I. Introduction to Chromatography Instruments

Chromatography instruments separate and analyze mixtures based on the physicochemical properties of their components. Common types include Gas Chromatographs (GC), Online Gas Chromatographs, Liquid Chromatographs (HPLC/UPLC), Ion Chromatographs, PE Atomic Absorption Spectrometers, and Zeeman Effect Atomic Absorption Spectrometers. The core principle involves the distribution or adsorption equilibrium of substances between the stationary and mobile phases to achieve separation. After vaporization in the vaporization chamber, the sample is carried into the column by an inert gas (carrier gas, such as N2, He, etc.). Due to differences in boiling point, polarity, or adsorption properties, components in the sample exhibit different distribution or adsorption behaviors in the column, leading to varying elution times and thus separation. The separated components enter the detector, which converts the presence of sample components into electrical signals proportional to the quantity or concentration of the measured components.

II. Usage Instructions

Startup Preparation:

- Turn on the gas generator and observe if the pressure gauges for air, hydrogen, and nitrogen reach the specified positions.

- Turn on the chromatograph power switch and adjust the temperatures of the injector, column, and detector.

Ignition and Sample Injection:

- When the temperatures reach the set values, ignite the detector flame and adjust the hydrogen flow rate.

- After the signal stabilizes, quickly inject the sample from the sampling cylinder into the chromatograph using a syringe, and record the peak shape and test data.

Data Processing:

- Repeat measurements multiple times and calculate the average to improve accuracy.

- After the test, extinguish the flame, turn off the injector and detector, and wait for the column temperature to drop to room temperature before turning off the chromatograph power.

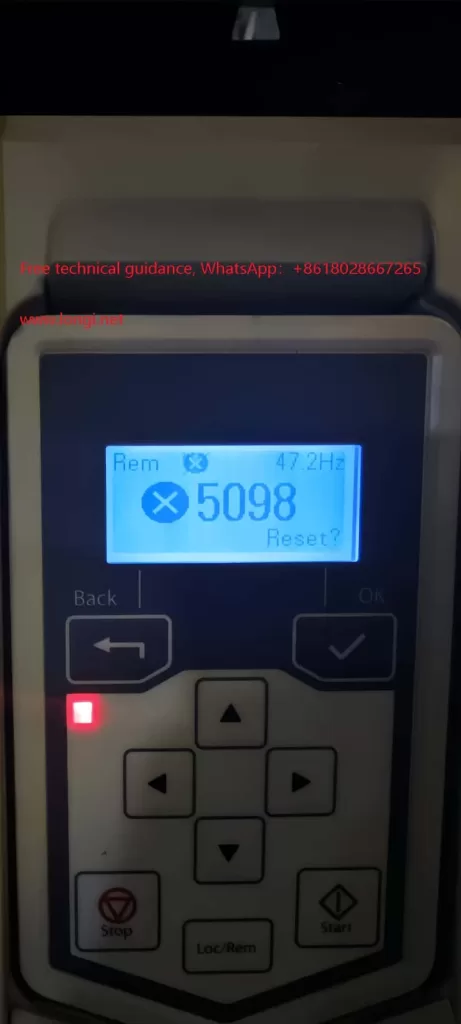

III. Common Faults and Troubleshooting

Injector Faults:

- Blockage: Reinstall the injector plunger and clean with a suitable solvent.

- Leakage: Check and replace the injector seal if aged.

- Improper Installation: Ensure the injection needle is correctly installed on the injector plunger.

Column Faults:

- Blockage: Disconnect the column from the detector end, check for bubbles, and attempt reverse flushing or replacement.

- Contamination: Cut off the contaminated part of the column and re-age or clean it.

- Reduced Efficiency: Replace the column or perform aging treatment.

Detector Faults:

- Abnormal Signal: Check and clean the detector nozzle and gas pipeline regularly.

- Decreased Sensitivity: Adjust detector sensitivity settings and check gas flow rates.

- Contamination: Use high-temperature aging or solvent cleaning for the detector.

System Leaks:

- Check instrument connections, seals, or pipelines for tightness and replace damaged parts.

- Use leak detection solution to check connection points for leaks and ensure instrument sealing.

Background Noise and Baseline Drift:

- Check for a stable instrument environment and adjust detector sensitivity and baseline.

- Regularly calibrate the instrument and check the stability of flow rate, temperature, and pressure parameters.

Flow Rate Issues:

- Check the injection system, flow controller, and column for stable flow.

- Replace the gas flow control valve or adjust gas flow settings.

Sample Contamination:

- Prepare clean samples and regularly clean the injector and system.

- Use pre-columns or guard columns to capture semi-volatile and non-volatile impurities.

IV. Maintenance Precautions

- Before any maintenance, always turn off the chromatograph power and disconnect from the power source.

- Use appropriate tools and solvents for cleaning and maintenance to avoid damaging instrument components.

- Regularly maintain and service the instrument, such as replacing filters and cleaning nozzles and gas pipelines.

- For complex faults, consult the instrument operation manual or seek assistance from professional technicians.

V. Brands and Models Repaired by Rongji Electromechanical Company

Agilent Technologies:

- GC: 8890 GC System, 7890B GC System, 8860 GC System

- HPLC/UPLC: 1290 Infinity II LC System, 1260 Infinity II LC System, 1220 Infinity II LC System

- GC-MS: 8890 GC/MSD System, 7250 GC/Q-TOF, 7010 Triple Quadrupole GC/MS

- LC-MS: 6546 LC/Q-TOF, 6470 LC/TQ, 6495B LC/TQ

Thermo Fisher Scientific:

- GC: TRACE 1310 GC, TRACE 1300 GC

- HPLC/UPLC: Vanquish UHPLC System, UltiMate 3000 HPLC System

- GC-MS: TSQ 9000 GC-MS/MS, ISQ 7000 Single Quadrupole GC-MS

- LC-MS: Orbitrap Exploris 240, TSQ Altis Triple Quadrupole, Q Exactive HF-X

Shimadzu:

- GC: Nexis GC-2030, GC-2010 Plus

- HPLC/UPLC: Nexera X2 UHPLC, Prominence HPLC

- GC-MS: GCMS-QP2020 NX, GCMS-TQ8050 NX

- LC-MS: LCMS-8050, LCMS-8060

Waters:

- HPLC/UPLC: ACQUITY UPLC H-Class PLUS, ACQUITY Arc System, Alliance HPLC System

- LC-MS: Xevo TQ-S micro, Xevo G2-XS QTof, SYNAPT XS

PerkinElmer:

- GC: Clarus 690 GC, Clarus 580 GC

- HPLC/UPLC: Flexar UHPLC, Flexar HPLC, LC-2030C

- GC-MS: Clarus SQ 8 GC/MS

- LC-MS: QSight 220 Triple Quad

Bruker:

- GC-MS: SCION TQ, SCION SQ

- LC-MS: timsTOF Pro, maXis II

SCIEX:

- LC-MS: TripleTOF 6600, Triple Quad 7500, X500R QTOF

Hitachi High-Tech:

- HPLC/UPLC: Chromaster HPLC, LaChromUltra

JASCO:

- HPLC/UPLC: LC-4000 Series, X-LC Series

LECO:

- GC: Pegasus BT GC-TOFMS, Pegasus 4D GCxGC-TOFMS

Tianmei (Selian):

- GC: SCION 8300 GC, SCION 8500, Selian 436i/456i, GC7980, GC7980Plus, GC7900

Varian (acquired by Agilent):

- GC: CP-3800, CP-3900, Varian 450-GC, Varian 490-GC

- HPLC: Varian ProStar 210 HPLC, Varian ProStar 218 HPLC, Varian ProStar 335 HPLC, Varian 940-LC

- GC-MS: Varian Saturn 2000 GC/MS, Varian Saturn 2200 GC/MS, Varian 450-GC/320-MS, Varian 431-GC/210-MS

- LC-MS: Varian 1200-LC, Varian 500-MS LC/MS, Varian 610-MS LC/MS

- IC: Varian 920-LC

About Rongji Electromechanical Company

With nearly 30 years of experience in repairing chromatography instruments, Rongji Electromechanical Company offers swift and efficient repairs for various types of chromatographs. Additionally, we recycle and sell used chromatographs. For more information, please contact us.