The ACS580 stands as an upgraded iteration compared to the previous ABB ACS550 inverter, boasting enhanced functionalities like vector control. Its versatile applications cover a wide range. Internally, the ACS580 exhibits a distinct circuit structure from its predecessor, the ACS550. In the course of ACS580 usage, encountering various faults and alarm scenarios is common. However, the fault codes and alarms differ significantly from those of the ACS550, necessitating reference to the ACS580 firmware manual for troubleshooting.

In practical scenarios, some fault codes encountered with the ACS580 may not be documented in the manual, presenting a unique challenge. This situation often leaves many electrical engineers puzzled. For instance, a typical fault code such as “7122” cannot be located in any of the ACS580 manuals. Below, you’ll find a table detailing fault codes for the ACS580.

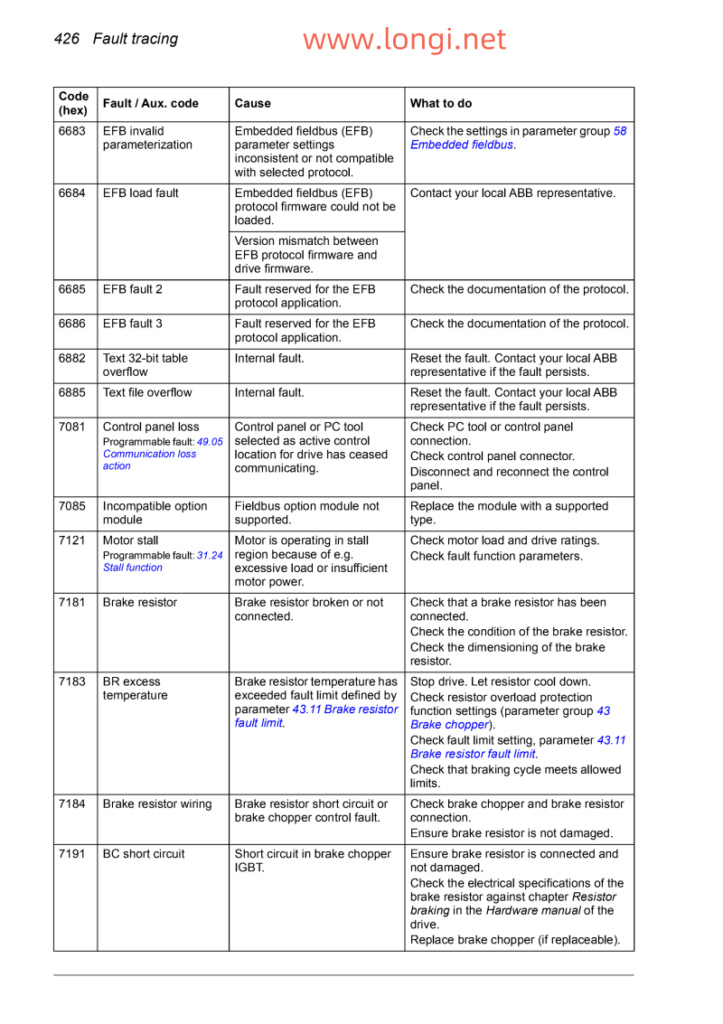

In the provided table, we notice adjacent fault codes like 7121 and 7181, yet codes like 7122, 7123, 7124, and so forth are conspicuously absent. When faced with such a scenario, how does one determine the meaning of abb acs580 fault code 7122?

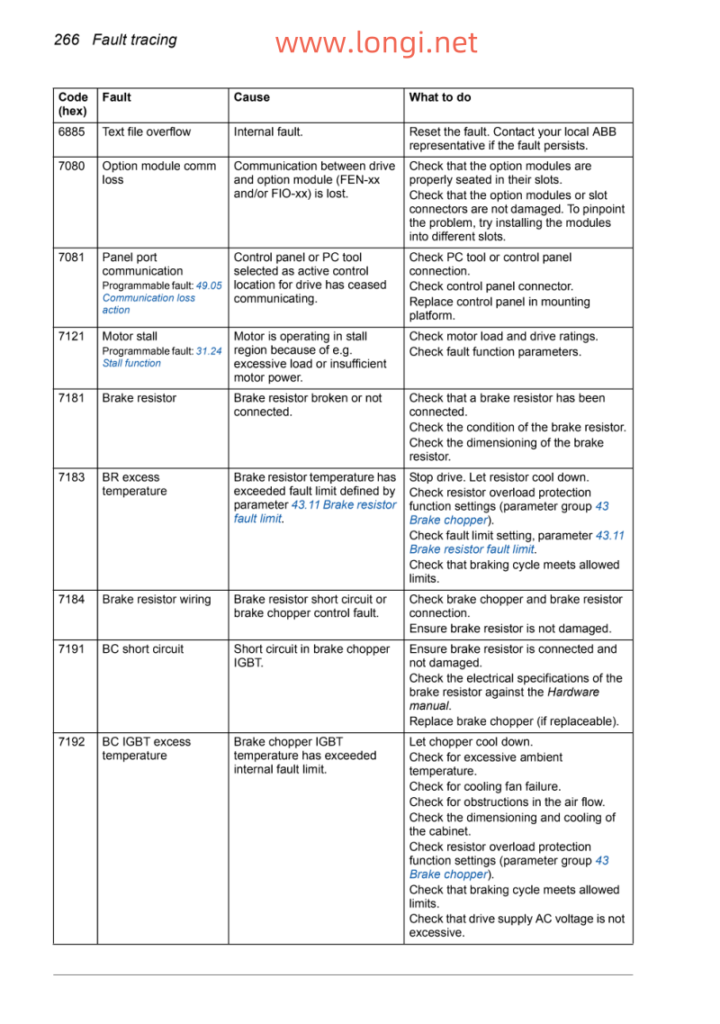

Those familiar with the internal hardware structure of the ACS580 inverter understand that the high-power mainboard of the ACS580 closely resembles that of the ACS880. In pursuit of clarity, we consulted the firmware manual for the ACS880 and searched its fault code table, only to find no mention of code 7122, as displayed below:

It’s evident that although there are some differences in the fault code listings between the ACS580 and ACS880, the explanations for the fault alarm content are nearly identical as long as the codes match. This demonstrates that many fault code contents in ABB inverters can be cross-referenced within a series. However, it’s regrettable that even in the ACS880’s code table, an explanation for “7122” cannot be found.

Finding ourselves in a predicament, with neither inverter providing an explanation for fault code “7122,” what can we do next?

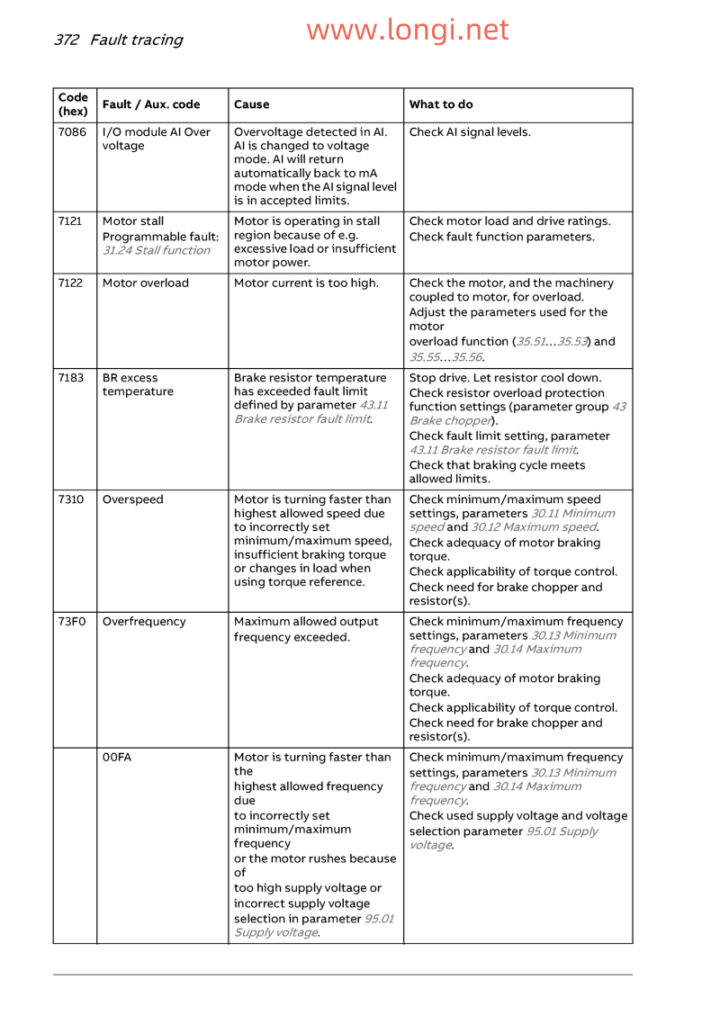

Upon further exploration, we recall that ABB also offers a compact low-power inverter called the ACS150, which shares hardware and software structures similar to the ACS550. Considering this, the upgraded version of the ACS150 should be the ACS180. We swiftly locate the firmware manual for the ACS180 and navigate to the vicinity of the fault code table. To our amazement, a miracle unfolds, as depicted in the table below:

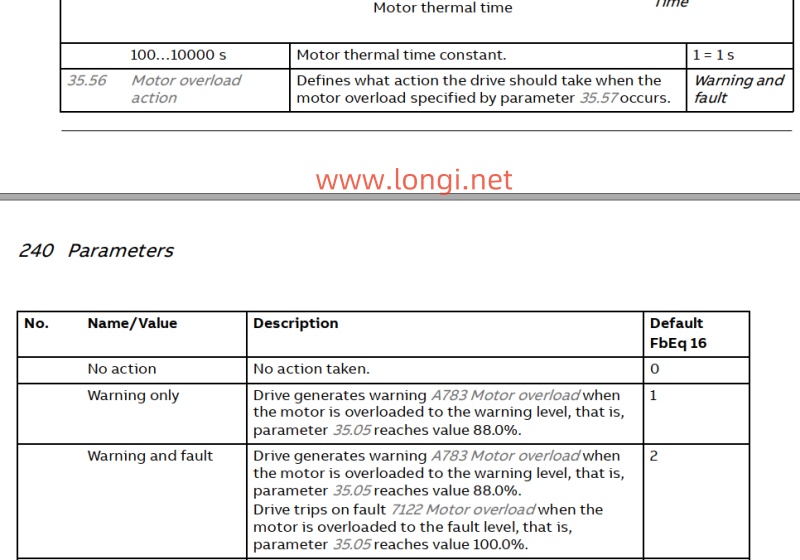

The table clearly indicates that “7122” is an overload alarm, further specifying that it’s caused by excessively high motor current. Besides verifying if the motor is genuinely overloaded, it’s also necessary to inspect parameters 35.51, 35.52, 35.53, 35.55, and 35.56. Upon comparing these parameters in the ACS580 firmware manual, astonishingly, they closely resemble those in the ACS180. Parameter 35.51 defaults to 110%, but in such cases, it can be adjusted higher, say 150%. However, this adjustment necessitates ensuring that the motor hardware is in good condition and the motor power meets the on-site load requirements.

Further investigation reveals that the ACS180 inverter does include parameter 35.56, whereas the ACS580 does not offer this parameter as an option. Interestingly, setting parameter 35.56 to 0 can effectively disable motor overload alarms, effectively masking fault code 7122.

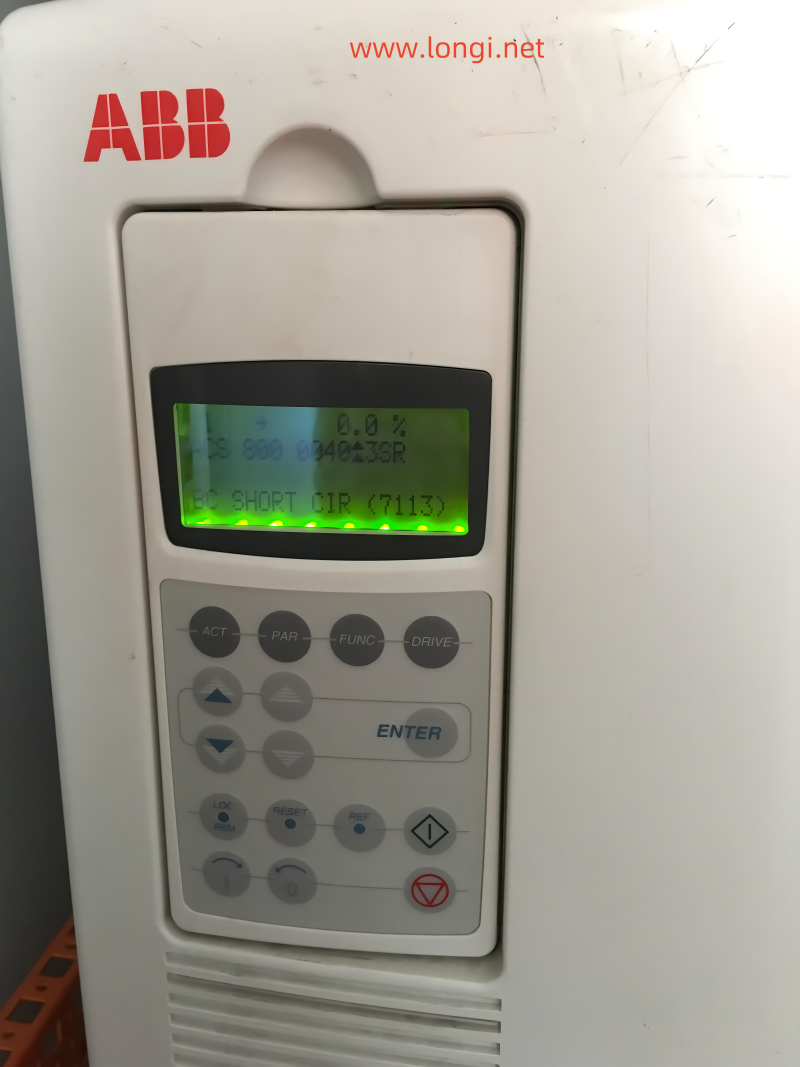

This indicates that the hardware and software of ABB’s drives—ACS180, ACS580, and ACS880—are essentially the same. Perhaps their underlying programs are identical, and they merely display different series and functionalities through specific settings. Fault code 7122 and the hardware detection function are present in each inverter model, but in the ACS580 and ACS880, the hardware circuitry suppresses it. However, if there’s an issue with the hardware circuitry, such as poor contact or breakage in the connection between the mainboard and the drive board, it may trigger fault code 7122 directly, with no apparent means of suppression, and the fault alarm details may not be found in the inverter’s manual.

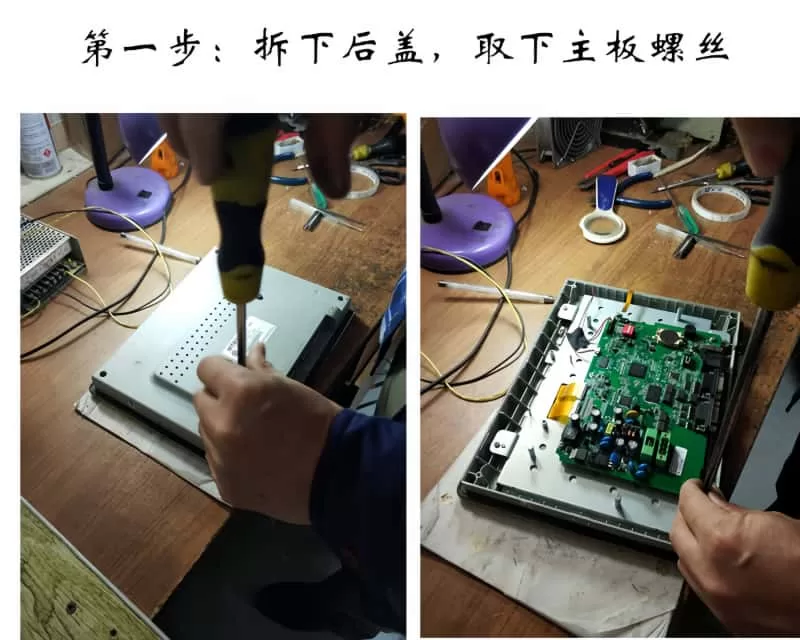

Conclusion: When fault codes like 7122 appear on ACS580 or ACS880 inverters, it’s usually indicative of an internal hardware circuit problem. In such cases, removing the inverter, checking the connections and plugs, and clearing dust may resolve the issue. If this doesn’t suffice, it’s likely that a component on the board is faulty, requiring the inverter to be repaired.