Company Introduction

Longi Electromechanical has over 20 years of history, specializing in the field of industrial automation. With extensive experience in PLC (Programmable Logic Controller) applications, programming, unlocking, and repairs, our company boasts strong technical capabilities. Our experienced engineers and expert team efficiently and swiftly solve various issues encountered by customers in PLC applications.

Service Scope

We provide comprehensive PLC-related services covering major brands and applications across various industries.

Common PLC Brands and Models

- Siemens: S7-200, S7-300, S7-400, S7-1200, S7-1500

- Mitsubishi: FX Series, Q Series, L Series

- Omron: CJ Series, CP Series, CS Series

- Schneider: Modicon Series, M221, M241, M251

- Delta: DVP Series, AS Series

- Rockwell (AB): MicroLogix Series, CompactLogix Series, ControlLogix Series

- Fuji: MICREX Series, SPH Series

- Panasonic: FP Series

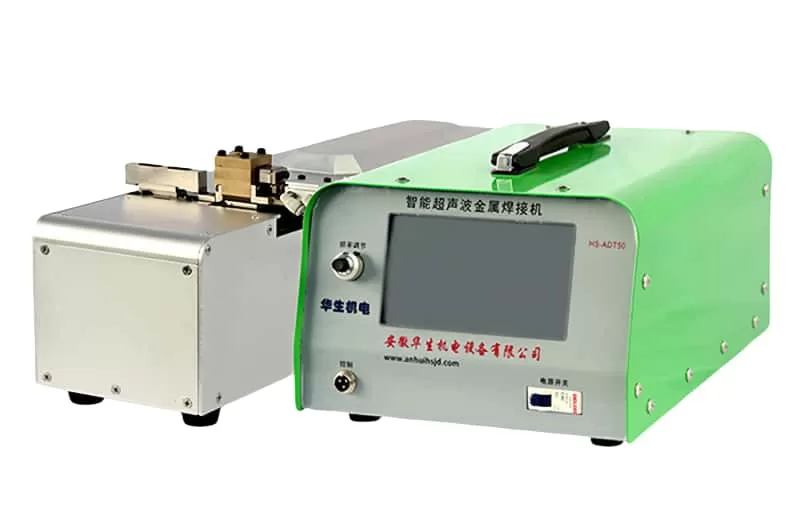

Industry Applications

- Packaging Machinery

- Printing Machinery

- Injection Molding Equipment

- CNC Machines

- Chemical Processing Equipment

- Food Processing Equipment

- Wastewater Treatment Automation Systems

- Constant Pressure Water Supply Systems

- Automated Production Lines

Core Services

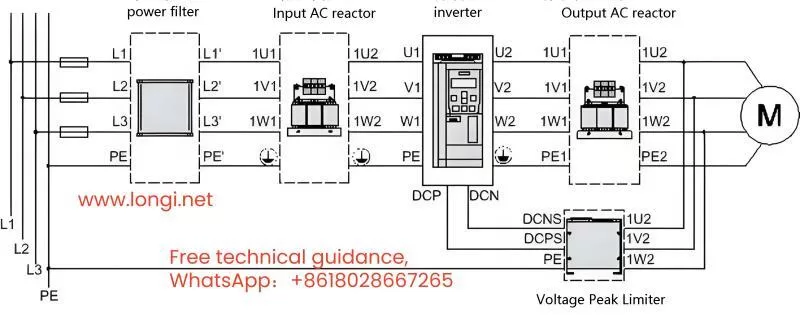

1. PLC Programming Services

Our engineers have extensive programming experience and can customize various automation control system solutions according to customer needs, offering comprehensive services from requirement analysis, system design, program development, to on-site commissioning.

- Automation system design

- New system development

- Upgrading and retrofitting old systems

- Program optimization

- On-site commissioning and technical support

2. PLC Unlocking Services

Longi Electromechanical specializes in unlocking various PLC brands, quickly resolving issues caused by forgotten PLC passwords or system protection.

- PLC password cracking and recovery

- PLC program backup and recovery

- Security unlocking technical consultation for various PLC brands

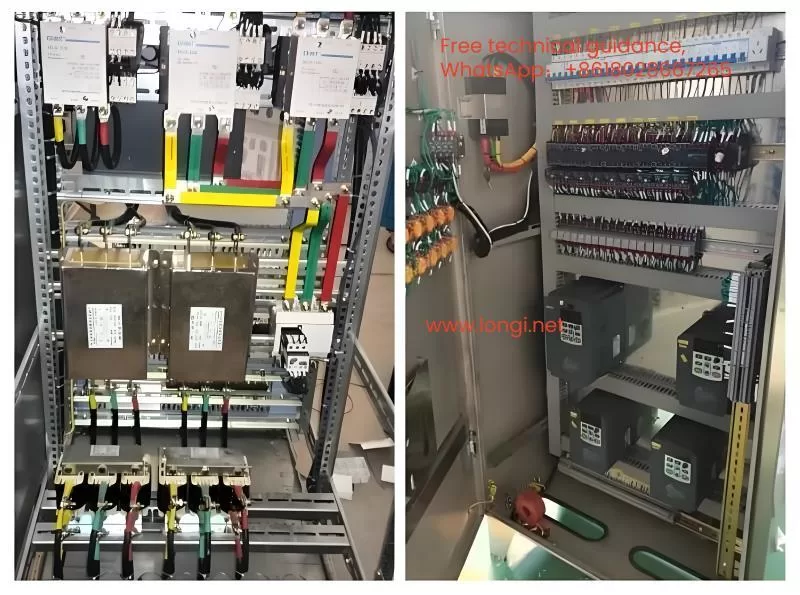

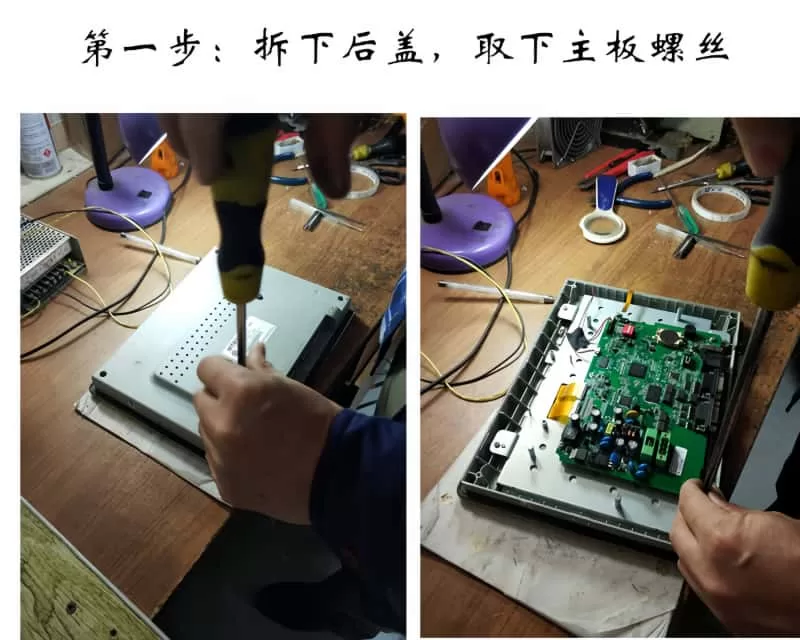

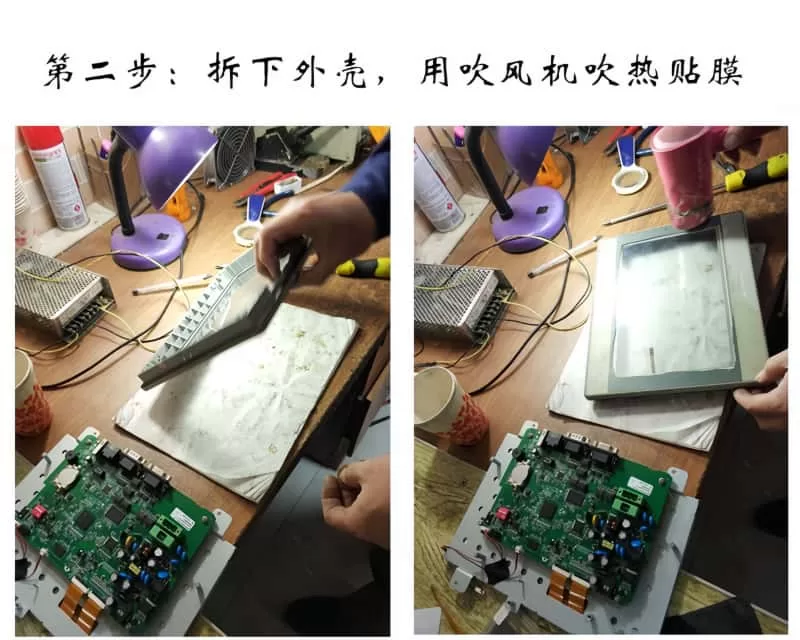

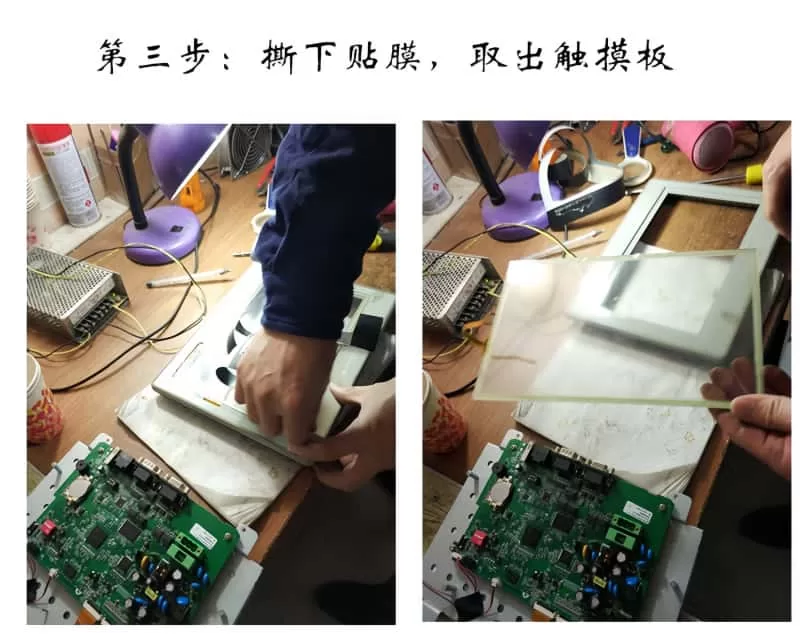

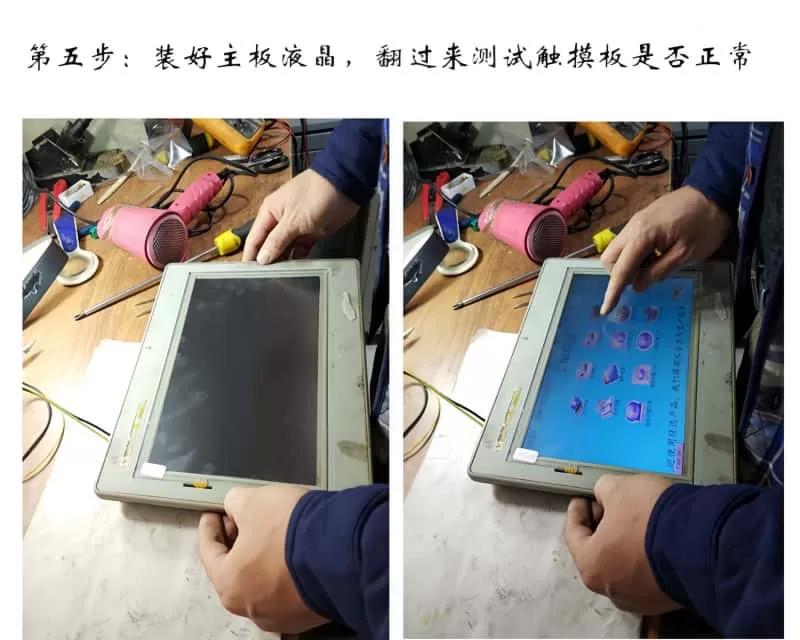

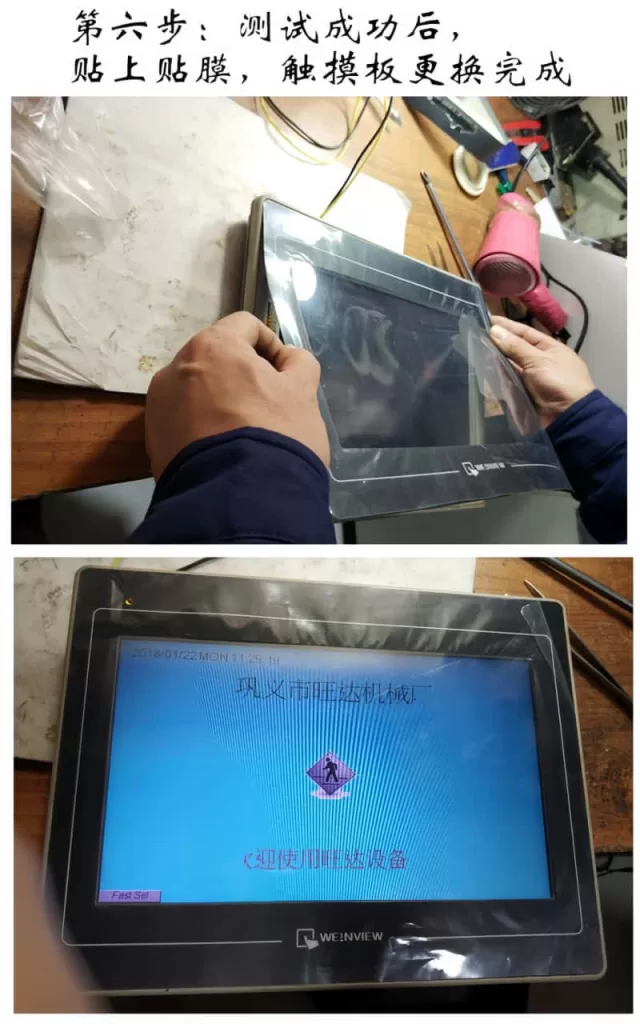

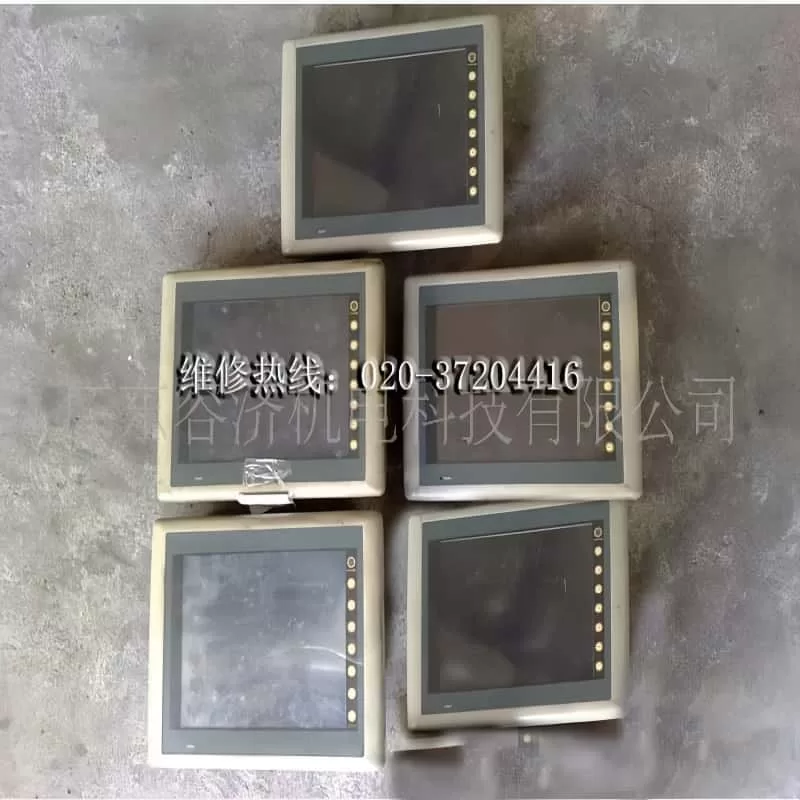

3. PLC Repair Services

We provide rapid diagnostic and repair services for various PLC brands, including both hardware and software repairs.

- Repair of PLC mainboards and expansion modules

- PLC communication fault troubleshooting

- Diagnostic and repair of I/O modules

- On-site emergency repairs and remote technical support

Why Choose Longi Electromechanical?

- Over 20 years of experience in the PLC industry

- Professional technical team and senior engineers

- Rapid response to customer needs

- Reliable technical support and after-sales service

- Extensive experience covering various brands and industry applications

Choose Longi Electromechanical for professionalism and peace of mind!

WhatSapp:+8618028667265; Zalo:+8613922254854