In modern industrial automation, FANUC CNC systems are widely used in CNC machine tools, robots, and a variety of automated equipment. Renowned for high reliability, precision, and scalability, FANUC products have gained the trust of manufacturing enterprises worldwide. Among the various alarms that can arise when using FANUC αi series drives (including servo amplifiers and spindle amplifiers), one of the most common and sometimes puzzling is the “AL-81” alarm. This article will focus on the meaning of the AL-81 alarm, the scenarios under which it appears, troubleshooting methods, and frequently asked questions. The aim is to help readers quickly and effectively carry out fault diagnosis and resolution.

I. The Meaning of the AL-81 Alarm

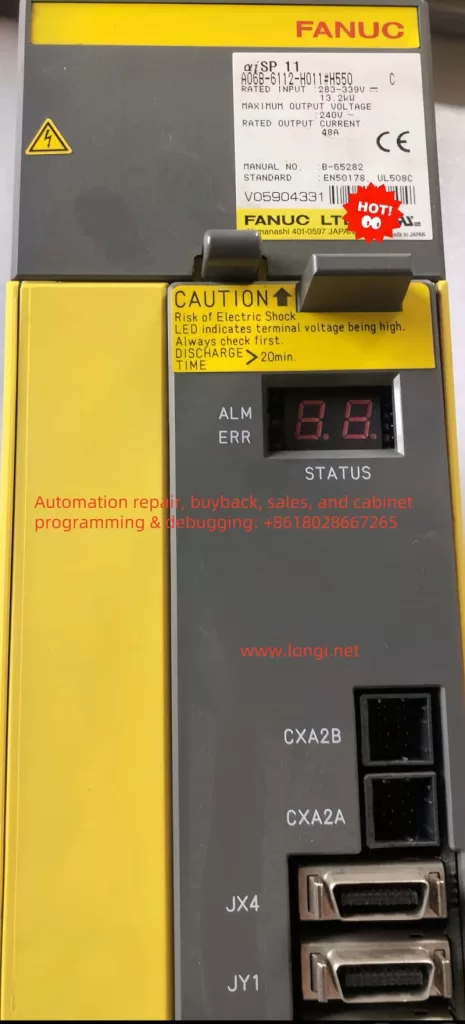

On FANUC αi SP (spindle drives) or αi SV (servo drives), the “81” alarm typically indicates that the drive has not completed its internal parameter initialization. In other words, the drive cannot properly recognize the axis number assigned to it by the CNC system, or the amplifier parameters necessary for operation have not yet been written to it. Under normal circumstances, a FANUC αi series drive will exchange data with the CNC system, including amplifier identification, servo/spindle parameters, and communication settings. If something goes wrong—such as a newly installed drive without parameter input, or an existing drive whose internal data has been cleared—the AL-81 alarm will remain active.

It is worth noting that this alarm typically appears just after the drive is powered on or reset, as the system checks for proper drive identification and parameter download. If the CNC controller cannot “recognize” the drive and transfer the correct parameters, the drive will report the AL-81 alarm and enter an inoperative alarm state. At this point, the user will see “AL-81” or a similar two-digit code on the drive’s panel or display.

II. Common Scenarios Leading to the Alarm

- Replacing a Drive without Completing Parameter Initialization

When an older αi series drive fails and is replaced with a new one, but no parameter-writing procedure is performed via the CNC’s maintenance mode, an AL-81 alarm will appear. A new drive generally has no specific axis parameters programmed from the factory and requires the CNC to download the necessary configuration data. - Parameter Loss after Main Board or System Component Initialization

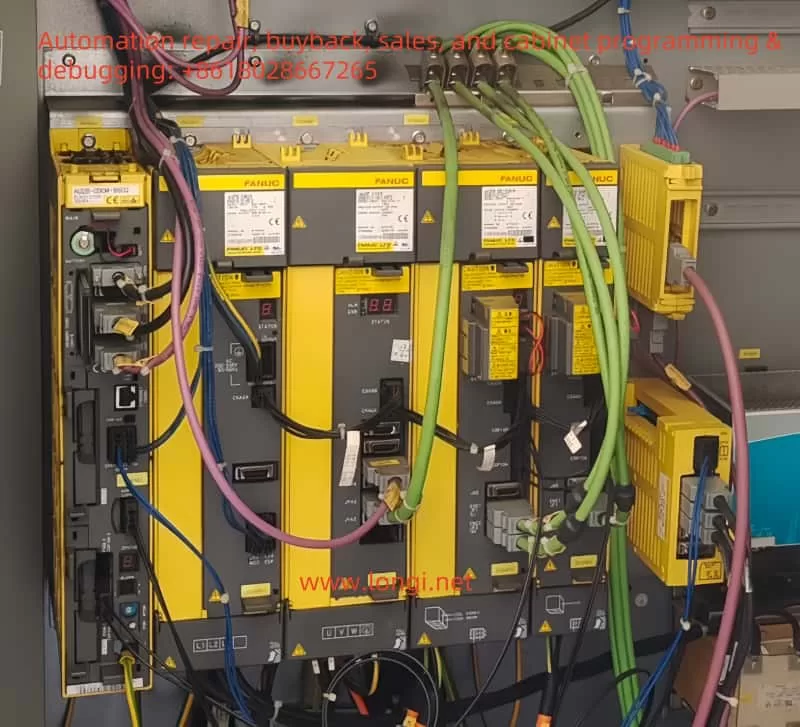

During maintenance or replacement of the CNC main board, or after restoring system data from a backup, certain critical files or parameters may fail to synchronize correctly with the drive. In particular, in multi-axis machine or multi-drive systems, the fiber-optic (FSSB) communication setup is crucial. If the sequence or configuration is not aligned, it may trigger the AL-81 alarm because the drive lacks the required internal identification parameters. - Incorrect Fiber-Optic Connections or Axis Number Assignments

In machines with multiple axes and multiple drives, the servo and spindle amplifiers typically communicate with the CNC via fiber-optic cables (FSSB channels). If the user changes the fiber-optic order or fails to match the correct axis assignments, the drive will not establish the proper correlation with the CNC upon power-up, triggering the AL-81 alarm. The system detects a mismatch between the drive’s internal ID and the CNC parameters, causing the alarm. - Drive Memory Failure or Hardware Incompatibility

Although less common, the drive’s internal memory may become damaged or its hardware may degrade after many years of operation, resulting in an inability to store parameters. Additionally, if the replacement drive model is significantly different from the original—due to a different power rating, for instance—simple parameter writing may not remedy the hardware discrepancy, leading to a persistent AL-81 or other alarms.

III. Troubleshooting and Resolution

- Perform Drive Initialization (AIF Parameter Writing)

- Enter the CNC’s maintenance mode (often called Maintenance Mode or a similar advanced-privilege screen) and locate the “Amplifier/Servo Initialization” or “AIF” option.

- Allow the system to automatically detect the new drive and download the required parameters into the amplifier. During this process, the CNC will scan for the drive, prompt to overwrite or write parameters, and generally require following machine-specific or manufacturer-provided instructions.

- After parameter writing is complete, shut down and then power the system back on. In most cases, the AL-81 alarm will clear automatically.

- Check Fiber-Optic (FSSB) Connections and Axis Configuration

- In multi-drive setups, the fiber-optic cables’ order and each drive’s designated axis numbers must match the CNC settings. For example, the spindle drive might be connected on the first channel, with servo drives following in subsequent channels.

- If you have disconnected the fiber-optic cables, carefully confirm their original sequence. Ensure each cable is reconnected to the correct amplifier port and that the CNC parameters reflect the correct axis.

- Some machine builders label drives or cables clearly, indicating which cable goes where, thus helping to avoid confusion when reattaching connections.

- Confirm Drive Model and Power Compatibility

- When replacing a drive, make sure you select a model that is compatible with the original, matching in power, rated current, and interface specifications. If there is a large difference between the old and new drives, parameter writing alone may not be sufficient to achieve normal operation.

- If you are uncertain about compatibility, refer to the original manufacturer’s technical manuals, data from the machine tool builder, or consult a professional engineer.

- Reset or Inspect the Drive Hardware

- If you have completed the initialization process and verified your connections, but the AL-81 alarm persists, you could try a more thorough reset of the drive.

- In FANUC systems, there are sometimes special methods or software tools required for deeper clearing or parameter-writing procedures. Refer to machine documentation or contact technical support for details.

- If no improvement is observed, you may suspect a genuine hardware fault in the drive itself and consider further inspection, factory repair, or replacement.

IV. Frequently Asked Questions

- Why do I sometimes see numbers like “51” or “B1” on the panel instead of “81”?

- Under certain lighting angles, display types, or different drive versions, digits like “8” and “B,” or “1” and “I,” can be visually confusing. Checking the official drive manual helps confirm the true alarm code is “81.”

- Is it a fault if the power supply unit (αiPS) displays “4” or another number?

- Many FANUC power supply units display internal status codes during normal operation, rather than error codes. Only when you see an “E” code on the power unit or abnormal indicator lights should you suspect a fault in the power supply.

- Consequently, if the αiPS only shows “4” (and not “E-xx” or similar), it generally indicates normal operation.

- If it is an absolute encoder issue, why is the alarm not AL-81?

- When an absolute encoder loses power or the battery voltage drops, you usually see alarms such as “bL,” “bF,” or other encoder-related messages at the CNC level. These are unrelated to the drive initialization issue represented by AL-81.

- Why does the alarm remain even after initialization?

- It’s possible that something went wrong during the initialization or parameter writing process—maybe the system failed to properly recognize the drive or the user skipped a critical step.

- Another possibility is that the physical connections (e.g., fiber-optic cables) remain incorrect: reversed connections, poor contact, or the wrong channel sequence.

- If these causes are ruled out, the drive hardware itself may be faulty, requiring more advanced inspection or repair.

V. Conclusion

When an AL-81 alarm appears on a FANUC αi series drive in a CNC machine tool or automated production line, it does not necessarily mean the hardware is broken. More often, it is a common fault triggered by incomplete initialization or parameter mismatch. By performing parameter writing on the drive, checking fiber-optic connections, and confirming model compatibility, most AL-81 alarms can be resolved within a short time. If all settings have been validated and the alarm still will not clear, it is advisable to investigate possible hardware failure in the drive and, if necessary, consult professional technical support or send the drive for factory repair.

When using a FANUC CNC system, it is crucial to maintain complete machine documentation and service records, as well as to perform regular backups and checks. Doing so ensures that, when any fault arises—whether AL-81 or otherwise—existing information can be used to pinpoint the cause quickly and to restore production following the proper guidelines, saving both time and resources for the enterprise.