I. Introduction to the Operation Panel Functions

The operation panel of the Tai’an Inverter N2 series is designed to be intuitive and feature-rich, facilitating various settings and monitoring for users. The panel primarily includes the following function keys and indicator lights:

- FREQ.SET: Used to set the output frequency.

- ▲▼: Increase or decrease the set value.

- READ: Read the current display content.

- ENTER: Confirm the settings.

- RUN: Start the inverter.

- STOP: Stop the inverter.

- DSP: Switch between display contents, such as frequency, speed, linear velocity, etc.

- FUN: Enter the function setting mode.

- FWD/REV: Forward/Reverse indicator lights, showing the current operating direction.

- Hz/RPM/VOLT/AMP: Indicate frequency, speed, voltage, and current, respectively.

II. Password Setting and Parameter Access Restrictions

To ensure the security of the inverter settings, the N2 series provides a password protection function. Users can follow these steps to set and remove passwords:

- Setting a Password:

- Enter the function setting mode (FUN).

- Use the ▲▼ keys to select the password setting option.

- Enter the password value using the FREQ.SET key.

- Press the ENTER key to confirm.

- Removing a Password:

- Enter the function setting mode (FUN).

- Select the password setting option.

- Set the password value to 0 and press the ENTER key to confirm.

- Parameter Access Restrictions:

- Users can restrict access to frequency parameters by setting parameter F_004. When F_004 is set to XXX1, frequency parameters are locked and cannot be modified.

- Parameter Initialization:

- Users can initialize the inverter parameters by setting parameter F_123. Setting F_123 to 1111 or 1110 will restore the inverter to its factory settings.

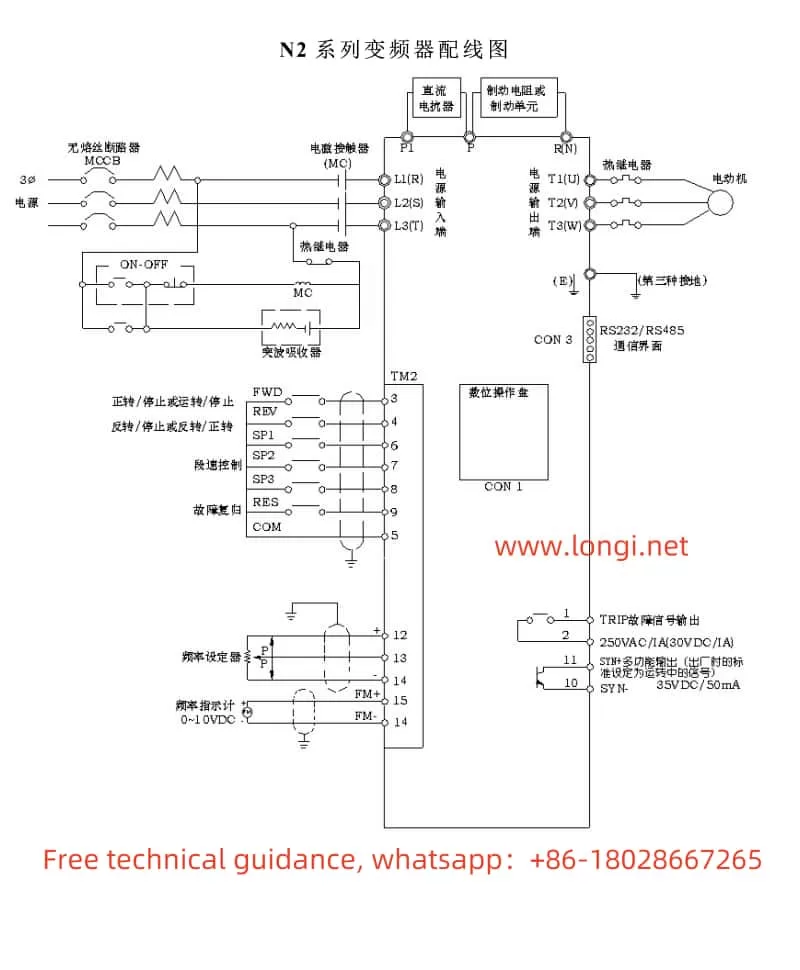

III. External Terminal Forward/Reverse Control and External Potentiometer Speed Regulation

The N2 series inverter supports forward/reverse control and external potentiometer speed regulation through external terminals. Specific settings and wiring are as follows:

- Forward/Reverse Control:

- Parameter Setting: Set F_003 to XX01 (forward/reverse mode).

- Terminal Wiring: Connect the forward control signal to terminal 3 of TM2, the reverse control signal to terminal 4, and the common terminal to terminal 5.

- External Potentiometer Speed Regulation:

- Parameter Setting: Set F_011 to 1 (frequency instruction set by the potentiometer on the panel) or 2 (frequency instruction set by the potentiometer or analog signal on the TM2 multifunction terminal).

- Terminal Wiring: Connect the output terminal of the external potentiometer to terminal 13 of TM2 (analog input point), and the common point of the analog signal to terminal 14.

IV. Fault Codes and Solutions

During operation, the N2 series inverter may display various fault codes. Users need to take corresponding measures based on the code meanings:

- OC (Overcurrent):

- Meaning: The output current of the motor or inverter exceeds the rated value.

- Solution: Check if the motor is overloaded, adjust the acceleration time or V/F curve, and ensure that the motor matches the inverter capacity.

- OL1 (Motor Overload):

- Meaning: The motor overload protection has activated.

- Solution: Check if the load is too heavy, adjust the motor protection parameters F_069 and F_070, and ensure that the motor operates within the rated load.

- OL2 (Inverter Overload):

- Meaning: The output current of the inverter exceeds the rated value for an extended period.

- Solution: Check if the load is too heavy, adjust the acceleration time, or increase the inverter capacity.

- OV (Overvoltage):

- Meaning: The DC bus voltage of the inverter is too high.

- Solution: Check if the power supply voltage is too high, adjust the deceleration time, or install a braking resistor.

- LV (Low Voltage):

- Meaning: The input power supply voltage is too low.

- Solution: Check if the power supply voltage is normal and adjust the allowable instantaneous stop time parameter F_031.

- OH (Heat Sink Overheat):

- Meaning: The temperature of the inverter heat sink is too high.

- Solution: Check if the ventilation conditions are good, clean the heat sink dust, reduce the load, or increase the inverter capacity.

Through this operation guide, users can better understand and use the Tai’an Inverter N2 series, ensuring the normal operation and efficient energy saving of the inverter. In practical applications, users should also reasonably set the inverter parameters according to specific loads and process requirements to achieve the best control effect.