I. Introduction

In modern industrial automation, the Human Machine Interface (HMI) plays a critical role in boosting production efficiency and ensuring operational safety. Pro-face, a Japanese brand well-known in the HMI field, has adopted a modular design in its SP series touchscreens: users can freely choose different display sizes and pair them with the appropriate “box modules” to handle complex control tasks. Thanks to this design, the Pro-face SP series is widely used across industries such as machinery manufacturing, electronics assembly, pharmaceuticals, and food processing.

Despite its popularity, many users have questions when disassembling or maintaining an SP series touchscreen. Specifically, they may wonder about the module located on the back that looks like a “power box” or “processor unit.” What function does it serve? If you remove this module, can the display still operate as long as it is powered? This article will take an in-depth look at the Pro-face SP-5B10 (PFXSP5B10) box module—its features and importance, how it interacts with the display module, and whether or not the touchscreen can still function normally once the module is removed.

II. Overview of the Pro-face SP-5B10 Module

1. Module Positioning: The Core Processing Unit of the HMI

The Pro-face SP-5B10 box module (also known as the “enhanced box module” or “Power Box”) is the “brain” of the SP5000 series touchscreen system. It houses the processor, memory, and various industrial communication interfaces. Unlike a traditional, single-unit HMI device, Pro-face introduced a modular approach in the SP series by separating the display section and the processing section, referred to as the display module and the box module, respectively. As the box module, SP-5B10 is in charge of running control logic, storing project data, connecting devices via different networks, and overseeing the overall operation of the system.

2. The “Brain” for Running Business Logic and Display Screens

In practical applications, an HMI often needs to run custom programs for production lines, equipment, or processes—such as displaying workflows, monitoring real-time data, and sending or receiving control commands. These configured screens and logic programs are developed via software like GP-Pro EX and are downloaded to the box module. The SP-5B10 provides ample processing power and memory to execute these screen logics, data collection tasks, and alarm management. It then transmits the resulting display data to the display module. Essentially, without the box module’s processing and control, the HMI’s “intelligence” does not exist, and the touchscreen would be reduced to a blank display panel.

3. Data and System Software Storage

The SP-5B10 box module integrates storage features, including an SD card slot, internal flash memory, and backup battery. In more detail:

- System Storage: Contains the HMI’s system firmware, operating system, and basic drivers needed for startup.

- Project Data Storage: Stores project files, alarm information, recipe data, etc., that are downloaded from development software such as GP-Pro EX. This approach allows easy maintenance; for instance, if the display module needs replacing, simply removing and reattaching the box module or swapping the storage card can restore the entire application.

- Alarm and Historical Records: Many industrial environments require the recording of alarm data and operational logs—sometimes for weeks or months. The SP-5B10’s internal flash memory or SD card meets these demands.

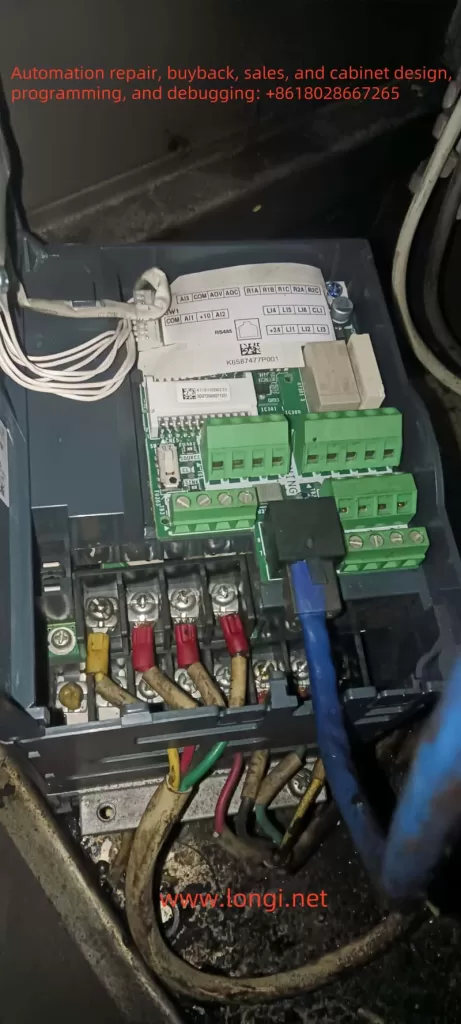

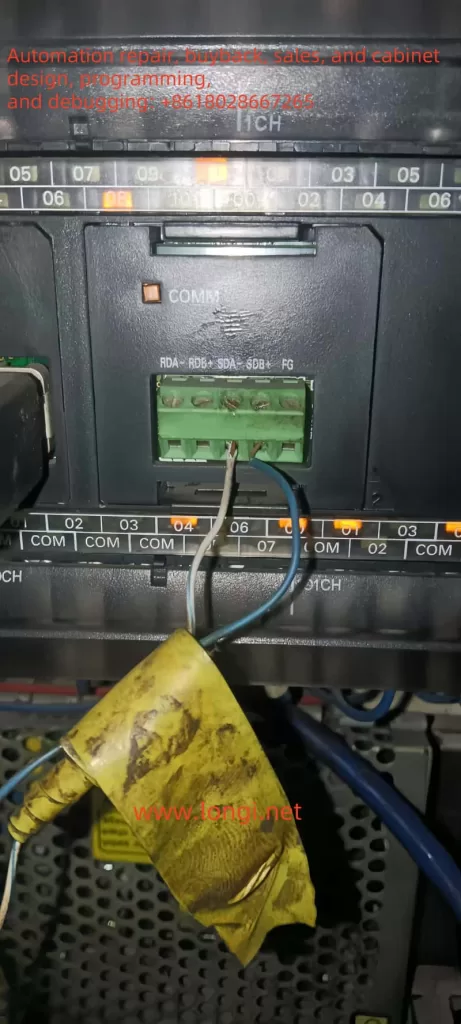

4. The Central Hub for Multiple Industrial Communication Interfaces

In industrial settings, an HMI commonly exchanges data with PLCs, inverters, sensors, or upper-level management systems, making diverse interfaces and protocols critical. The SP-5B10 often includes:

- Ethernet Ports: Typically at least one or two RJ-45 ports supporting 10/100/1000 Mbps to connect PLCs, SCADA, or MES systems.

- Serial Interfaces (COM Ports): RS-232C, RS-422/485, etc., for older PLCs and instruments still widely used.

- USB Host/Device Ports: For connecting USB peripherals such as flash drives or barcode scanners, as well as for direct communication or program downloads from a PC.

- Expansion Bus: Some box modules allow additional interface cards (e.g., fieldbus expansions, field I/O boards) to suit a variety of automation scenarios.

As the conduit for all external signals and data, the SP-5B10 processes information before passing it on to the display module, allowing seamless “field–HMI–network” connectivity.

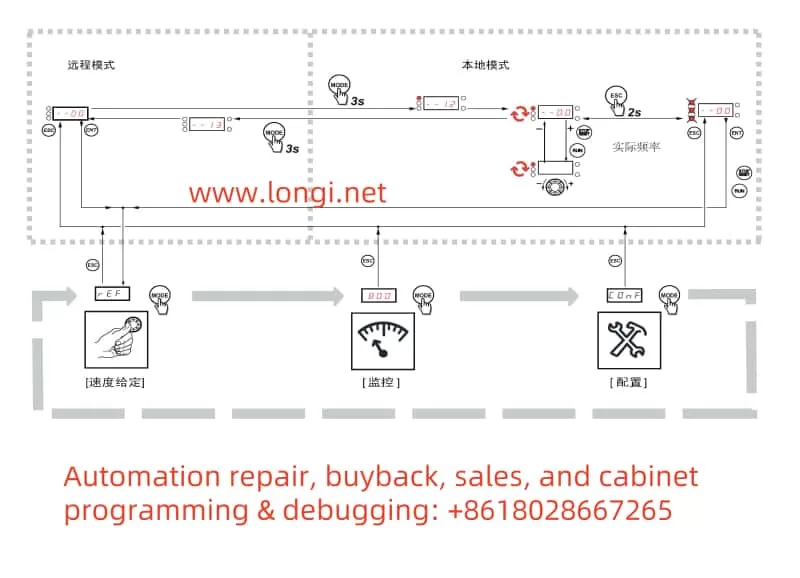

III. How the SP-5B10 Works with the Display Module

1. Physical Connection: A Rear Plug-in Connector

In the Pro-face SP5000 series, the box module and display module link up via a specialized connector on the display’s rear side. The box module securely latches onto the display module through a rail or clip mechanism:

- Power Supply: The display module connects to external power (e.g., 24 V DC) and converts it internally to power the box module, which does not require its own power input.

- Signal Transmission: The connector transmits video signals while also carrying touch input signals and other data between the processor and display.

This modular concept makes it easy for users to replace or upgrade components. For example, if you want to switch to a larger display but keep the same box module, simply remove the original display and connect the SP-5B10 to a new, larger SP series display. Likewise, if you need higher processing performance, you can upgrade only the box module without having to swap out the entire display screen.

2. Logical Coordination: Clear Division of Labor, Integrated Operation

The SP-5B10 handles core computing, communications, and data storage, while the display module is responsible for UI presentation and touch sensing. Their cooperation can be summarized as:

- Screen Data Transmission: The SP-5B10 runs the screen logic and sends the display content to the display module, which then renders and displays it.

- Touch Feedback: When an operator touches a button or drags an object on the screen, the display module detects the action and relays it back to the box module for processing, which either responds or carries out related control commands.

- System Health Management: If the box module detects high temperature or an internal fault, it can alert the display module to show warnings or shut off the backlight, ensuring safe operation of the entire system.

IV. What Happens if You Remove the SP-5B10?

Many wonder whether the front display panel can still function if the box module is taken out. The short answer is no. The SP-5B10 is not a simple add-on accessory; it is the “brain” and “heart” of the entire HMI system. Once it is removed, the display module loses its processor, memory, and communication interfaces, which means it becomes non-functional. Specifically:

- No Display

Without the display data provided by the SP-5B10, the screen may only have power for the backlight (if at all) but will show no graphics or text. All HMI screens are generated by the box module, so with it removed, there is no output signal for the display panel. - No Touch Operation

Since no box module is present to read and process touch coordinates, any touch input is rendered meaningless. Typically, the screen’s coordinate signals must be sent to and interpreted by higher-level software or the OS, which runs on the SP-5B10. - Loss of Data Collection and Communication

The box module provides interfaces like serial ports, Ethernet, and USB. Removing it also removes these interfaces, and thus the touchscreen can no longer communicate with PLCs, sensors, or PCs. Effectively, all monitoring and control functions cease. - Loss of System and Project Data

The SP-5B10 stores screen projects, recipes, alarm history, and more on an SD card or in internal memory. Removing the module effectively takes away all critical data needed for system operation. The display module itself usually does not retain these files and cannot independently load the application.

Hence, removing the SP-5B10 renders the Pro-face touchscreen incapable of displaying or interacting with any functionality. The system will only resume normal operation once the box module (or a compatible alternative) is reattached and powered up.

V. Conclusion and Recommendations

In summary, the Pro-face SP-5B10 box module is an irreplaceable core component of the SP series touchscreen. It not only handles screen display and touch input processing, but also provides the storage space, communication interfaces, and expansion capabilities vital for complete HMI functionality. For engineers and maintenance personnel who rely on Pro-face HMIs for field device monitoring, data collection, and process visualization, ensuring that the box module and display module remain properly connected and functioning is crucial.

If you need a functioning display, you cannot rely solely on the screen hardware. During maintenance, if you must remove the box module, always do so with the power off and take precautions to protect the storage card and the module from static or physical damage. Bear in mind that once the SP-5B10 is removed, the touchscreen loses its central processing capability and will not operate; only by reinstalling the compatible box module and powering the system can normal functions be restored.

In essence, the SP-5B10 module is like the processor and storage system in a smartphone—without it, even the best screen is just inert “glass.” Removing it inevitably leads to loss of the original interface, disabling any touch inputs or data communications. Therefore, to ensure stable, continuous operation of Pro-face HMIs, the SP-5B10 and display module must remain tightly integrated so that the system can take full advantage of the module’s high-speed processing and multi-interface communication features, enabling better equipment monitoring and process management on the industrial floor.