Abstract

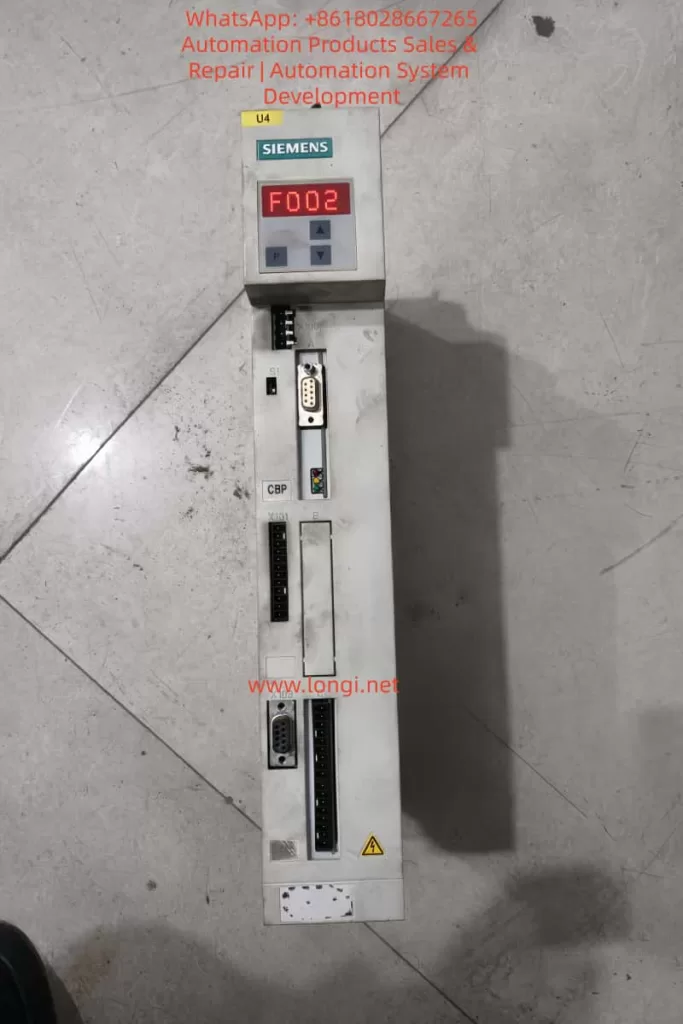

The Siemens Masterdrives VC series is a high-performance vector-controlled drive system widely used in industrial automation, traction systems, and hoisting equipment. Fault code F002 indicates a precharging fault, meaning that the DC link voltage fails to reach the required threshold within the specified time (typically 3 seconds). This fault usually occurs when the DC bus voltage does not reach approximately 80% of (P071 × 1.34).

The F002 fault is commonly related to power supply issues, faulty contactors, damaged precharge circuits, or incorrect parameter configuration. It prevents the drive from completing the startup sequence, causing system downtime and potential production losses.

This article provides a comprehensive technical guide covering the working principle, fault mechanism, diagnostic methods, corrective actions, real-world case studies, and preventive maintenance strategies. The content is based on Siemens documentation and field experience, and is intended to help engineers quickly locate root causes and restore reliable operation.

1. Introduction

In modern industrial environments, variable frequency drives such as the Siemens Masterdrives VC series are core components for precision motor control. These drives support multiple control modes ranging from open-loop V/Hz to closed-loop vector control, enabling accurate speed and torque regulation for asynchronous and synchronous motors.

The F002 precharging fault is one of the most frequently encountered startup faults. It occurs when the DC link voltage does not build up correctly during power-on. This fault not only prevents the drive from starting, but can also indicate deeper electrical or hardware issues, such as unstable incoming power, defective precharge resistors, or main contactor malfunctions.

Industrial statistics show that DC link and precharge-related faults account for approximately 15–20% of inverter startup failures, making systematic troubleshooting essential for minimizing downtime.

2. Overview of Siemens Masterdrives VC Series

The Siemens Masterdrives VC (Vector Control) series is a modular drive platform designed for applications requiring high dynamic response and accurate torque control.

Typical features include:

- Input voltage: 3-phase 380–480 V AC, 50/60 Hz

- Output: 3-phase 0–480 V, 0–500 Hz

- Power range: From less than 1 kW up to several hundred kW

- DC link voltage: Approximately 1.34 × line voltage

- Control modes:

- V/Hz open loop (fans, pumps)

- Vector control closed loop (hoists, traction, extruders)

The system architecture consists of:

- Control Unit (CU)

- Power Electronics Unit (PEU)

- Optional boards (CB, TB, SCB, TSY, encoder modules)

Integrated protection functions include overload monitoring, temperature estimation, ground fault detection, and extensive fault logging.

The Masterdrives VC series is widely used in cranes, rolling mills, traction systems, conveyors, and test benches where precise dynamic performance is required.

3. Drive Operating Principle

Masterdrives VC uses vector control technology to decouple magnetic flux and torque. The operating sequence includes:

Rectification and Precharging

Incoming AC voltage is rectified into DC. The precharge circuit limits inrush current while charging the DC link capacitors.

DC Link Stabilization

The DC capacitors store energy and smooth voltage ripple. During precharging, the DC voltage must rise above the internal monitoring threshold.

Inversion

IGBT modules generate a PWM output to supply the motor with variable voltage and frequency.

Control Loop

Encoder or analog feedback enables closed-loop speed or torque control.

State Machine

The internal sequence transitions from:

- Ready to power-up

- Precharging

- Ready

- Run

If the DC voltage does not rise fast enough during precharge, the system remains in the precharging state and finally triggers F002.

4. Parameterization and Startup Process

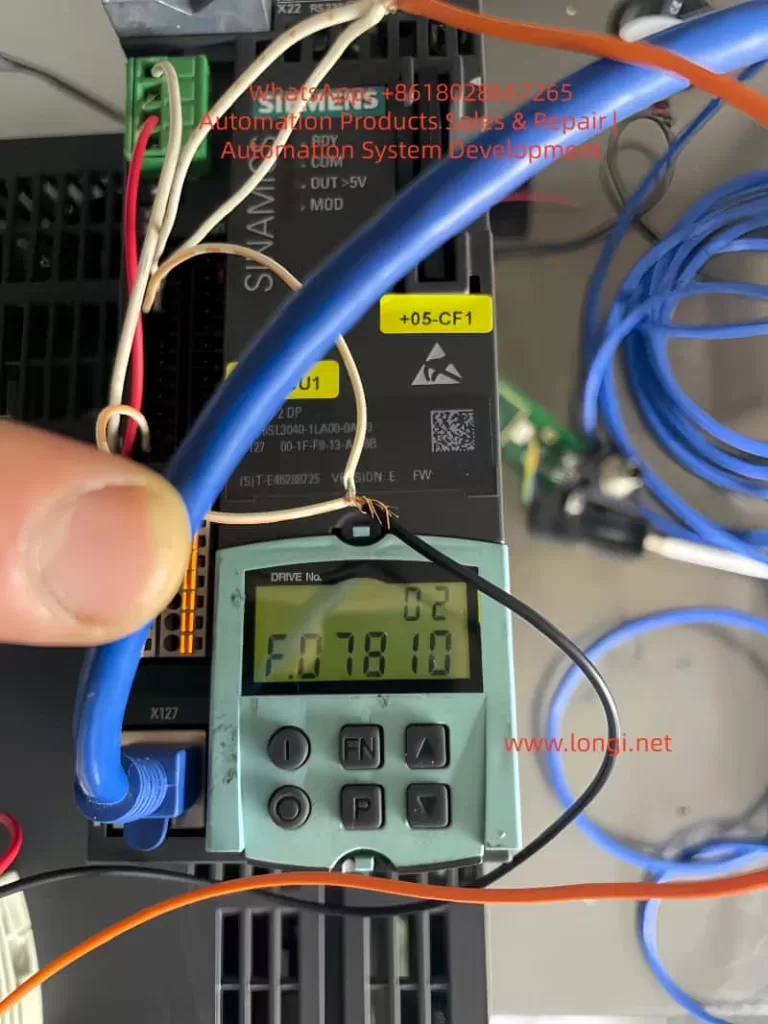

Commissioning is typically performed using the PMU panel, OP1S, or DriveMonitor software.

Important configuration steps include:

- Factory reset:

P052 = 2 - Enter MLFB number:

P070 - Motor data:

P100 – P109 - Automatic motor identification:

P052 = 7 or 8 - Control tuning:

P225 – P229,P253 – P254 - Feedback configuration:

P208,P209 - Setpoint source:

P443 - Contactor control:

- Output:

P612 - Feedback:

P591

- Output:

- Auto restart:

P366,P367

During precharge, parameter P071 (supply voltage) determines the DC voltage reference. Parameter r006 displays actual DC link voltage.

5. Fault Code System

Masterdrives VC uses three-digit fault codes.

- Fxxx: Trip faults (pulse inhibited)

- Axxx: Alarms (drive still running)

Fault memory registers:

r947– fault coder949– fault valuer951– timestamp

F002 belongs to the precharging fault group and is directly linked to the startup state machine.

6. Detailed Explanation of F002 Precharging Fault

Fault definition:

The DC link voltage fails to reach the defined threshold within the monitoring time.

Threshold:

Approximately 80% of (P071 × 1.34)

Typical example:

P071 = 400 V → DC nominal ≈ 536 V → Threshold ≈ 430 V

Fault condition:

If r006 < threshold after approximately 3 seconds during the precharge phase, F002 is triggered.

Typical root causes:

- Incorrect or unstable incoming power

- Main contactor not closing

- Missing contactor feedback

- Failed precharge resistor or board

- DC capacitors degraded

- Wrong hardware configuration

- Long-term storage without capacitor reforming

7. Diagnostic Procedure

A structured approach is recommended:

- Check incoming power

- Measure 3-phase voltage

- Verify P071 matches actual supply

- Monitor DC link voltage

- Observe

r006during startup

- Observe

- Verify contactor operation

- Check P612 output

- Check P591 feedback signal

- Measure coil voltage

- Observe drive states

r001 = 010indicates precharging

- Inspect hardware

- Precharge resistors

- DC bus capacitors

- Wiring and fuses

- Check grounding

- Run

P354ground fault test

- Run

- Analyze fault memory

r947 – r951

- Perform internal test

P052 = 11

8. Corrective Actions

Depending on findings:

- Adjust P071 or correct power supply

- Repair or replace contactor and feedback wiring

- Replace precharge board or resistors

- Reform or replace DC capacitors

- Reinitialize parameters

- Replace defective control or power modules

After repair, clear fault and restart. Monitor DC voltage rise and confirm the drive transitions to “Ready” state.

9. Case Studies

Case 1 – Traction drive in steel plant

F002 occurred intermittently. DC voltage only reached 520 V. Precharge resistor found open-circuit. Replaced precharge board and stabilized power supply. System restored.

Case 2 – Crane slewing system

Main fuse failure damaged precharge resistor. F002 occurred every startup. Replaced resistor and fuse. Verified contactor feedback.

Case 3 – Long-term stored drive

DC capacitors lost forming. Reformed capacitors slowly using external DC supply. Fault cleared.

10. Preventive Maintenance and Best Practices

- Annual inspection of DC link voltage and contactors

- Capacitor reforming after long storage

- Regular parameter backup

- Maintain proper cabinet temperature and humidity

- Use shielded motor cables

- Update firmware where applicable

- Operator training on startup diagnostics

11. Advanced Configuration Considerations

Key parameters related to F002:

| Parameter | Description | Typical Value | Relevance |

|---|---|---|---|

| P071 | Line voltage | 380–480 V | Defines DC threshold |

| P366 | Auto restart | 0–3 | Monitoring behavior |

| P367 | Restart delay | 0–650 s | Precharge timing |

| P612 | Contactor output | 1001 | Enables precharge |

| P591 | Contactor feedback | 1003 | Confirms closure |

| r006 | DC voltage | > threshold | Real-time check |

| r001 | Drive state | 010 = precharge | Fault location |

DriveMonitor software is strongly recommended for trend analysis and documentation.

12. Conclusion

The Siemens Masterdrives VC F002 precharging fault is a critical startup protection mechanism. Although common, it can be resolved efficiently through systematic diagnosis focusing on supply voltage, precharge circuitry, and contactor control.

With proper maintenance and configuration, Masterdrives VC systems remain highly reliable. Applying the methods described in this guide can significantly reduce downtime and extend equipment service life.