I. Introduction to the Operation Panel Functions and Parameter Settings

1.1 Operation Panel Functions

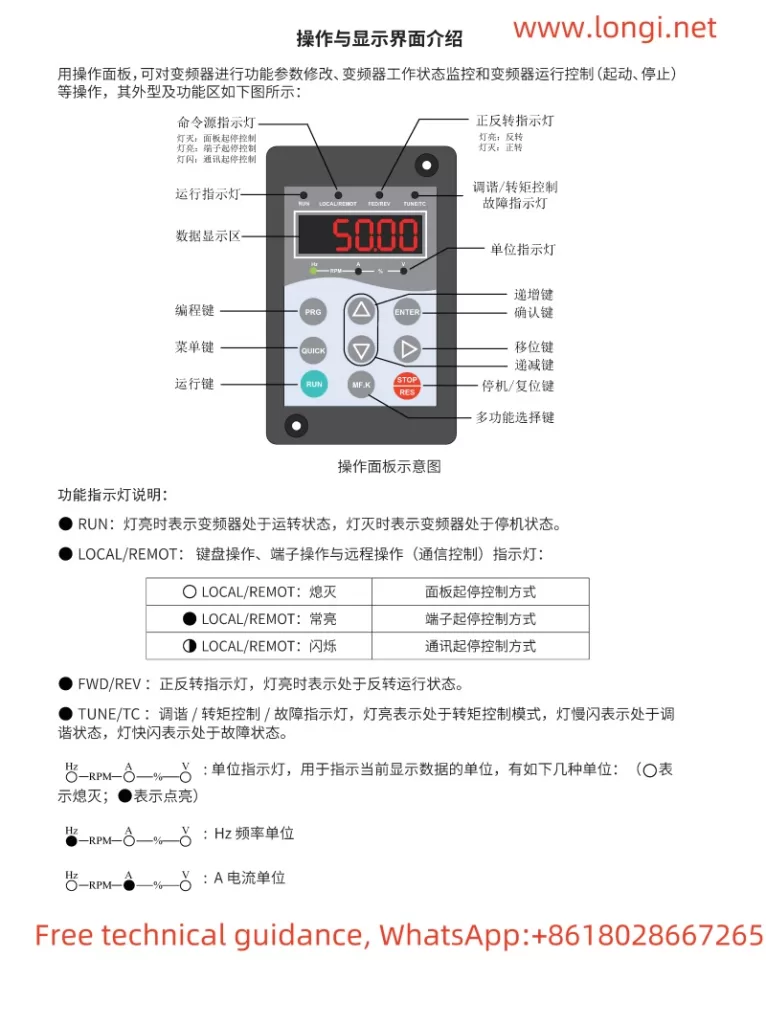

The operation panel of the Inovance MD380 series inverter is a crucial tool for users to set parameters, monitor status, and diagnose faults. The operation panel primarily consists of an LED display, function keys, and multiple input/output ports. The LED display shows current operating parameters such as frequency, voltage, and current. The function keys include PRG (Program), ENTER (Confirm), RUN (Run), STOP/RESET (Stop/Reset), and MF.K (Multi-Function Key), which users utilize for menu navigation and parameter modification.

1.2 Restoring Factory Defaults

Restoring factory defaults clears user-defined parameters, resetting the inverter to its default settings at the time of manufacture. The steps are as follows:

- Enter the Function Parameter Mode: Press the PRG key to enter the function parameter mode.

- Select the FP Group Function Code: Use the ▲ or ▼ keys to select the FP group function code (FP-01).

- Set to Restore Factory Defaults: Press the ENTER key to enter the FP-01 parameter setting, set the value of FP-01 to 1, and then press ENTER to confirm. The inverter will then automatically restart and restore to its factory default settings.

1.3 Setting and Clearing Passwords

Password protection prevents unauthorized users from modifying inverter parameters. The steps to set and clear passwords are as follows:

- Setting a Password: Set the value of the FP-00 function code to a non-zero number, such as 1234, and then press ENTER to confirm. Password protection is now enabled, and entering the function parameter mode will require a password.

- Clearing the Password: Set the value of the FP-00 function code to 0 and then press ENTER to confirm. This disables password protection, and entering the function parameter mode will no longer require a password.

II. Terminal Start/Stop and External Potentiometer Speed Adjustment Settings

2.1 Wiring Instructions

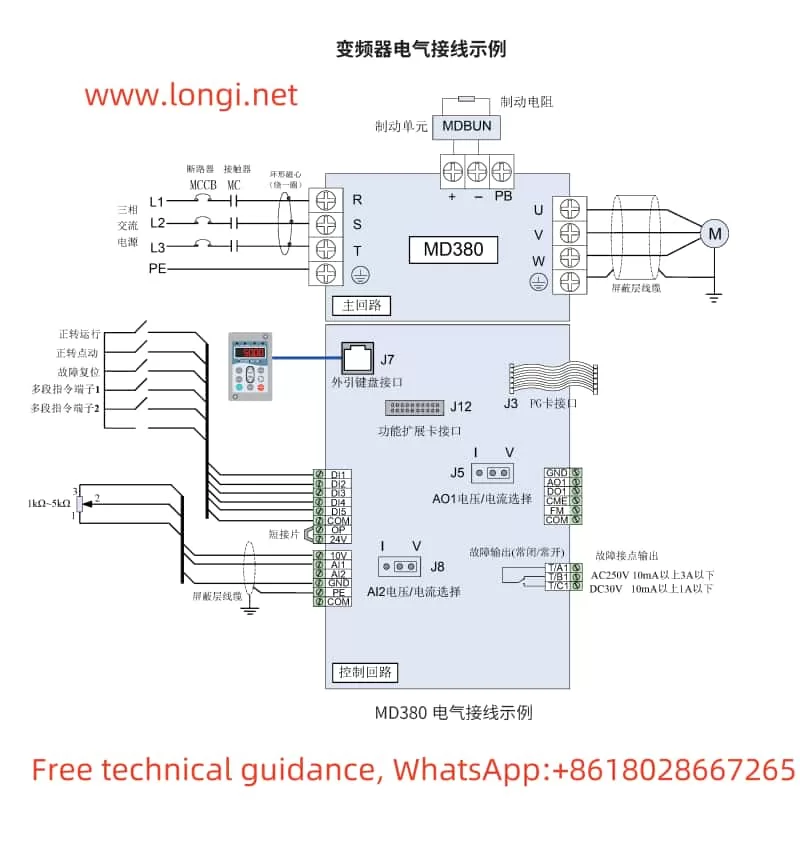

To achieve terminal start/stop and external potentiometer speed adjustment, the control terminals of the inverter must be correctly connected. The specific wiring is as follows:

- Start Terminal (DI1): Connect one end of the external start button to DI1 and the other end to the common terminal (COM).

- Stop Terminal (DI2): Connect one end of the external stop button to DI2 and the other end to the common terminal (COM).

- Speed Adjustment Terminal (AI1): Connect the center tap of the external potentiometer to AI1, and the two ends of the potentiometer to +10V and GND, respectively.

2.2 Parameter Settings

After completing the wiring, the inverter must be configured with specific parameters to achieve the desired functionality. The settings are as follows:

- Set the Command Source: Set the value of the F0-02 function code to 1 to select the terminal command channel.

- Set DI1 and DI2 Functions: Set the value of the F4-00 function code to 1 (forward operation) and the value of the F4-01 function code to 4 (reverse operation) or as required.

- Set AI1 Function: Configure the F4-13 to F4-16 function codes to set the input range and corresponding set values for AI1, ensuring that the output of the external potentiometer matches the frequency setting of the inverter.

- Other Related Settings: Set parameters such as acceleration and deceleration times and frequency limits as needed.

III. Fault Codes and Troubleshooting

3.1 Fault Codes and Their Meanings

The Inovance MD380 series inverter features comprehensive fault self-diagnosis functionality. When a fault occurs, the inverter displays the corresponding fault code. Common fault codes and their meanings are as follows:

- Err01: Overcurrent fault, indicating that the inverter output current exceeds the set value.

- Err02: Overvoltage fault, indicating that the inverter input voltage is too high.

- Err03: Undervoltage fault, indicating that the inverter input voltage is too low.

- Err07: Overload fault, indicating that the inverter output torque exceeds the set value.

- Err11: Motor overload fault, indicating that the motor current is too high.

- Err12: Input phase loss fault, indicating that the inverter input power supply is missing a phase.

- Err15: External fault, indicating that the external fault input terminal is active.

- Err16: Communication abnormality fault, indicating that communication between the inverter and the host computer is abnormal.

3.2 Troubleshooting

Different fault codes require specific troubleshooting steps:

- Overcurrent Fault (Err01): Check if the motor and load are too large, and adjust the acceleration and deceleration times or reduce the output frequency.

- Overvoltage Fault (Err02): Check if the input power supply voltage is too high or install a braking resistor to dissipate excess energy.

- Undervoltage Fault (Err03): Check if the input power supply voltage is too low or if the power supply line connection is poor.

- Overload Fault (Err07): Check if the load is too large and adjust the overload protection parameters.

- Motor Overload Fault (Err11): Check if the motor is stalled or the load is too large, and adjust the motor overload protection parameters.

- Input Phase Loss Fault (Err12): Check if the input power supply is missing a phase or if the power supply line connection is good.

- External Fault (Err15): Check if the external fault input terminal is misconnected or damaged and eliminate the external fault source.

- Communication Abnormality Fault (Err16): Check if the communication line is connected correctly or replace the communication cable.

By following the steps outlined above, users can gain a comprehensive understanding of the operation panel functions, parameter setting methods, terminal start/stop and external potentiometer speed adjustment settings, as well as fault code troubleshooting for the Inovance MD380 series inverter, thereby enabling better use and maintenance of the inverter equipment.