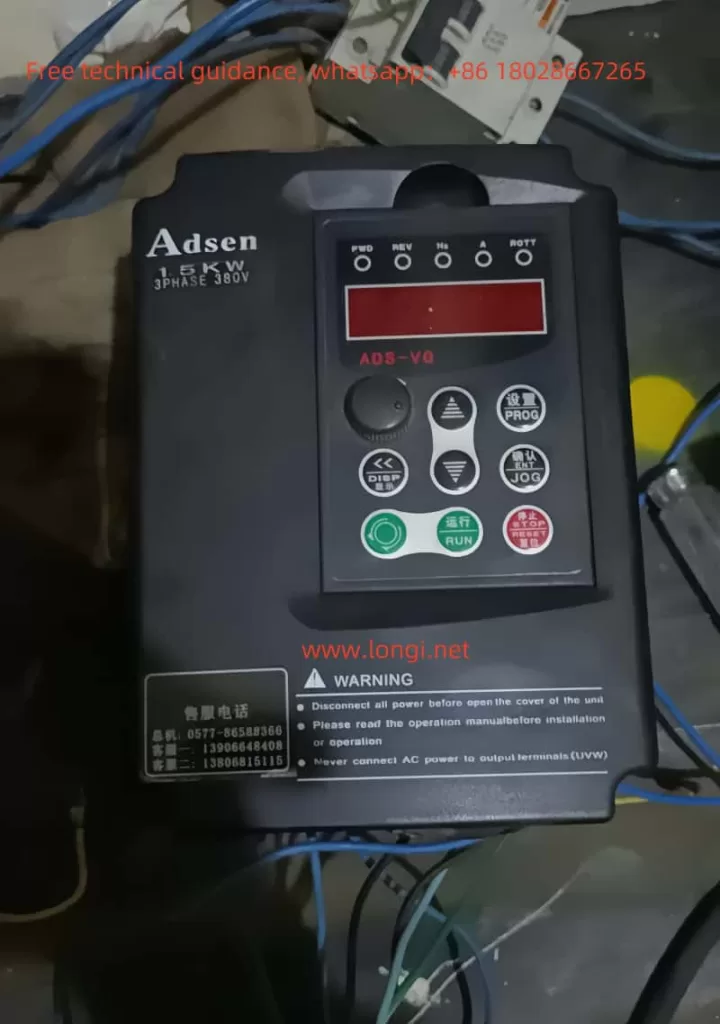

I. Introduction to Operation Panel Functions

The operation panel of the ADSEN Variable Frequency Drive (VFD) ADS-V series serves as a crucial interface for user interaction with the device. The panel typically includes multiple function keys and a display screen, allowing users to perform operations such as start, stop, frequency setting, and parameter modification. The main function keys on the panel include:

- Run Key: Starts the VFD operation.

- Stop/Reset Key: Stops the VFD operation or resets it after a fault occurs.

- Forward/Reverse Switch Key: Switches the running direction of the VFD.

- Set Key: Enters the parameter setting mode.

- Display/Shift Key: Cycles through different parameters such as output frequency, current, temperature, etc., in display mode.

1.1 Initializing Parameters (Restoring Factory Settings)

To restore all parameters of the VFD to factory settings, users can follow these steps:

- Press the “Set” key to display “Pr000”.

- Use the “Increase” or “Decrease” key to adjust to “Pr013” (parameter reset) and set the value to “01”.

- Press the “Confirm” key (usually the “Jog” key) to confirm the reset.

- At this point, the VFD will restore to factory settings, and all user-set parameters will be cleared.

1.2 Setting and Removing a Password

To protect the parameter security of the VFD, users can set a password to prevent unauthorized access. The specific steps are as follows:

- Enter the parameter setting mode and locate “Pr000” (parameter lock).

- Set the value to “1” to enable password protection.

- To remove the password, set it to “0”.

1.3 Setting Parameter Access Restrictions

After setting the parameter lock in “Pr000”, users can prevent others from modifying the parameters. A setting of “0” indicates invalid, while “1” indicates valid. Users must unlock before modifying parameters.

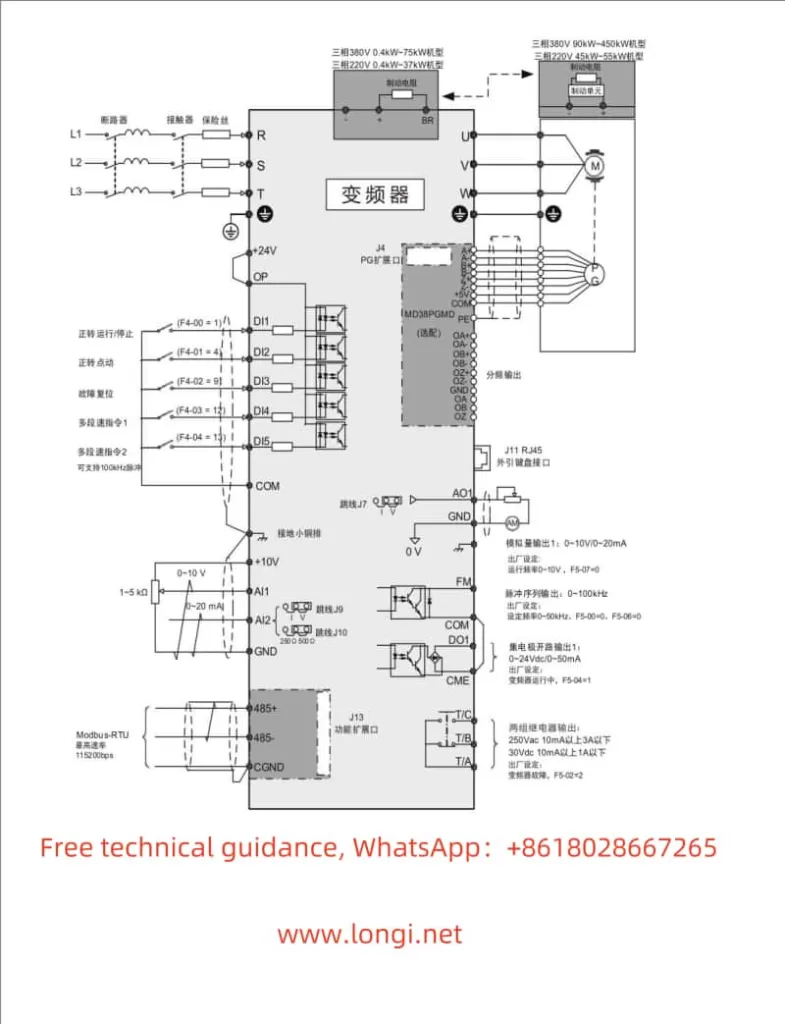

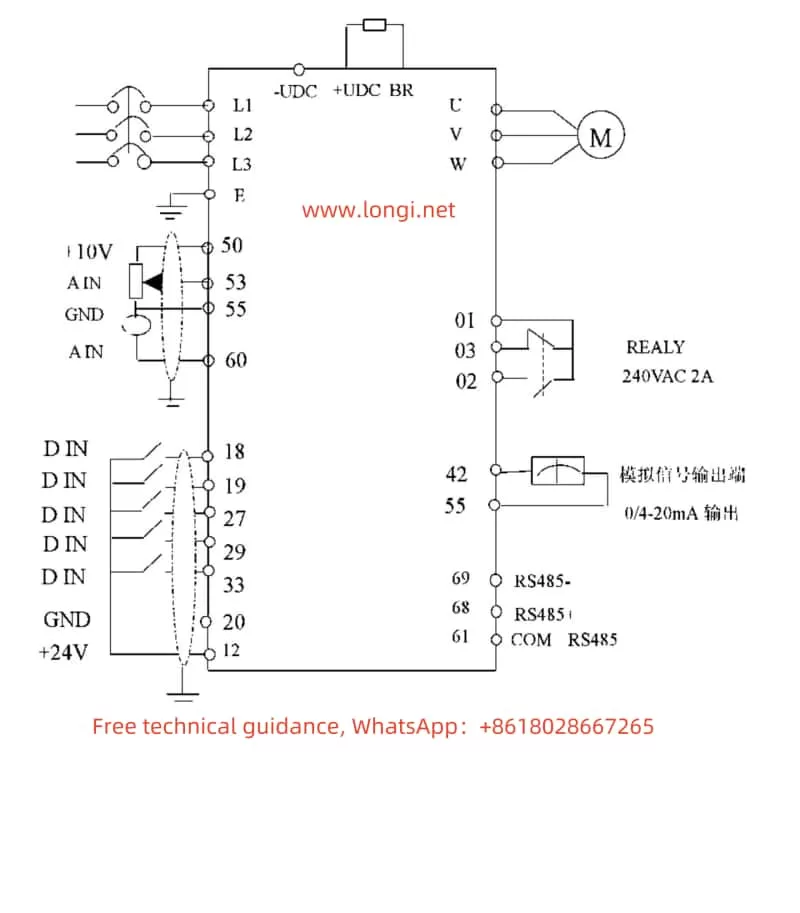

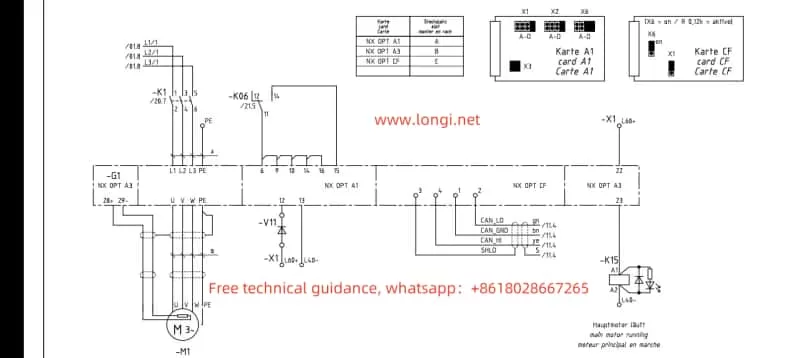

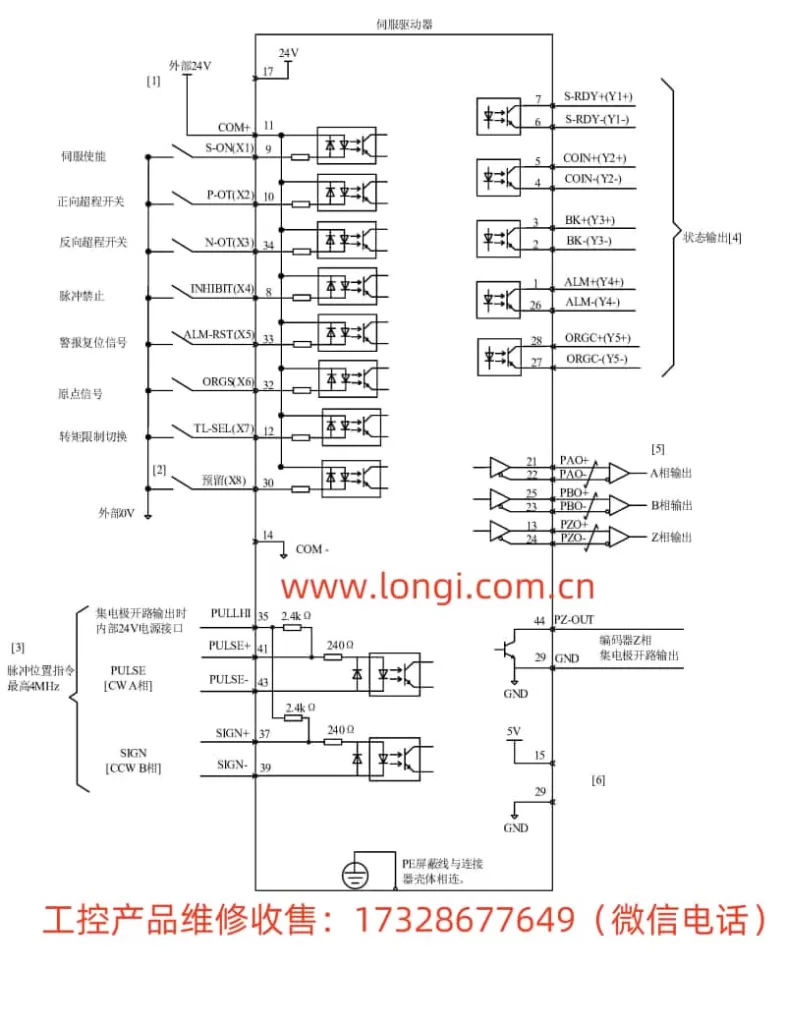

II. External Terminal Forward/Reverse Control and External Potentiometer Frequency Speed Adjustment

2.1 External Terminal Forward/Reverse Control

To achieve external terminal forward/reverse control, users need to wire the following terminals:

- X1 Terminal: Run control signal.

- X2 Terminal: Reverse control signal.

- X3 Terminal: Stop control signal.

Parameter Settings:

- Set “Pr001” to “1” to select external terminal control.

- Set “Pr044” to “02” to assign X1 as run.

- Set “Pr045” to “03” to assign X2 as reverse.

- X3 terminal can be set as stop.

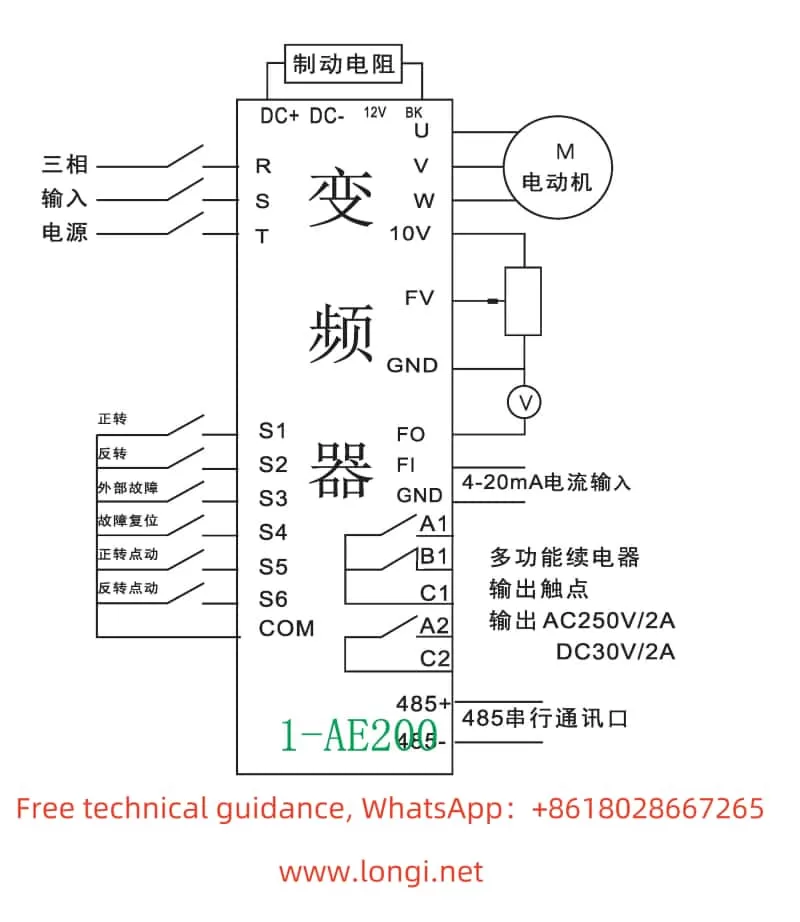

2.2 External Potentiometer Frequency Speed Adjustment

Connect the external potentiometer to the following terminals:

- FV Terminal: Frequency setting input.

- GND Terminal: Ground.

Parameter Settings:

- Set “Pr001” to “1” to select external terminal control.

- Set “Pr002” to “1” to select external potentiometer for frequency setting.

- Set “Pr072” to the desired maximum frequency (e.g., 50Hz).

With these settings, users can adjust the output frequency of the VFD using an external potentiometer.

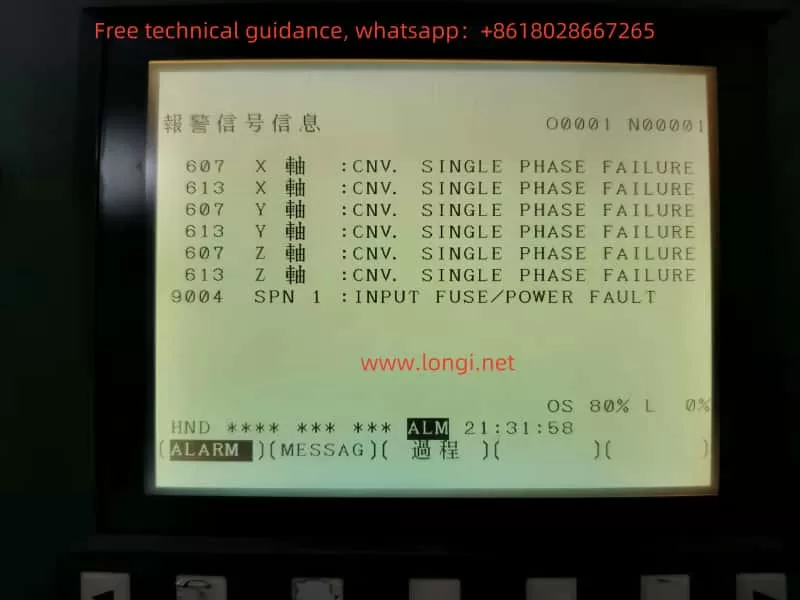

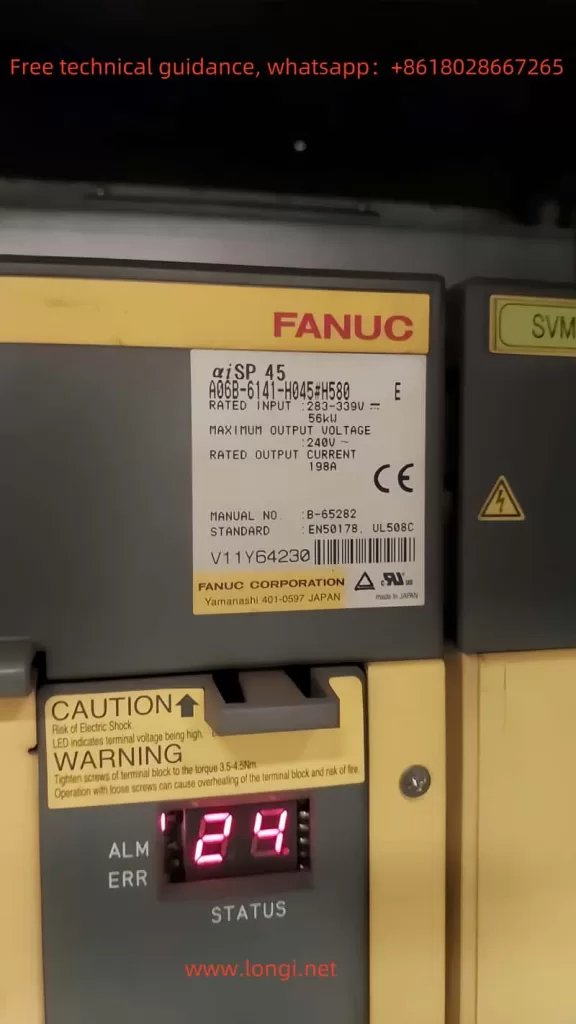

III. Fault Codes and Troubleshooting

The ADSEN VFD ADS-V series provides multiple fault protection functions. Common fault codes and their troubleshooting methods are as follows:

3.1 Common Fault Codes

- OU-1: Overvoltage during acceleration

- Troubleshooting: Check the grid voltage and extend the acceleration/deceleration time.

- OU-2: Overvoltage during deceleration

- Troubleshooting: Extend the deceleration time or install a braking resistor.

- FB: Fuse blown

- Troubleshooting: Send for factory repair.

- OH: VFD overheat

- Troubleshooting: Check if the fan is blocked and ensure the ambient temperature is normal.

- OL-1: VFD overcurrent or overload

- Troubleshooting: Check if the load is too large and reset the parameters.

- LV: Undervoltage

- Troubleshooting: Check if the input voltage is normal.

3.2 Fault Handling

In the event of a fault, immediately press the stop key and record the fault code. Users should refer to the manual for corresponding checks and troubleshooting based on the fault code. If the fault cannot be resolved, contact professional technicians for repair.

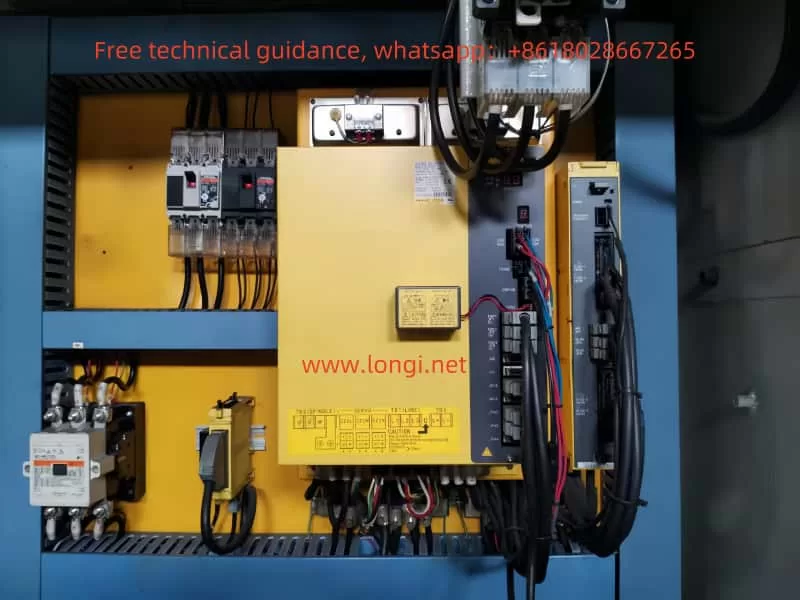

IV. Summary

The user manual of the ADSEN VFD ADS-V series provides a detailed operation guide. Users should be familiar with the functions of the operation panel and fault troubleshooting methods during daily operations. By properly setting parameters and conducting effective maintenance checks, the normal operation of the VFD can be ensured, and its service life can be extended. In practical applications, if any issues are encountered, users should refer to the manual for resolution or contact professionals for support.