I. Introduction to Operation Panel Functions and Settings

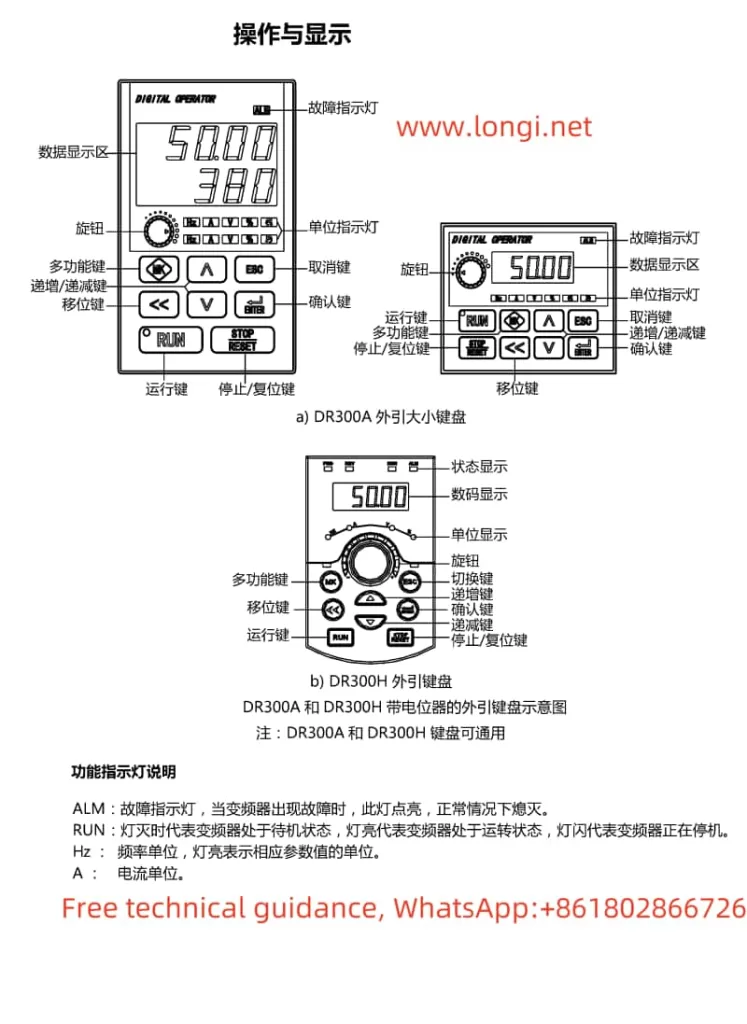

The operation panel of the Lijia DR300A inverter is its core control unit, providing an intuitive and user-friendly interface. The panel includes multiple function keys and indicator lights for monitoring and controlling the inverter’s operating status.

1. Password Setting and Keyboard Locking

To ensure device security, the DR300A supports user password protection. To set a password, first enter the parameter setting interface (Group F4), locate the F4.31 parameter item, and set its value to a non-zero value, which will be the user password. To disable password protection, simply reset F4.31 to 0.

The keyboard locking function prevents accidental operation. To enable locking, set the F4.25 parameter item to a non-zero value. To unlock, simultaneously press and hold the “<<” key and the “V” key for more than 2 seconds.

2. Factory Settings Restoration

If you need to restore the inverter parameters to their factory settings, you can set the F0.08 parameter item to “Parameter Restore Mode 1” or “Parameter Restore Mode 2”. The former does not include analog input/output offset parameters, while the latter does. Additionally, you can choose to “Clear Historical Information” to delete fault records and other historical data.

3. Macro Setting Selection

The DR300A offers multiple application macros to meet different needs. To select the “Power Winch Application Macro”, for example, navigate to the F0.04 parameter item and set its value to 6. This will automatically configure the inverter to meet the specific control requirements of power winch equipment.

II. Terminal Start, Forward/Reverse Control, and Speed Adjustment Settings

1. Terminal Start and Forward/Reverse Control

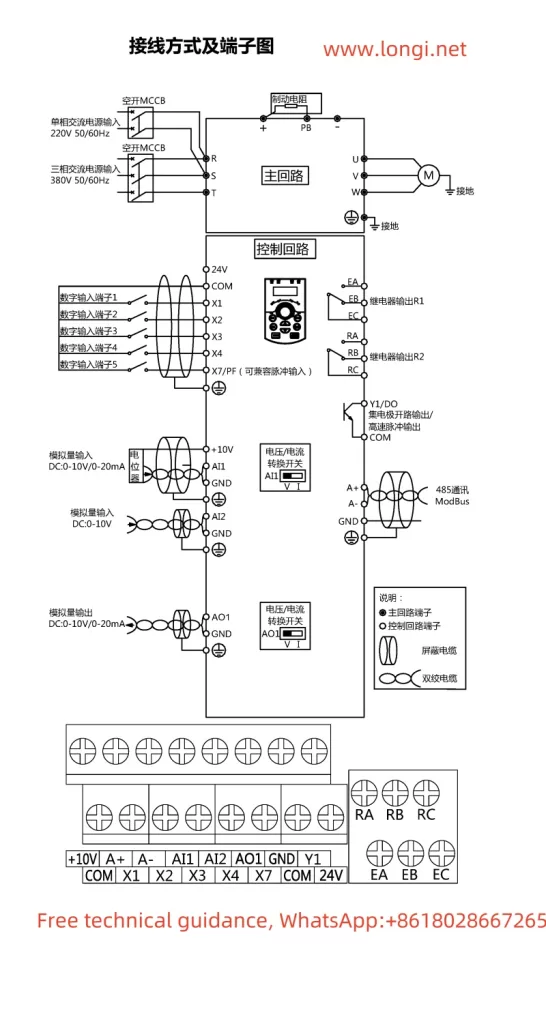

The DR300A supports external terminal start and control of motor forward/reverse rotation. First, set the F0.05 parameter item to 1 (External Terminal Control). Then, connect external switches or relays to the corresponding terminals (e.g., FWD for forward rotation, REV for reverse rotation) to control the motor’s running direction.

2. External Potentiometer Speed Adjustment

To adjust motor speed via an external potentiometer, set the speed reference to analog input. Navigate to the F0.08 parameter item and select AI0, AI1, or AI2 as the speed source. Next, connect the external potentiometer to the corresponding analog input terminal (AI0, AI1, or AI2) and GND. Additionally, set parameters such as F2.15 to F2.20 according to the potentiometer’s output range to match the potentiometer’s minimum/maximum input voltage with the inverter’s speed range.

III. Fault Code Analysis and Resolution

The DR300A inverter features comprehensive fault diagnosis capabilities, enabling real-time monitoring and reporting of device status. When a fault occurs, the “ALM” indicator light on the panel will illuminate, along with the corresponding error code.

1. Common Fault Codes

- Err.01: Inverter Unit Protection, possible causes include overcurrent, overheating, etc. Solutions include checking motor load, cooling conditions, and cable connections.

- Err.05: Acceleration Overcurrent, possibly caused by motor stall or excessive load. Check for motor and mechanical blockages, adjust the load, or increase acceleration time.

- Err.13: Communication Fault, check the communication line, baud rate, and address settings for correctness.

2. Fault Troubleshooting Steps

- Initial Check: Confirm that the power supply is normal and there are no short circuits or open circuits.

- Parameter Review: Check that relevant parameter settings are correct, such as acceleration time, deceleration time, motor parameters, etc.

- Equipment Inspection: Observe whether the motor runs smoothly and listen for any abnormal noises or vibrations.

- Log Analysis: Review the inverter’s fault records to analyze historical fault information and pinpoint the root cause of the problem.

IV. Conclusion

The Lijia DR300A Inverter User Manual is an important reference for operating and maintaining this equipment. By mastering the operation panel functions, properly setting parameters, and quickly diagnosing faults, you can ensure efficient and stable operation of the inverter. Both beginners and experienced engineers can benefit from the practical guidance and assistance provided in the manual. In practical applications, it is recommended to flexibly configure and optimize settings based on specific equipment conditions and actual needs to achieve the best control effects.