I. Introduction to the ATV303 Series Inverter Operation Panel

The Schneider ATV303 series inverter’s operation panel (also known as the display terminal or HMI) features an intuitive interface, allowing users to easily set parameters, monitor operational status, and troubleshoot errors. The primary functions of the operation panel include:

- Display Screen: Displays the current status, parameter values, error messages, etc., of the inverter.

- Navigation Buttons: Used to navigate between menus and parameters, and to adjust parameter values.

- Mode Button: Switches between “Given” (rEF), “Monitor” (MOn), and “Configuration” (ConF) modes.

- Stop/Reset Button: Stops motor operation or resets faults under certain conditions.

- Run Button: Starts motor operation.

Setting and Removing Passwords

To prevent unauthorized access, users can set a password for the inverter. Here’s how:

- Enter “Configuration” mode (ConF).

- Select the “Maintenance” menu (900-).

- Locate the “HMI Password” parameter (999).

- Enter the desired password value (range: 2-9999) and press the “Confirm” button to save.

To remove the password, simply set the “HMI Password” parameter (999) to “OFF”.

Restoring Factory Settings

To reset the inverter’s parameters to their factory defaults, follow these steps:

- Enter “Configuration” mode (ConF).

- Select the “Store/Restore Parameter Sets” menu.

- Set the “Factory/Restore Customer Parameter Settings” parameter (102) to “64”. The inverter will restart automatically and apply the factory settings.

II. Terminal Forward/Reverse Control and External Potentiometer Speed Regulation

Terminal Forward/Reverse Control

To achieve motor forward/reverse control via the inverter’s control terminals, follow these setup and wiring steps:

- Parameter Settings:

- Enter “Configuration” mode (ConF).

- Select the “Input/Output” menu (200-).

- Set the “Control Type” parameter (201) to “2-wire control” or “3-wire control”.

- For “2-wire control”, configure the “2-wire Control” parameter (202), e.g., “Forward Priority”.

- Set the “Reverse” parameter (503) to specify which logic input terminal controls reversal (e.g., LI2H for LI2 high level reversal).

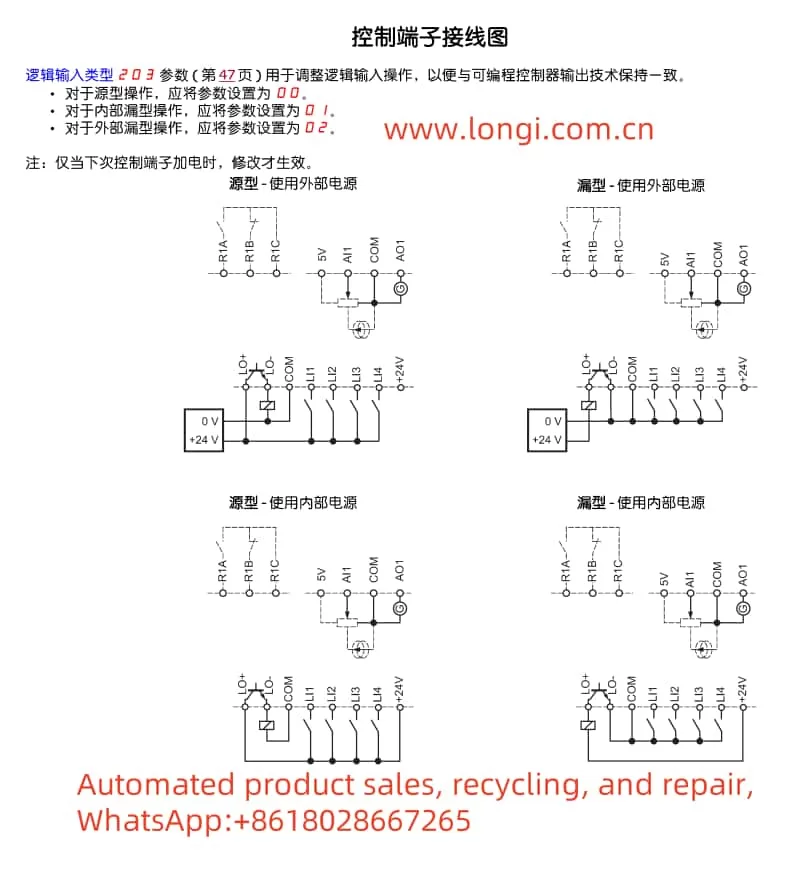

- Wiring:

- Connect the motor forward control terminal (e.g., LI1) to the forward control signal source.

- Connect the motor reverse control terminal (e.g., LI2, based on parameter settings) to the reverse control signal source.

- Ensure all control signal sources are passive dry contacts or provide appropriate level signals.

External Potentiometer Speed Regulation

To regulate inverter speed using an external potentiometer, configure the following parameters and connect the corresponding terminals:

- Parameter Settings:

- Enter “Configuration” mode (ConF).

- Select the “Control” menu (400-).

- Set the “Given Channel 1” parameter (401) to “183” to receive speed input via analog input AI1.

- Set the “AI1 Type” parameter (204.0) to “Voltage” or “Current” based on the external potentiometer’s output type.

- For current output, also set the “0% AI1 Current Ratio Parameter” (204.1) and “AI1 Current Calibration Parameter 100%” (204.2).

- Wiring:

- Connect the external potentiometer’s output terminal to the inverter’s analog input terminal AI1.

- Connect the external potentiometer’s power terminals (if needed) to the inverter’s +5V and COM terminals, or provide an external power supply.

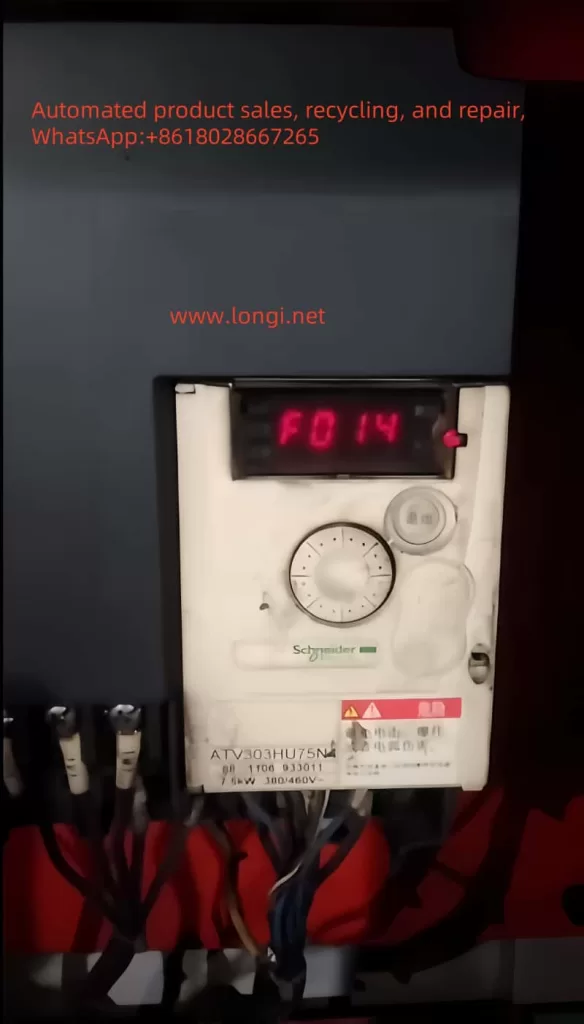

III. F014 Fault Resolution Method

F014 Fault Overview

The F014 fault indicates that one phase is missing from the inverter’s output to the motor. This fault can cause abnormal motor operation or even damage to the motor and inverter.

Mechanism of Occurrence

The primary mechanisms behind the output phase loss fault include:

- Loose or Poor Output Terminal Connections: Loose or poor contact between the inverter output terminals and motor connection terminals may prevent the transmission of electrical energy in one phase.

- Motor or Cable Faults: Internal motor winding damage or cable breaks can also lead to output phase loss.

- Inverter Internal Faults: Damage to power devices or control circuit faults within the inverter can cause output phase loss.

Repair Method

To resolve the F014 fault, follow these troubleshooting steps:

- Check Output Terminal Connections: Verify that the connections between the inverter output terminals and motor connection terminals are secure and free from loose or poor contacts.

- Inspect the Motor and Cable: Use a multimeter or other tool to check the continuity of the motor windings and cables, ensuring there are no breaks or shorts.

- Examine the Inverter Internals: If the above checks are clear, the fault may lie within the inverter. Disassemble and inspect the inverter for damaged power devices or control circuit faults, and perform necessary repairs or replacements.

- Re-execute Autotuning: After ruling out hardware faults, re-execute the inverter’s autotuning process to ensure correct parameter settings and normal motor operation.

By following these steps, users can effectively resolve the F014 fault on the ATV303 series inverter and restore normal device operation. Regular inspections and maintenance of the inverter are recommended to prevent similar faults from occurring.