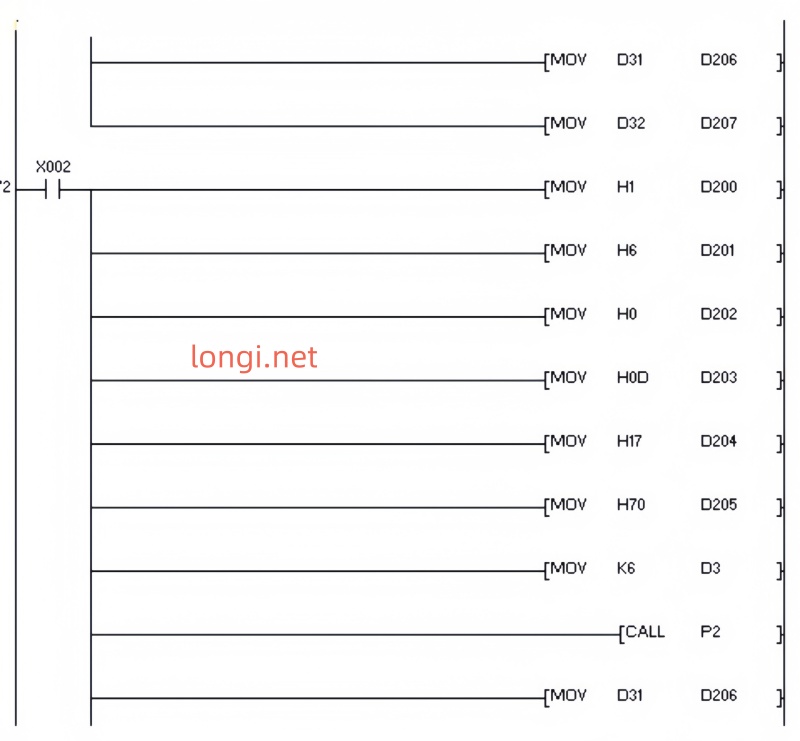

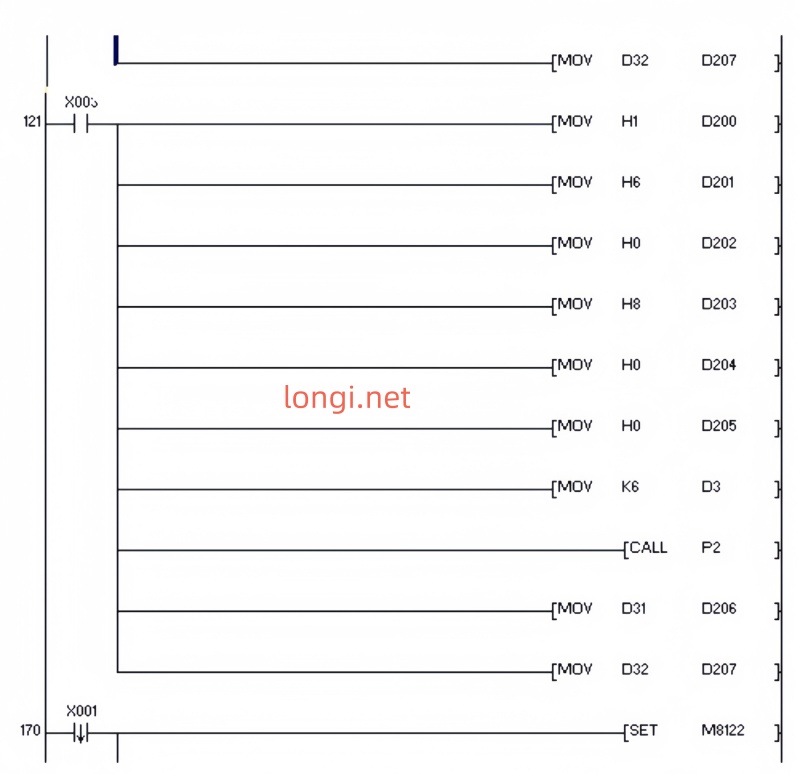

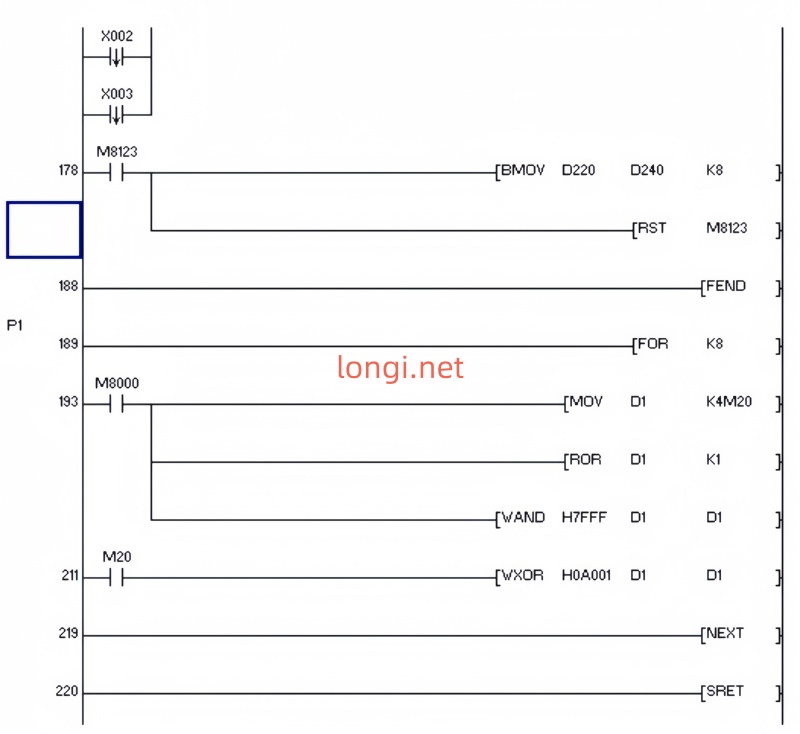

3、 Communication program

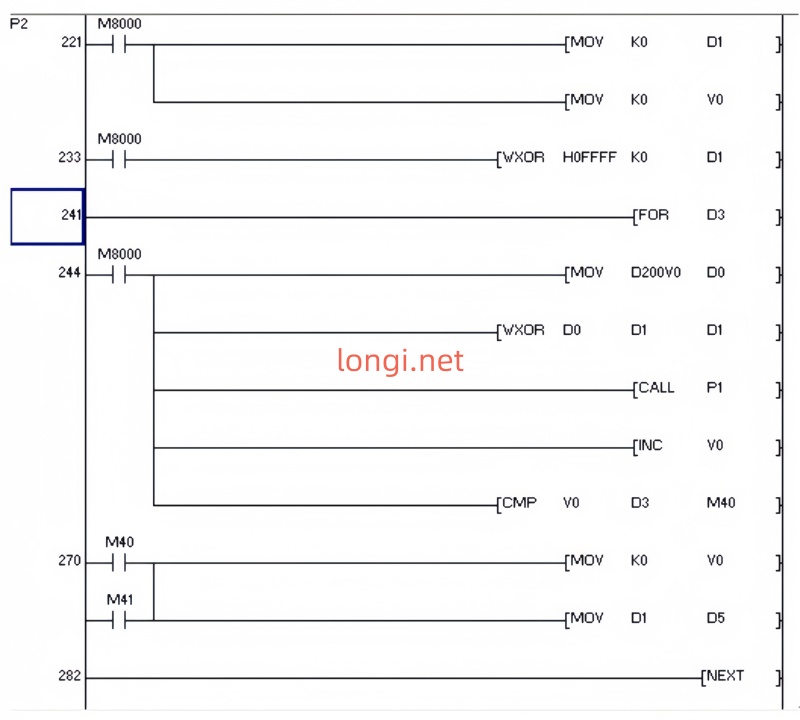

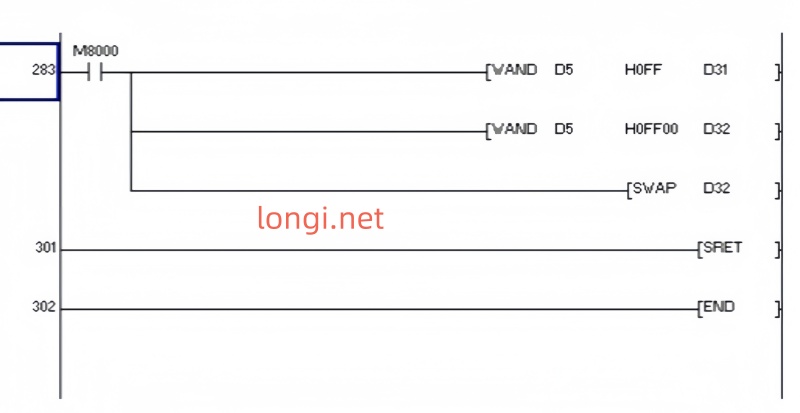

The partial PLC program that uses ModbusRTU protocol to communicate with the frequency converter is as follows: