The C-LIN XLP6000 series of inverters, as a high-performance general-purpose vector control inverter, is widely used in various industrial control applications due to its excellent motor control performance and flexible operation methods. This article aims to provide users with a comprehensive guide on operating the C-LIN XLP6000 series inverter based on its user manual.

1. Introduction to the Functionality of the Inverter Operation Panel

The operation panel of the C-LIN XLP6000 series inverter is equipped with various functions to facilitate user operation and monitoring. It includes:

- Password Setting and Reset:

- To set a password, users can modify the parameter P0.00 in the function parameter settings. Note that passwords with values of 0 to 9 do not require protection, while setting a password successfully requires a wait of 3 minutes before it takes effect.

- To reset the password, users can set P0.00 back to its default value (0).

- Parameter Locking:

- Users can enable parameter locking by setting the parameter P0.09 to 2, which will prevent unauthorized modifications to parameters.

- Parameter Initialization:

- To initialize parameters, users can set P0.09 to 2. This will restore all user parameters to their factory default settings, except for motor parameters.

2. Terminal Control for Forward/Reverse Rotation and External Potentiometer Speed Regulation

To achieve forward/reverse rotation control and external potentiometer speed regulation, users need to properly wire the relevant terminals and configure the corresponding parameters.

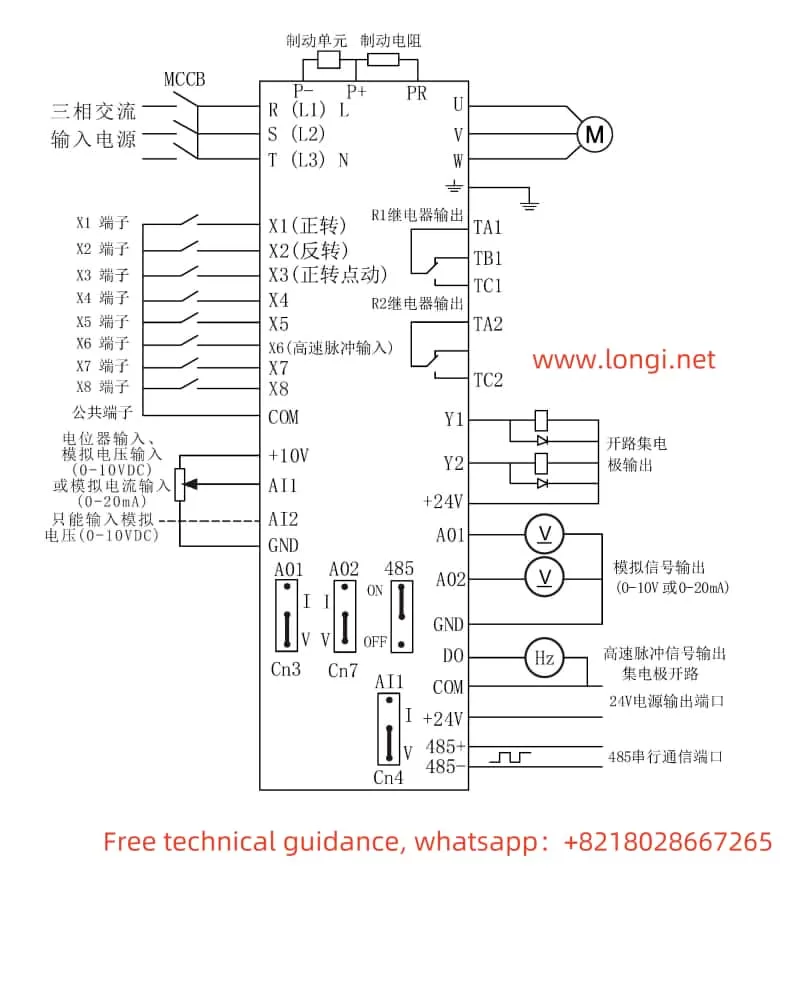

- Wiring Instructions:

- Forward/Reverse Rotation Control:

- Connect the forward and reverse control terminals (X1 and X2) to the corresponding switches or relays.

- Ensure that the common terminal (COM) is properly grounded.

- In the function parameter settings, set P0.21 to determine the default direction when using the operation panel.

- External Potentiometer Speed Regulation:

- Connect one end of the potentiometer to the power supply (e.g., +10V and GND).

- Connect the other end of the potentiometer to the analog input terminal (AI1).

- In the function parameter settings, ensure that AI1 is configured to receive analog voltage input and set the corresponding range.

- Forward/Reverse Rotation Control:

- Specific Terminals:

- Forward/Reverse Control: X1 (forward), X2 (reverse), COM (common)

- External Potentiometer: AI1 (analog input), +10V (power supply), GND (ground)

- Parameters to Be Set:

- P0.06: Run command channel selection (set to 0 for operation panel control, 1 for terminal control, etc.)

- P0.07: Frequency setting channel selection (set to 1 for analog voltage input, etc.)

- P6.00: AI1 input type selection (set to 0 for voltage input)

- P6.01: AI1 input range setting

By following the above steps, users can effectively utilize the C-LIN XLP6000 series inverter for forward/reverse rotation control and external potentiometer speed regulation, enhancing the flexibility and efficiency of their industrial control systems.