I. Product Overview and Technical Background

The Reichert AR360 Auto Refractor, developed by Reichert Ophthalmic Instruments (a subsidiary of Leica Microsystems), represents a cutting-edge electronic refraction device that embodies the technological advancements of the early 21st century in automated optometry. This device incorporates innovative image processing technology and an automatic alignment system, revolutionizing the traditional optometry process that previously required manual adjustments of control rods and chin rests.

The core technological advantage of the AR360 lies in its “hands-free” automatic alignment system. When a patient focuses on a fixed target and rests their forehead against the forehead support, the device automatically identifies the eye position and aligns with the corneal vertex. This breakthrough design not only enhances measurement efficiency (with a single measurement taking only a few seconds) but also significantly improves patient comfort, making it particularly suitable for children, the elderly, and patients with special needs.

As a professional-grade ophthalmic diagnostic device, the AR360 offers a comprehensive measurement range:

- Sphere: -18.00D to +18.00D (adjustable step sizes of 0.01D/0.12D/0.25D)

- Cylinder: 0 to 10.00D

- Axis: 0-180 degrees

It caters to the full spectrum of refractive error detection, from mild to severe cases.

II. Device Composition and Functional Module Analysis

2.1 Hardware System Architecture

The AR360 features a modular design with the following core components:

Optical Measurement System:

- Optical path comprising an infrared light source and imaging sensor

- Built-in self-calibration program (automatically executed upon power-on and after each measurement)

- Patient observation window with a diameter of 45mm, featuring a built-in green fixation target

Mechanical Positioning System:

- Translating headrest assembly (integrated L/R detector)

- Automatic alignment mechanism (accuracy ±0.1mm)

- Transport locking device (protects internal precision components)

Electronic Control System:

- Main control board (with ESD electrostatic protection circuitry)

- PC card upgrade slot (supports remote software updates)

- RS-232C communication interface (adjustable baud rate from 2400 to 19200)

Human-Machine Interface:

- 5.6-inch LCD operation screen (adjustable contrast)

- 6-key membrane control panel

- Thermal printer (printing speed of 2 lines per second)

2.2 Innovative Functional Features

Compared to contemporary competitors, the AR360 boasts several technological innovations:

- Smart Measurement Modes: Supports single measurement, 3-average, and 5-average modes to effectively reduce random errors.

- Vertex Distance Compensation: Offers six preset values (0.0/12.0/13.5/13.75/15.0/16.5mm) to accommodate different frame types.

- Data Visualization Output: Capable of printing six types of refractive graphs (including emmetropia, myopia, hyperopia, mixed astigmatism, etc.).

- Multilingual Support: Built-in with six operational interface languages, including English, French, and German.

III. Comprehensive Device Operation Guide

3.1 Initial Setup and Calibration

Unboxing Procedure:

- Remove the accessory tray (containing power cord, dust cover, printing paper, etc.)

- Release the transport lock (using the provided screwdriver, turn counterclockwise 6 times)

- Connect to power (note voltage specifications: 110V/230V)

- Perform power-on self-test (approximately 30 seconds)

Basic Parameter Configuration:

Through the MODE→SETUP menu, configure:

- Refractive power step size (0.01/0.12/0.25D)

- Cylinder display format (negative/positive/mixed cylinder)

- Automatic measurement switch (recommended to enable)

- Sleep time (auto-hibernation after 5-90 minutes of inactivity)

3.2 Standard Measurement Procedure

Step-by-Step Instructions:

Patient Preparation:

- Adjust seat height to ensure the patient is at eye level with the device.

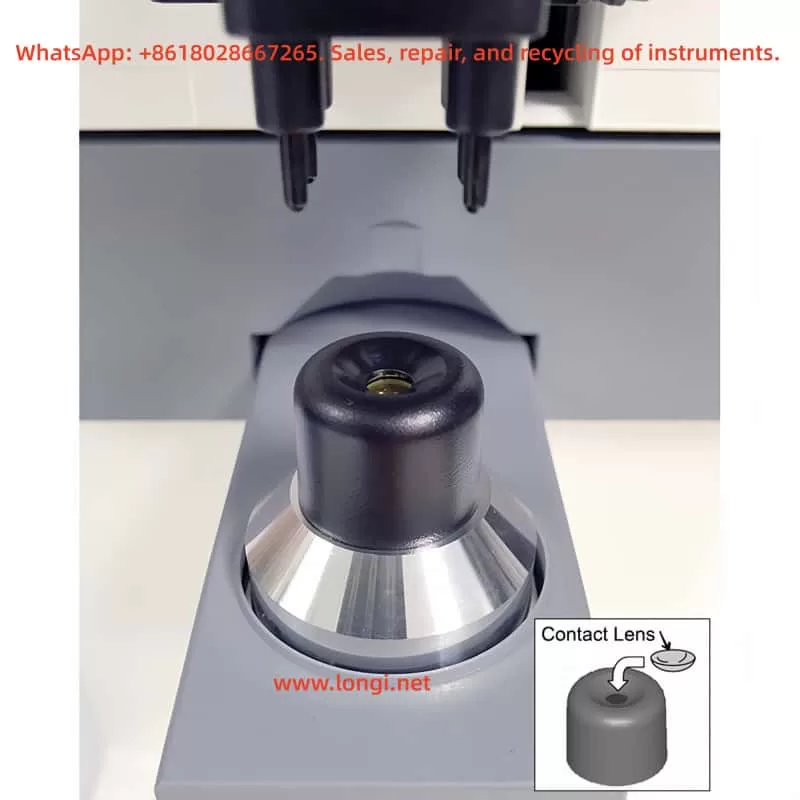

- Instruct the patient to remove glasses/contact lenses.

- Explain the fixation target observation instructions.

Right Eye Measurement:

- Slide the headrest to the right position.

- Guide the patient to press their forehead firmly against the forehead support.

- The system automatically completes alignment and measurement (approximately 3-5 seconds).

- A “beep” sound indicates measurement completion.

Left Eye Measurement:

- Slide the headrest to the left position and repeat the procedure.

- Data is automatically associated and stored with the right eye measurement.

Data Management:

- Use the REVIEW menu to view detailed data.

- Press the PRINT key to output a report (supports图文混合 printing, i.e., a combination of graphics and text).

- Press CLEAR DATA to erase current measurement values.

3.3 Handling Special Scenarios

Common Problem Solutions:

Low Confidence Readings: May result from patient blinking or movement. Suggestions:

- Have the patient blink fully to moisten the cornea.

- Use tape to temporarily lift a drooping eyelid.

- Adjust head position to keep eyelashes out of the optical path.

Persistent Alignment Failures:

- Check the cleanliness of the observation window.

- Verify ambient lighting (avoid direct strong light).

- Restart the device to reset the system.

IV. Clinical Data Interpretation and Quality Control

4.1 Measurement Data Analysis

A typical printed report includes:

[Ref] Vertex = 13.75 mmSph Cyl Ax-2.25 -1.50 10-2.25 -1.50 10-2.25 -1.50 10Avg -2.25 -1.50 10Parameter Explanation:

- Sph (Sphere): Negative values indicate myopia; positive values indicate hyperopia.

- Cyl (Cylinder): Represents astigmatism power (axis determined by the Ax value).

- Vertex Distance: A critical parameter affecting the effective power of the lens.

4.2 Device Accuracy Verification

The AR360 ensures data reliability through a “triple verification mechanism”:

- Hardware-Level: Automatic optical calibration after each measurement.

- Algorithm-Level: Exclusion of outliers (automatically flags values with a standard deviation >0.5D).

- Operational-Level: Support for multiple measurement averaging modes.

Clinical verification data indicates:

- Sphere Repeatability: ±0.12D (95% confidence interval)

- Cylinder Axis Repeatability: ±5 degrees

Meets ISO-9001 medical device certification requirements.

V. Maintenance and Troubleshooting

5.1 Routine Maintenance Protocol

Periodic Maintenance Tasks:

- Daily: Disinfect the forehead support with 70% alcohol.

- Weekly: Clean the observation window with dedicated lens paper.

- Monthly: Lubricate mechanical tracks with silicone-based lubricant.

- Quarterly: Optical path calibration (requires professional service).

Consumable Replacement:

- Printing Paper (Model 12441): Standard roll prints approximately 300 times.

- Fuse Specifications:

- 110V model: T 0.63AL 250V

- 230V model: T 0.315AL 250V

5.2 Fault Code Handling

Common Alerts and Solutions:

| Code | Phenomenon | Solution |

|---|---|---|

| E01 | Printer jam | Reload paper according to door diagram |

| E05 | Voltage abnormality | Check power adapter connection |

| E12 | Calibration failure | Perform manual calibration procedure |

| E20 | Communication error | Restart device or replace RS232 cable |

For unresolved faults, contact the authorized service center. Avoid disassembling the device yourself to prevent voiding the warranty.

VI. Technological Expansion and Clinical Applications

6.1 Comparison with Similar Products

Compared to traditional refraction devices, the AR360 offers significant advantages:

- Efficiency Improvement: Reduces single-eye measurement time from 30 seconds to 5 seconds.

- Simplified Operation: Reduces manual adjustment steps by 75%.

- Data Consistency: Eliminates manual interpretation discrepancies (CV value <2%).

6.2 Clinical Value Proposition

- Mass Screening: Rapid detection in schools, communities, etc.

- Preoperative Assessment: Provides baseline data for refractive surgeries.

- Progress Tracking: Establishes long-term refractive development archives.

- Lens Fitting Guidance: Precisely measures vertex distance for frame adaptation.

VII. Development Prospects and Technological Evolution

Although the AR360 already boasts advanced performance, future advancements can be anticipated:

- Bluetooth/WiFi wireless data transmission

- Integrated corneal topography measurement

- AI-assisted refractive diagnosis algorithms

- Cloud platform data management

As technology progresses, automated refraction devices will evolve toward being “more intelligent, more integrated, and more convenient,” with the AR360’s design philosophy continuing to influence the development of next-generation products.

This guide provides a comprehensive analysis of the technical principles, operational methods, and clinical value of the Reichert AR360 Auto Refractor. It aims to help users fully leverage the device’s capabilities and deliver more precise vision health services to patients. Regular participation in manufacturer-organized training sessions (at least once a year) is recommended to stay updated on the latest feature enhancements and best practice protocols.