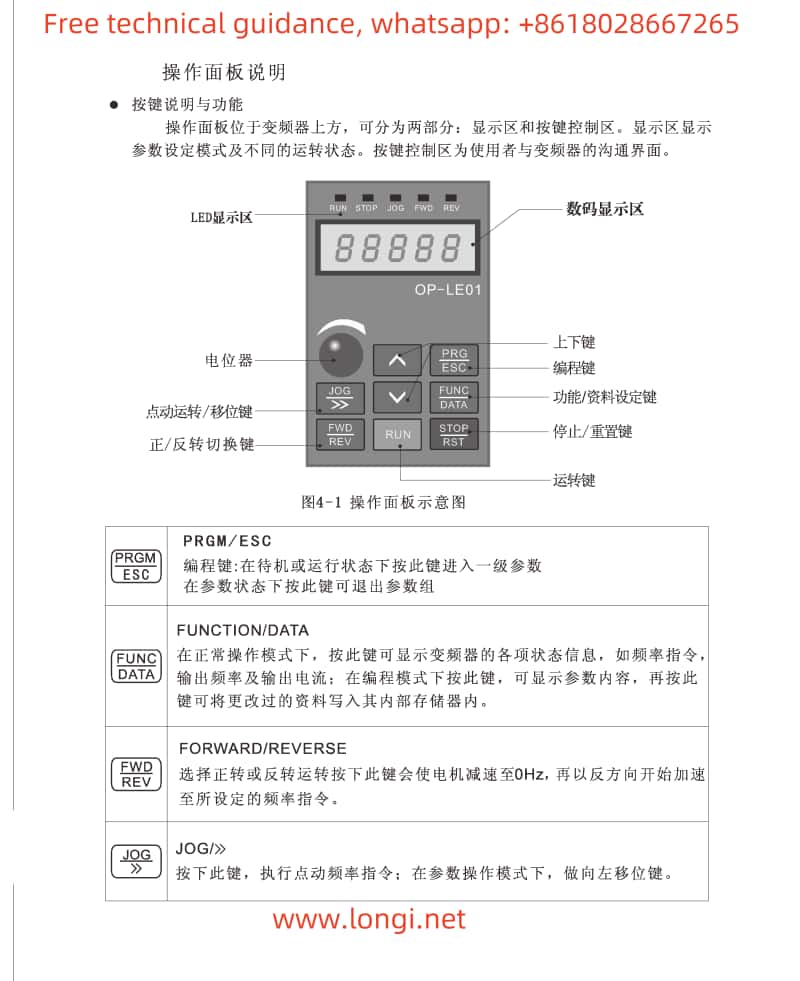

Operation Panel Key Descriptions:

- PRGM/ESC: Program setting and exit key. PRGM is used to enter programming mode or set parameters, while ESC is used to exit the current setting or return to the previous menu.

- FUNCTION/DATA: Function selection and data key. FUNCTION is used to enter the function selection interface, and DATA is used to modify data values during parameter setting.

- FORWARD/REVERSE: Forward and reverse control key. Controls the forward or reverse rotation of the motor.

- JOG/>>: Jog and page turning key. JOG is used for jog control, and >> may be used for page turning or increasing parameter values (specific functions may vary depending on the model).

- RUN: Run key. Controls the startup of the VFD.

- STOP/RST: Stop and reset key. STOP is used to stop the VFD operation, and RST is used to reset the VFD and clear fault states.

- UP/DOWN: Up and down adjustment key. Used to increase or decrease values during parameter setting.

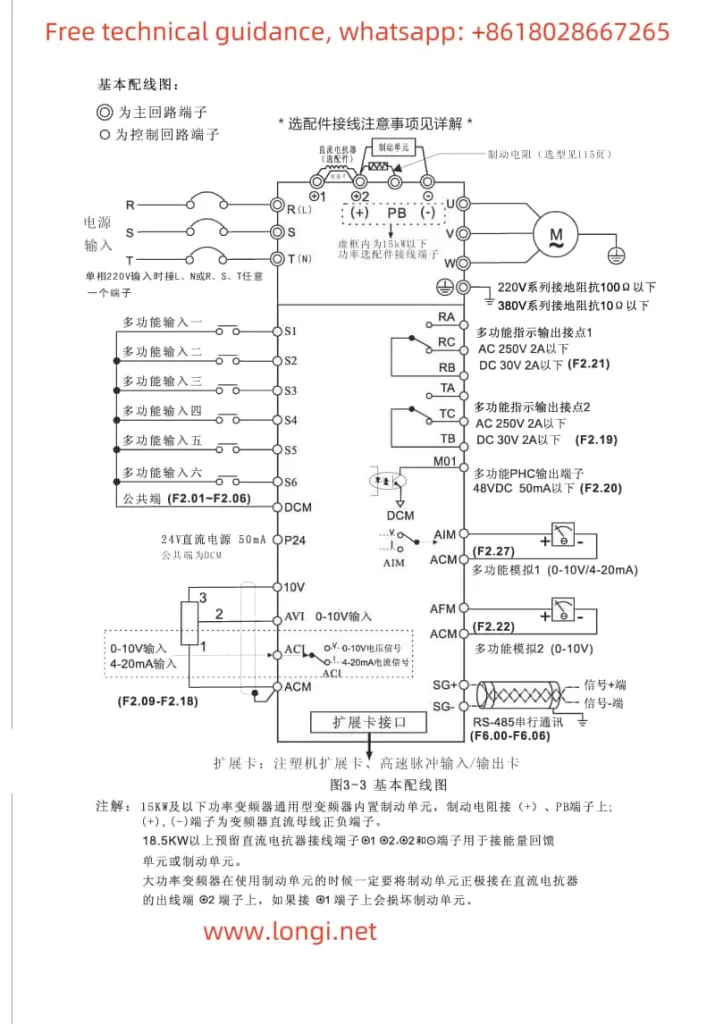

Terminal Start/Stop and Potentiometer Debugging Wiring Instructions:

Terminal Start/Stop:

- Parameter Setting: Ensure parameter F0.02 is set to 1, selecting terminal control mode.

- Wiring Instructions:

- Connect the external start signal to the S1 terminal of the VFD.

- Short-circuit the S1 terminal with the common terminal DCM to send a start signal, causing the VFD to begin operation.

- Disconnect the short-circuit between S1 and DCM to send a stop signal, causing the VFD to stop operation.

Potentiometer Debugging:

- Parameter Setting: Ensure parameter F0.03 is set to 1, selecting external potentiometer speed adjustment mode.

- Wiring Instructions:

- Connect the center tap (sliding contact) of the potentiometer to the AVI terminal of the VFD.

- Connect the two ends of the potentiometer to the 10V (or similar positive power supply) and ACM (or similar common terminal) of the VFD, respectively.

- Adjust the position of the potentiometer to change the voltage value of the AVI terminal, thereby controlling the output frequency of the VFD.

Fault Code Analysis and Solutions:

Fault Codes:

- E001: DC bus fault. Possible causes include abnormal input power, faulty bus capacitors, etc. Solution: Check if the power input is normal, inspect the bus capacitors for damage, and replace if necessary.

- E002: Acceleration overvoltage. Possible causes include excessively short acceleration time, sudden load changes, etc. Solution: Adjust the acceleration time and check for load stability.

- E003: Constant speed overvoltage. Similar to E002 but occurs during constant speed operation. Solution is the same.

- E004: Acceleration overcurrent. Possible causes include motor stall, excessive load, etc. Solution: Inspect the motor and load conditions, reduce the load, or optimize motor operating conditions.

- E005: Deceleration overcurrent. Possible causes include excessively short deceleration time, large load inertia, etc. Solution: Adjust the deceleration time and consider using a braking unit and braking resistor.

Please note that the above content is based on the information you provided. During actual operation, please refer to the VFD manual and related materials. If you have any questions, please contact Longi Electromechanical’s technical support or professional maintenance personnel promptly.