The YQ3000-F11 inverter from Yuqiang, with its high performance and reliable stability, is widely used in various industrial automation applications. This article will provide a detailed introduction to the panel startup and speed adjustment methods, how to restore factory default settings, specific wiring and parameter settings for terminal forward/reverse rotation and external potentiometer speed adjustment, as well as the steps to implement PID function for single-loop closed-loop pressure control on a single-pump constant pressure water supply system. Additionally, fault code meanings and solutions will be provided.

I. Panel Startup and Speed Adjustment Methods

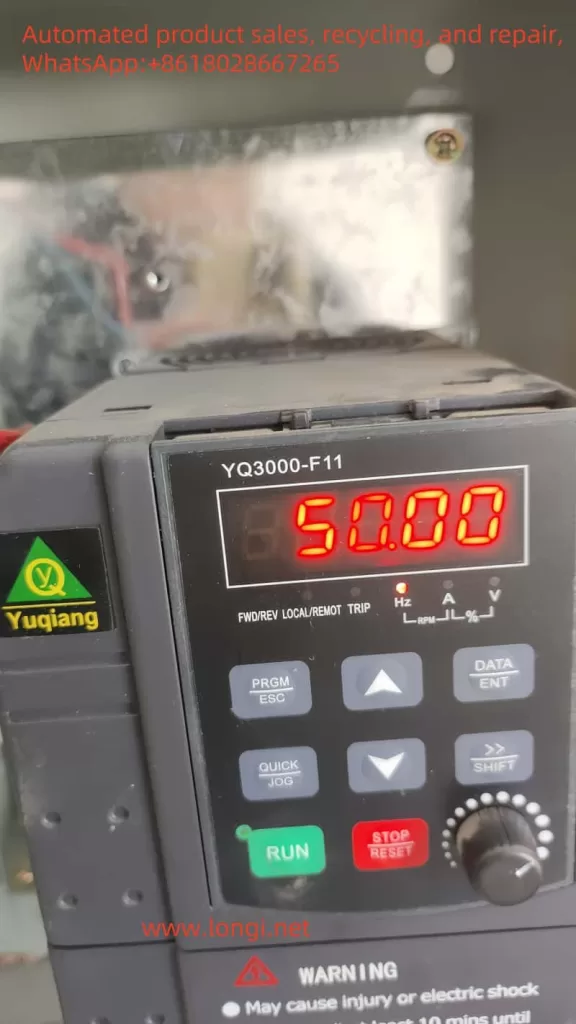

The YQ3000-F11 inverter from Yuqiang features an intuitive control panel, allowing users to set and adjust inverter parameters via buttons or knobs on the panel. Specific operation steps are as follows:

- Pre-startup Preparation: Close the air switch, observe whether there are abnormal displays on the inverter keyboard display, listen for any unusual sounds or vibrations within the inverter, and check for any unusual odors.

- Parameter Setting: According to the rated power and operating conditions of the motor, set the inverter’s maximum output frequency, start frequency, acceleration time, deceleration time, and other parameters via the control panel to ensure smooth and reliable inverter operation.

- Startup and Speed Adjustment: Set the inverter’s startup mode to manual or automatic. In automatic mode, the inverter will automatically start the motor based on preset parameters. After the motor starts, the speed can be adjusted via speed adjustment buttons or knobs on the control panel. The speed adjustment method may vary depending on the inverter model and display interface.

II. Method to Restore Factory Default Settings

When the inverter settings are incorrect or a reset is needed, the parameters can be restored to factory defaults through the following two methods:

- Method 1: While the inverter is powered off, press and hold three combination keys simultaneously. Then, turn on the inverter power switch. Release the keys shortly after, and the inverter will restore its factory parameters.

- Method 2: Follow specific operating steps via the panel control to select the mode, switch parameters, and then press and hold the SET key to restore factory defaults.

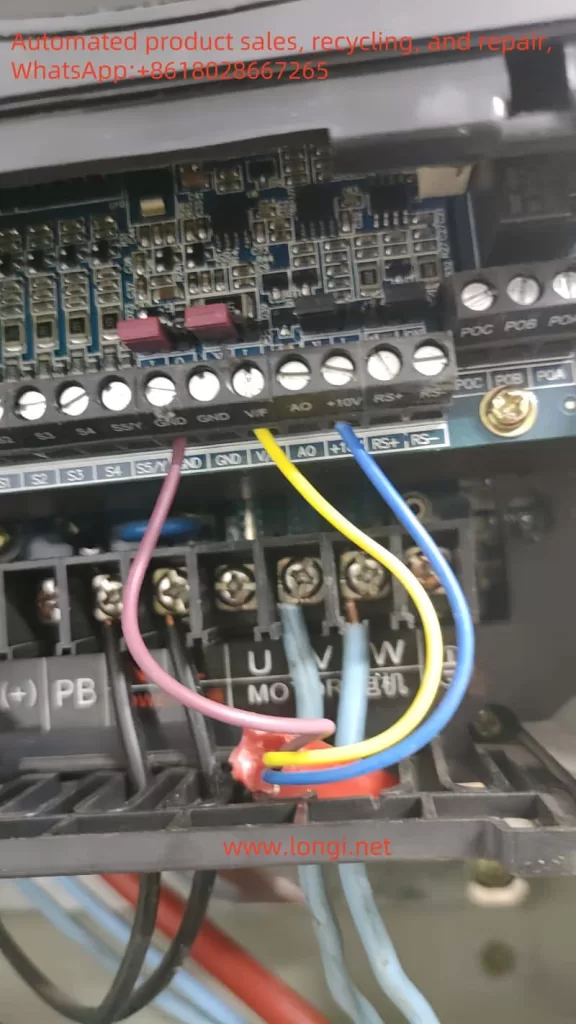

III. Specific Wiring and Parameter Settings for Terminal Forward/Reverse Rotation and External Potentiometer Speed Adjustment

The YQ3000-F11 inverter from Yuqiang supports motor forward/reverse rotation and external potentiometer speed adjustment via terminals. Specific wiring and parameter settings are as follows:

- Forward/Reverse Wiring:

- Connect the positive and negative terminals of the motor to the corresponding terminals on the inverter according to the terminal wiring diagram.

- Set the forward/reverse parameters (e.g., P001) as needed, enabling the inverter to achieve motor forward/reverse rotation based on control signals.

- External Potentiometer Speed Adjustment Wiring:

- Connect the output terminal of the external potentiometer to the AI1 (or other adjustable input terminal) of the inverter.

- Set AI1 as the speed reference input channel in the inverter parameters and adjust related parameters (e.g., P006) to achieve potentiometer speed adjustment.

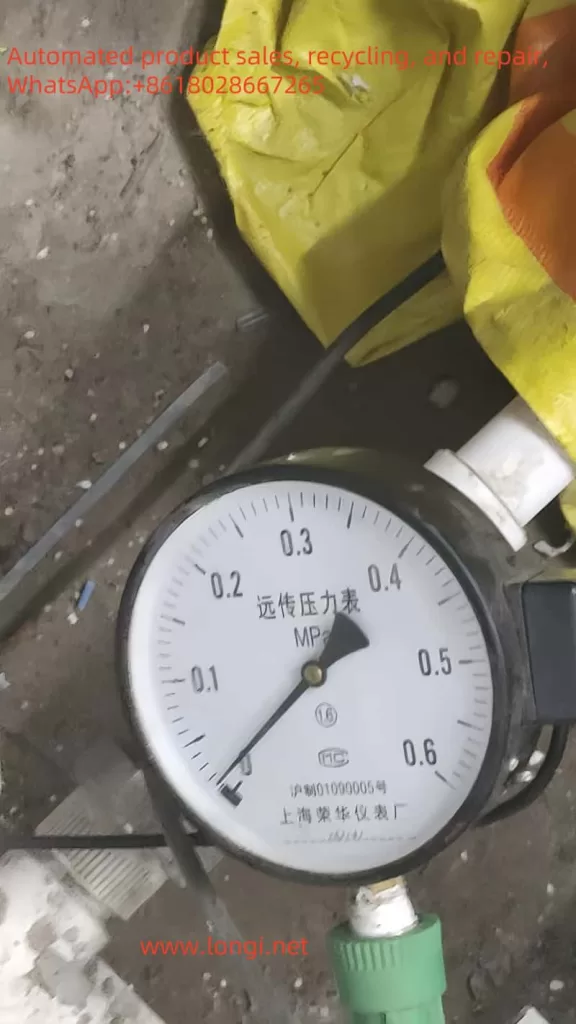

IV. PID Function Application Method for Constant Pressure Water Supply

On a single-pump constant pressure water supply system, the YQ3000-F11 inverter from Yuqiang can achieve single-loop closed-loop pressure control via the PID function. Specific steps are as follows:

- Wiring:

- Connect the output terminals of the pressure sensor (+10V, GND, and VF) to the corresponding control terminals of the inverter (e.g., AI1).

- Parameter Setting:

- Set P006=7 to select AI1 as the PID feedback input channel.

- Set P0902=0 to enable the PID function.

- Set PID parameters (e.g., proportional gain P, integral time I, derivative time D) as needed to achieve stable pressure control.

- Set the PID setpoint, which is the target pressure value. This is typically done by entering a specific numerical value in the inverter’s parameter settings.

- Debugging:

- During initial debugging, the proportional gain P can be preset to an intermediate to large value or temporarily left at the factory default.

- If the controlled physical quantity (i.e., pressure) oscillates near the target value, increase the integral time I. If oscillation persists, appropriately decrease the proportional gain P.

- If the controlled physical quantity is difficult to recover after changing, increase the proportional gain P. If recovery is still slow, appropriately decrease the integral time I or increase the derivative time D.

V. Fault Code Meanings and Solutions

When using the YQ3000-F11 inverter from Yuqiang, various fault codes may be encountered. These codes are usually displayed on the inverter’s display screen to help users quickly locate issues. Below are some common fault codes and their solutions:

- OC (Overcurrent):

- Cause: Excessive motor load, improper inverter parameter settings, etc.

- Solution: Check motor load, adjust inverter parameters, optimize motor matching, etc.

- OV (Overvoltage):

- Cause: Excessively high input voltage, internal inverter faults, etc.

- Solution: Check input voltage stability, replace the inverter, etc.

- OL (Overload):

- Cause: Motor overload, poor heat dissipation, etc.

- Solution: Check motor load, improve heat dissipation conditions, etc.

- OH (Overheat):

- Cause: Poor inverter heat dissipation, excessively high ambient temperature, etc.

- Solution: Improve heat dissipation conditions, reduce ambient temperature, etc.

In conclusion, the YQ3000-F11 inverter from Yuqiang boasts powerful functions and a wide range of applications. Through reasonable parameter settings and wiring methods, precise motor speed adjustment and stable control of constant pressure water supply systems can be achieved. At the same time, familiarity with fault code meanings and solutions also aids users in better maintaining and using the inverter.