I. Module Debugging and Connection

The debugging and connection of the WTW Trescon OA110 NH4-N Ammonia Nitrogen Analysis Module are fundamental to ensure its normal operation. The debugging process includes checking the product delivery list, expanding the analysis module if necessary, connecting the module to the host, and performing initial debugging.

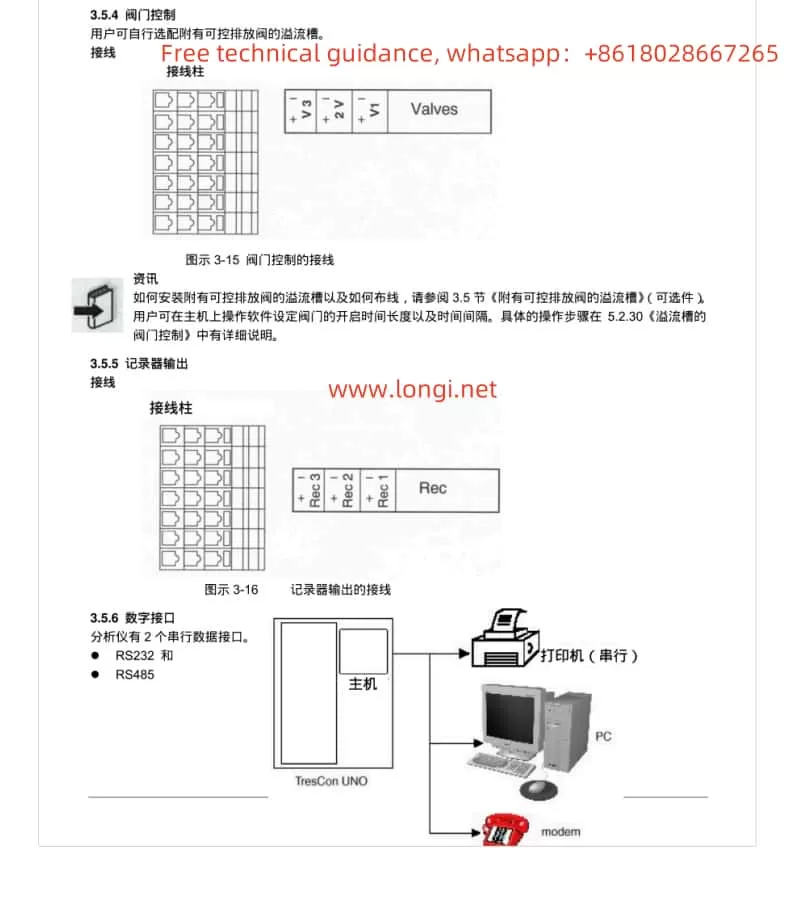

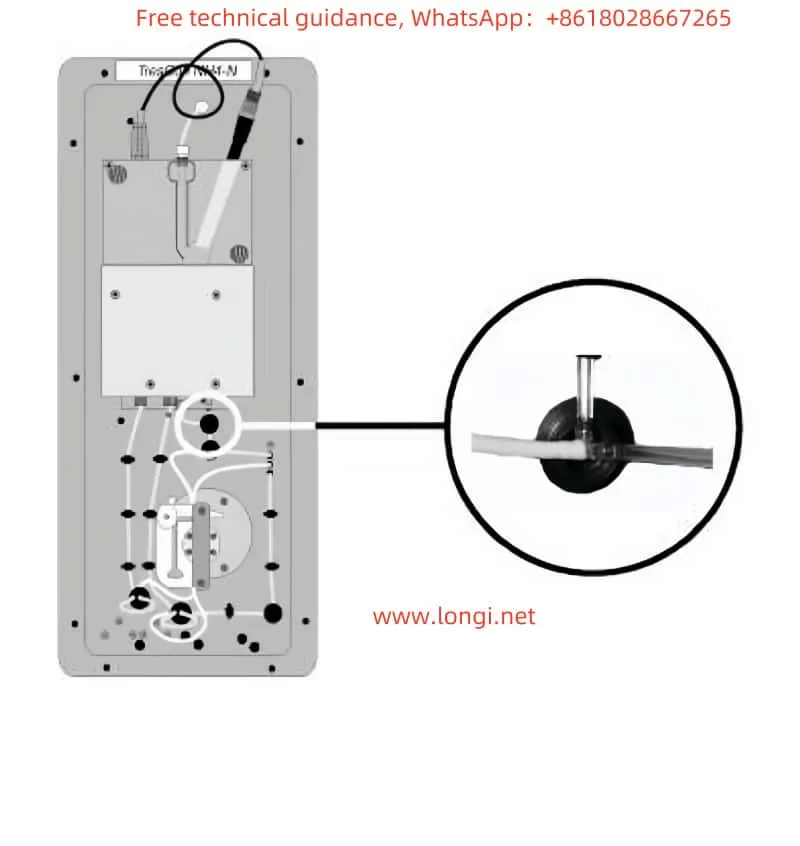

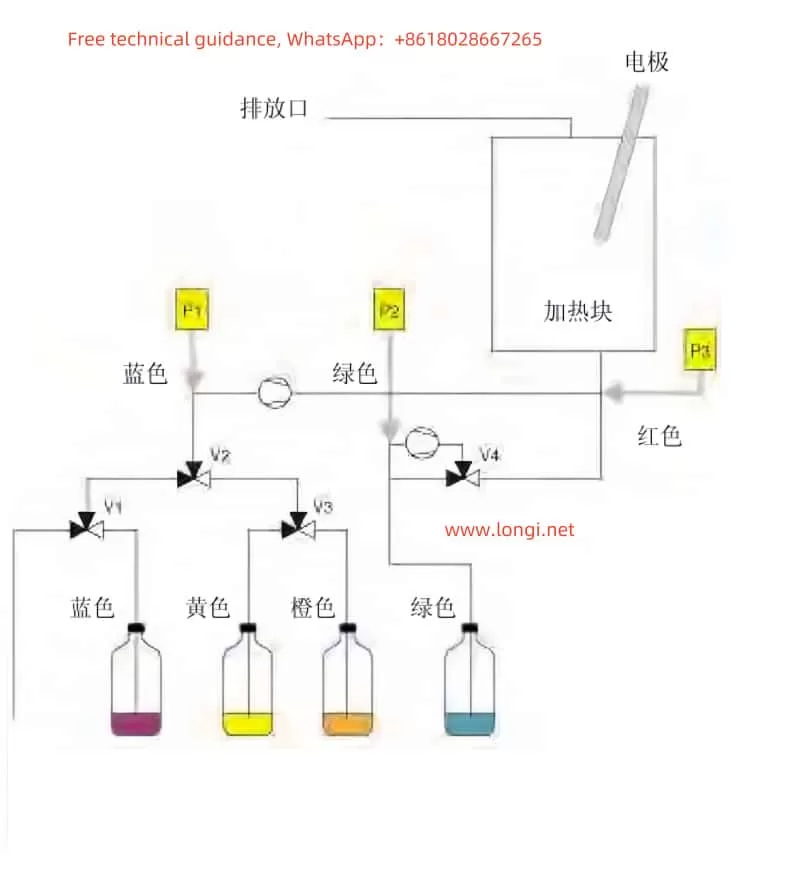

First, users need to verify the product delivery list to ensure that all accessories such as the analysis module, electrodes, tubing, overflow tank, etc., are complete. Next, depending on requirements, users may decide to expand the analysis module. During expansion, it is necessary to install the permeate fluid sampling device and prepare the corresponding reagents. When connecting the analysis module, users need to insert the module’s plug into the corresponding power socket, connect the discharge conduit and ventilation pipe, and install the electrode. Before electrode installation, preprocessing is required, including cleaning the electrode, adding electrolyte, and other steps.

During the initial debugging phase, users need to turn on the power supply, wait for the module to preheat, select the test mode, and perform initial settings such as filling the tubing through the Service menu.

II. Parameter Settings

Parameter settings are crucial for the precise operation of the analysis module. Users can activate various parameter options through the main menu for viewing or modification. Key parameters include calibration data, maintenance, AutoCal (automatic calibration), AutoClean (automatic cleaning), display format, attenuation, interval program, AutoAdapt (automatic adaptation), test interval, and dilution factor. When setting parameters, users need to enter a PIN code to confirm changes, and changes to some important parameters will cause the module to enter stop mode.

III. Module Operation

Module operation includes testing, calibration, displaying calibration data, viewing/changing parameters, etc. Testing can be conducted in continuous or intermittent modes, which can be selected in the interval program menu. The calibration process is automatically completed by the AutoCal system, and users can manually initiate it or set the automatic calibration interval. When displaying calibration data, the module will show the detailed parameters of the last calibration. Users can also view or change various parameter settings through the corresponding menus.

IV. Maintenance

Regular maintenance is crucial to ensure the long-term stable operation of the analysis module. Maintenance includes initiating the AutoClean program, filling tubing, replenishing cleaning solution, replacing silicone tubing, replacing membranes/electrodes, etc. The AutoClean program can automatically clean the system, and users can also manually initiate it. When filling tubing, specific reagents and cleaning solutions need to be used following the step-by-step operation. When replenishing cleaning solution, standard solutions, and reagents, users need to ensure that the containers are connected and filled with the corresponding liquids.

When replacing silicone tubing, users need to first empty the system, then replace or move the silicone tubing, and refill the tubing. When replacing membranes/electrodes, users need to first disconnect the electrode, replace the new membrane or electrode, reconnect it, and recalibrate. In addition, users also need to regularly inspect and replace wear parts such as T-pieces.

V. Error Messages and Troubleshooting

During operation, the analysis module may encounter various error messages, such as reagent blockage, reagent depletion, calibration failure, etc. The module will display error messages on the screen and automatically enter stop mode. Users need to take corresponding measures based on the error message prompts, such as checking if the tubing is twisted, replacing reagent bottles, recalibrating, etc. If the error message cannot be resolved, users can contact the WTW customer service department for assistance.

For example, when the screen displays “Reagent Blockage,” users need to first check if the tubing is twisted or pressed by other objects. If the problem persists, the connecting tubing needs to be replaced. If “Calibration Failure” is displayed, users need to check the electrode status and replace the electrode or membrane if necessary, then recalibrate.

In summary, the WTW Trescon OA110 NH4-N Ammonia Nitrogen Analysis Module manual provides users with detailed guides for debugging, connection, parameter setting, operation, maintenance, and error handling. Users need to carefully read and follow the instructions in the manual to ensure the normal operation of the analysis module and the accuracy of test results.