The Zhengchuan ZC300 series frequency converter is a high-performance frequency control device known for its high torque, high precision, wide speed range, and low noise. It is widely used in equipment manufacturing and end-user applications for speed control, energy saving, protection, and automatic control. To assist users in better understanding and utilizing this frequency converter, the following is a detailed user manual guide based on the Zhengchuan ZC300 series frequency converter manual.

I. Introduction to the Frequency Converter Operation Panel and Parameter Settings

1. Operation Panel Function Introduction

The operation panel of the Zhengchuan ZC300 series frequency converter mainly includes a display screen, function keys (MENU, ENT, UP/DOWN arrow keys, etc.), and status indicators. By operating these keys, users can access and modify various parameters of the frequency converter for precise control.

2. Parameter Locking and Password Setting

To ensure that the frequency converter parameters are not changed arbitrarily, the Zhengchuan frequency converter provides a parameter locking function. The specific operation steps are as follows:

- First, enter the parameter setting interface through the operation panel.

- Find the parameter that needs to be locked (such as P0.07) and set its value to 1.

- Press the MENU key twice to exit the parameter setting interface. At this point, the parameter is locked.

To unlock the parameter, simultaneously press and hold the first function key and the red stop key for 8 seconds. The screen will display a prompt indicating successful unlocking.

Password setting typically involves modifying specific parameters, and the specific method may vary depending on the model. Please refer to the detailed instructions in the user manual.

3. Parameter Initialization

Parameter initialization is the process of restoring the frequency converter to its factory settings, which helps restore the device to normal operation when the parameter settings are confused. The method for initializing parameters is as follows:

- Enter the parameter setting interface and find the function code related to initialization (such as P0.00).

- According to the instructions in the user manual, set the value of the function code to the corresponding initialization option (e.g., 2 indicates restoring all user parameters to factory settings).

- After confirming the setting, exit the parameter setting interface, and the frequency converter will automatically restore to its factory settings.

II. Terminal Forward/Reverse Control and External Potentiometer Speed Adjustment

1. Terminal Forward/Reverse Control

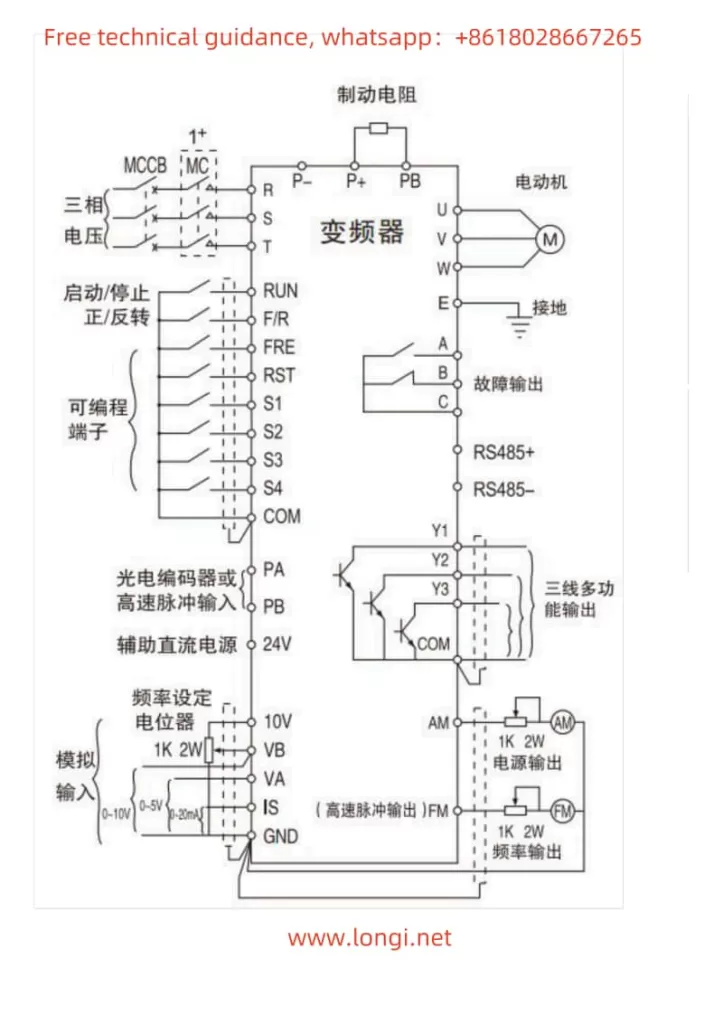

The Zhengchuan ZC300 series frequency converter supports forward/reverse control of the motor through terminals. The specific wiring and setting methods are as follows:

- Wiring: Connect the three wires of the three-phase motor to the UVW terminals of the frequency converter. At the same time, connect the intermediate relays KA1 and KA2 controlling forward and reverse to the STF and STR terminals of the frequency converter, respectively. Additionally, short-circuit the SD terminal with the common terminal to achieve start control.

- Setting: Enter the parameter setting interface, find the parameter related to forward/reverse control (such as the run command channel selection), and set it to the external terminal control mode.

2. External Potentiometer Speed Adjustment

An external potentiometer can be used to adjust the output frequency of the frequency converter, thereby achieving precise control of the motor speed. The specific wiring and setting methods are as follows:

- Wiring: Connect the three terminals of the potentiometer to the 10V, V, and GND terminals of the frequency converter. Among them, the 10V terminal provides positive power for the potentiometer, the V terminal is the output terminal of the potentiometer, and the GND terminal is the grounding terminal.

- Setting: Enter the parameter setting interface, find the frequency setting selection parameter, and set it to the external terminal mode. At this point, the output frequency of the frequency converter will change with the rotation angle of the potentiometer.

III. Fault Codes and Their Handling

The Zhengchuan ZC300 series frequency converter has a comprehensive fault detection and diagnosis function, capable of displaying fault codes in real-time and taking corresponding protective measures. The following are some common fault codes, their meanings, and handling methods:

1. OCF (Overcurrent Fault of the Frequency Converter)

- Meaning: Incorrect input of motor nameplate data or excessive load causing excessive output current of the frequency converter.

- Handling Method: Check whether the motor nameplate data entered in the settings and motor control menu is correct; check whether the frequency converter selection matches the motor and load; check whether the motor is locked or the machinery is jammed.

2. SCF (Motor Short-Circuit Fault)

- Meaning: Insulation issues in the motor or the cable from the frequency converter to the motor causing a short circuit.

- Handling Method: Check the insulation of the cable between the frequency converter and the motor; check the motor insulation; if the cable is too long, use a motor reactor or sine wave filter to reduce grounding leakage current.

3. OBF (Over-Braking Fault)

- Meaning: Sudden increase in the internal DC bus voltage of the frequency converter due to excessive braking or excessive load inertia.

- Handling Method: Increase the deceleration time of the frequency converter; activate the deceleration time adaptive function; add a braking resistor and calculate the resistance value and power of the braking resistor based on actual requirements.

4. OLF (Motor Overload Fault)

- Meaning: Excessive current in the motor triggers the motor thermal protection inside the frequency converter.

- Handling Method: Check the load condition of the motor; check the setting of the motor thermal protection parameter of the frequency converter; wait for the motor to cool down before starting it again.

5. OPF (Motor Phase Loss Fault)

- Meaning: The frequency converter is not connected to the motor or the motor power does not match the frequency converter power, resulting in the inability to detect motor current.

- Handling Method: Check the connection between the frequency converter and the motor; turn off the motor phase loss protection function of the frequency converter (e.g., for small motor testing); check whether the settings for the motor rated voltage, rated current, and IR stator voltage drop compensation parameters are correct.

In addition, there are other fault codes such as OSF (Overvoltage Fault of Input), SLF (Communication Fault of Frequency Converter), USF (Undervoltage Fault of Frequency Converter), and PHF (Input Phase Loss Fault of Frequency Converter), each with its specific meaning and handling method. Users should closely monitor the operating status of the frequency converter during use to detect and handle faults in a timely manner.

Conclusion

The Zhengchuan ZC300 series frequency converter, as a high-performance frequency control device, offers various practical functions to meet the needs of different users. This article provides a detailed introduction to the operation panel functions, parameter setting methods, wiring and setting methods for terminal forward/reverse control and external potentiometer speed adjustment, as well as the meanings and handling methods of common fault codes. We hope this user manual guide can help users better understand and utilize the Zhengchuan ZC300 series frequency converter.