The Huayuan Z230 series is a high-performance inverter designed specifically for electric hoists, widely used in lifting, traversing, and slewing control of small lifting equipment. This article provides a detailed introduction to the operation panel functions, parameter settings, external control implementation, and fault handling of the Z230 series inverter, helping users better understand and use the device.

I. Introduction to the Operation Panel

1. Overview of the Operation Panel

The operation panel of the Huayuan Z230 series inverter integrates a display screen, indicator lights, and multifunctional buttons. Users can perform parameter settings, operation control, and fault diagnosis through the panel. The main functions are as follows:

- Display Screen: Used to display output frequency, current, parameter settings, and fault codes.

- Indicator Lights: Includes power indicator (Power) and inverter status indicator (Status), which lights up during operation and turns off when stopped.

- Multifunctional Keys: Includes programming key (PRG), confirmation key (ENT), shift key (↑↓), run key (RUN), and stop/reset key (STOP), etc.

2. How to Restore Factory Parameters

When the inverter malfunctions or needs to be reconfigured, the factory parameters can be restored. The specific operations are as follows:

- Enter the parameter setting interface and find the function code P00.26.

- Set P00.26 = 1 to restore factory parameters (excluding motor parameters).

- Set P00.26 = 2 to restore factory parameters (including motor parameters).

3. How to Set a Password

To prevent unauthorized personnel from operating the inverter, a password can be set for protection. The specific steps are as follows:

- Enter the parameter setting interface and find the function code P07.11.

- Set P07.11 to a value between 0 and 65535, which will be the password.

- After setting, the password must be entered each time the parameter setting interface is accessed.

4. Motor Parameter Self-Learning

Motor parameter self-learning is a key step to ensure the matching between the inverter and the motor. The specific operations are as follows:

- Set the function code P00.25 = 3 to perform static complete tuning.

- Press the run key, and the inverter will automatically start motor parameter self-learning, with the display showing “TUNE”.

- During the self-learning process, the motor will emit a howling sound and vibrate, which is normal.

- After the self-learning is completed, the display will exit the “TUNE” state, and the parameter tuning is completed.

II. Implementation of External Control

1. External Terminal Forward and Reverse Control

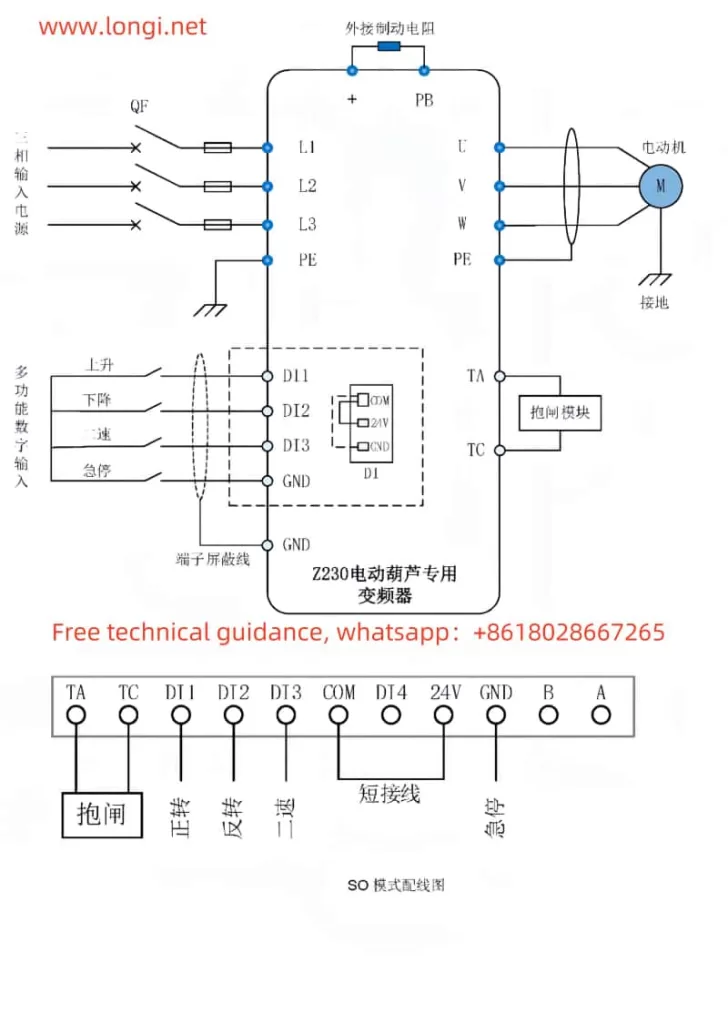

The Huayuan Z230 series inverter supports forward and reverse control through external terminals. The specific wiring and parameter settings are as follows:

Wiring:

- DI1 Terminal: Forward running command.

- DI2 Terminal: Reverse running command.

Parameter Settings:

- Set P00.01 = 1 to select the terminal command channel.

- Set P05.00 = 1 to select the function of DI1 terminal as forward running.

- Set P05.01 = 2 to select the function of DI2 terminal as reverse running.

2. External Terminal Multi-Speed Control

Multi-speed control can be achieved through external terminals. The specific wiring and parameter settings are as follows:

Wiring:

- DI3 Terminal: Multi-command terminal 1.

- DI4 Terminal: Multi-command terminal 2.

Parameter Settings:

- Set P00.02 = 4 to select the multi-command mode.

- Set P05.02 = 12 to select the function of DI3 terminal as multi-command terminal 1.

- Set P05.03 = 13 to select the function of DI4 terminal as multi-command terminal 2.

- Set P11.00 and P11.01 to different speed values, corresponding to the speeds of the multi-commands.

3. Use of Brake and Braking Modules

The brake and braking modules are important functions of the inverter, used to enhance the safety and stability of the equipment.

Brake Module Parameter Settings:

- Set P06.00 = 39 to set the inverter function as brake output.

- Set P19.00 = 1 to enable the brake output function.

- Set P19.01 = 50 for the brake release current threshold.

- Set P19.02 = 10 for the brake application current threshold.

- Set P19.03 = 1.00 for the brake release frequency threshold.

- Set P19.04 = 2.00 for the brake application frequency threshold.

Braking Module Parameter Settings:

- Set P09.15 = 1 to enable energy-consuming braking.

- Set P09.16 = 160 for the energy-consuming braking voltage point.

- Set P09.17 = 100 for the energy-consuming braking usage rate.

III. Fault Codes and Handling Methods

The Huayuan Z230 series inverter may encounter various faults during operation. Users can quickly locate problems through the fault codes displayed on the screen. The following are common fault codes and handling methods:

1. Overvoltage During Deceleration

- Causes: Input voltage is too high, external force drags the motor during deceleration, deceleration time is too short, or no braking unit is installed.

- Handling: Adjust the voltage to the normal range, increase the deceleration time, and install the braking unit and braking resistor.

2. Undervoltage

- Causes: Momentary power outage, low input voltage of the inverter, or abnormal rectifier bridge.

- Handling: Reset the fault, adjust the voltage to the normal range, and seek technical support.

3. Inverter Overload

- Causes: Excessive load, motor stalling, or undersized inverter selection.

- Handling: Reduce the load, check the motor and mechanical conditions, and select a larger capacity inverter.

4. Module Temperature Abnormality

- Causes: Excessively high or low ambient temperature, blocked air duct, fan failure, or damaged thermistor.

- Handling: Lower or raise the ambient temperature, clean the air duct, replace the fan or thermistor.

5. Motor Tuning Abnormality

- Causes: Motor parameters not set according to the nameplate or tuning process timeout.

- Handling: Correctly set the parameters according to the motor nameplate and check the wiring from the inverter to the motor.

IV. Conclusion

The Huayuan Z230 series inverter is a powerful and easy-to-operate inverter specifically designed for electric hoists. By reasonably setting parameters, correctly wiring, and promptly handling faults, users can fully utilize its performance, enhancing the stability and safety of the equipment. This article provides a detailed introduction to the operation panel functions, external control implementation methods, and fault handling of the inverter, aiming to provide valuable references for users. If any difficulties are encountered, it is recommended to contact the manufacturer’s technical support for professional assistance.