Introduction

Variable frequency drives (VFDs) like the ABB ACS580 are vital in industrial automation, offering precise control over motor speed and torque for applications such as pumps, fans, and conveyors. These drives enhance efficiency but can encounter faults that disrupt operations. One common issue is fault code 4310, also known as A4B0, which signals that the power unit module temperature has exceeded safe limits. This article explores the causes, mechanisms, troubleshooting steps, and preventive measures for this fault, providing a comprehensive guide for users and maintenance personnel to ensure reliable operation.

Understanding Fault 4310 (A4B0)

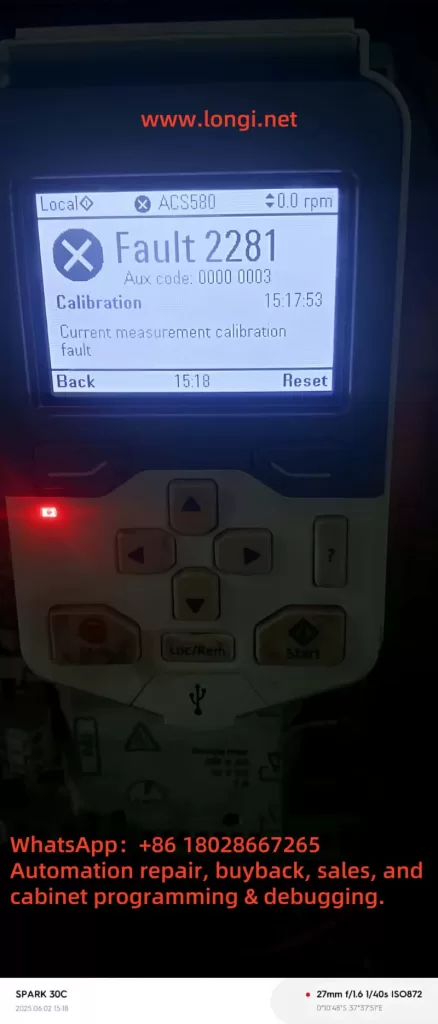

Fault 4310 (A4B0) in the ABB ACS580 indicates that the temperature of the power unit module, which contains insulated gate bipolar transistors (IGBTs) responsible for converting DC to AC for motor control, has become excessively high. IGBTs generate heat during operation due to switching and conduction losses. When the temperature exceeds a safe threshold (typically 90-100°C, depending on the model), the drive triggers this fault to halt operation and protect internal components from thermal damage. The fault code appears on the control panel, often with auxiliary codes indicating specific issues, such as overheating in the U, V, or W phase, or environmental factors.

Causes of Fault 4310 (A4B0)

Several factors can contribute to the power unit module overheating, including:

- High Ambient Temperature: The ACS580 is designed to operate in environments up to 40°C (104°F). If the surrounding temperature exceeds this, the cooling system may struggle to dissipate heat effectively, especially in enclosed or poorly ventilated spaces.

- Insufficient Cooling: The drive relies on cooling fans to draw air over heat sinks attached to the power modules. Fan failures due to worn bearings, electrical issues, or blocked airflow paths (e.g., by debris or improper placement) reduce cooling efficiency.

- Dust Accumulation: In industrial environments, dust and particulate matter can accumulate on heat sinks, acting as an insulator and hindering heat transfer. This reduces the cooling system’s effectiveness.

- Overloading: Operating the drive beyond its rated power capacity causes the IGBTs to generate excessive heat. This can occur if the connected motor or load exceeds the drive’s specifications.

- Incorrect Installation: ABB provides specific installation guidelines, including minimum clearance distances for airflow. Installing the drive in a confined space or near heat-generating equipment can trap heat, leading to overheating.

Mechanism of Fault 4310 (A4B0)

The ACS580 is equipped with temperature sensors that continuously monitor the power unit module’s temperature. These sensors are integrated into the drive’s control system, which compares the measured temperature against a predefined limit. If the temperature exceeds this threshold, the drive activates fault 4310 (A4B0) to stop operation, preventing damage to the IGBTs and other components. The fault may be accompanied by auxiliary codes that pinpoint the issue, such as specific phase overheating (U, V, or W), environmental temperature issues, or internal component failures. This protective mechanism ensures the drive’s longevity and reliability by addressing thermal risks promptly.

Troubleshooting and Solutions

To resolve fault 4310 (A4B0), follow these systematic steps:

- Check Ambient Temperature: Measure the temperature near the drive using a reliable thermometer. Ensure it is within the 0-40°C range specified for the ACS580. If the temperature is too high, improve ventilation by adding fans or air conditioning, or relocate the drive to a cooler area.

- Inspect Cooling Fans: With the drive powered off, check all cooling fans for proper operation. Look for signs of damage, loose connections, or worn bearings. Listen for unusual noises indicating fan issues. Replace faulty fans with ABB-approved components and verify that the fan direction supports proper airflow.

- Clear Airflow Paths: Ensure that air intake and exhaust vents are free from obstructions such as cable bundles, dust filters, or other objects. Remove any covers or panels that restrict airflow and reposition items as needed.

- Clean Heat Sinks: Disconnect the drive from power and use compressed air or a soft brush to remove dust and debris from the heat sinks. Avoid using liquids that could leave residues or damage components. Ensure the heat sinks are clean to maximize heat transfer.

- Verify Load: Compare the drive’s rated power (listed on its nameplate) with the motor’s specifications and the actual load. If the load exceeds the drive’s capacity, consider reducing the load or upgrading to a higher-capacity drive model.

- Review Installation: Consult the ABB ACS580 installation manual to confirm that the drive is mounted correctly. Ensure there is at least 100 mm (4 inches) of clearance on all sides for airflow. Verify that the drive is not exposed to direct sunlight or other heat sources.

- Reset the Drive: After addressing the above issues, reset the drive by cycling power or using the reset button on the control panel. Monitor the drive’s operation to ensure the fault does not recur. Check the event log for any additional diagnostic information.

Troubleshooting Steps Table

| Step | Action | Notes |

|---|---|---|

| Check Ambient Temperature | Measure temperature near the drive | Ensure within 0-40°C; improve ventilation if needed |

| Inspect Cooling Fans | Check for operation, damage, or noise | Replace faulty fans; confirm correct airflow direction |

| Clear Airflow Paths | Remove obstructions from vents | Ensure no cables or debris block intake/exhaust |

| Clean Heat Sinks | Use compressed air or brush to clean | Power off drive; avoid liquids |

| Verify Load | Compare drive and motor ratings | Reduce load or upgrade drive if necessary |

| Review Installation | Check clearance and placement | Ensure 100 mm clearance; avoid heat sources |

| Reset Drive | Cycle power or use reset button | Monitor for fault recurrence |

Preventive Measures

To minimize the risk of fault 4310 (A4B0), implement these preventive strategies:

- Regular Maintenance Schedule: Establish a maintenance routine, inspecting and cleaning the cooling system every 6-12 months, depending on the environment’s dust levels. Regular checks prevent dust buildup and ensure fan reliability.

- Temperature Monitoring: Utilize the ACS580’s built-in temperature monitoring features (accessible via parameters like 04.11-04.13) to track temperature trends. Set alarms to alert personnel if temperatures approach critical levels, enabling early intervention.

- Load Management: Design systems with adequate headroom for peak loads. Avoid operating the drive at or near its maximum capacity for extended periods. Use energy-saving modes or adjust parameters to optimize performance for variable loads.

- Proper Installation Practices: Adhere to ABB’s installation guidelines, ensuring proper mounting, electrical connections, and grounding. Maintain specified clearance distances to support airflow and prevent heat buildup.

- Environmental Control: In harsh environments (e.g., dusty or hot locations), use NEMA-rated enclosures and maintain air filters. In high-temperature settings, consider additional cooling solutions like heat exchangers or air conditioning.

Preventive Measures Table

| Measure | Action | Frequency |

|---|---|---|

| Regular Maintenance | Inspect and clean cooling system | Every 6-12 months |

| Temperature Monitoring | Track temperature trends via parameters | Weekly or monthly |

| Load Management | Ensure load matches drive capacity | During system design |

| Proper Installation | Follow ABB guidelines for mounting | During installation |

| Environmental Control | Use enclosures, filters, or cooling | As needed per environment |

Conclusion

Fault 4310 (A4B0) in the ABB ACS580, indicating excessive power unit module temperature, is a critical issue that demands prompt attention to prevent damage to the drive. By understanding its causes—such as high ambient temperatures, cooling failures, dust accumulation, overloading, or improper installation—users can follow systematic troubleshooting steps to resolve the issue. Preventive measures, including regular maintenance, temperature monitoring, load management, and proper installation, are essential for minimizing the risk of recurrence. Familiarity with the drive’s documentation, such as the user manual and fault tracing guide, and ongoing training for maintenance personnel further enhance operational reliability. By addressing this fault effectively, users can ensure the ACS580 operates efficiently, supporting uninterrupted industrial processes.