I. Functional Requirements Analysis of the Washing Machine

The washing machine is primarily used for efficient cleaning of various workpieces. Its core functional requirements include:

- Washing Pump Drive: A high-power motor is required to drive a high-pressure water pump for strong water jetting.

- Conveyor Belt Control: Drive the conveyor belt to achieve continuous workpiece transportation.

- Rotary Brush Control: Drive the rotary brush to perform mechanical scrubbing on the workpiece surface.

- Air-Drying System: Drive the fan to quickly dry the cleaned workpieces.

- Status Monitoring and Protection: Real-time monitoring of motor operation status is required, with overload, overvoltage, and other protection functions.

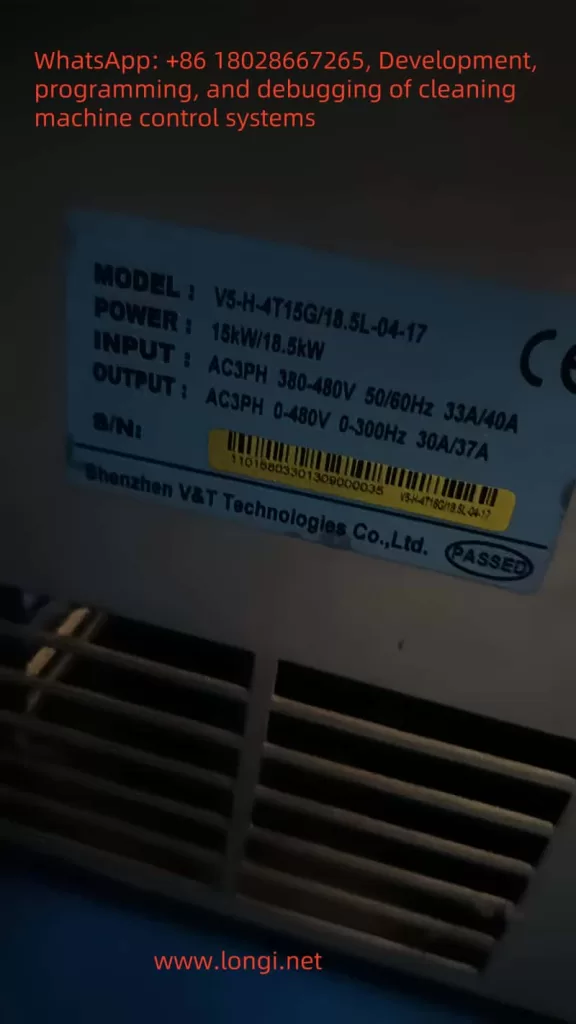

II. V5-H Inverter Selection and Configuration

Based on the power requirements of each functional module of the washing machine, the following V5-H inverter models are selected:

| Functional Module | Motor Type | Power Range | Inverter Model |

|---|---|---|---|

| Washing Pump | Three-phase asynchronous motor | 7.5-11kW | V5-H-11K |

| Conveyor Belt | Three-phase asynchronous motor | 1.5-2.2kW | V5-H-2.2K |

| Rotary Brush | Three-phase asynchronous motor | 2.2-3.7kW | V5-H-3.7K |

| Air-Drying System | Three-phase asynchronous motor | 1.5-2.2kW | V5-H-2.2K |

III. Control Circuit Design

1. Main Circuit Wiring

- Washing Pump Motor:

- Connect the inverter output terminals (U/T1, V/T2, W/T3) to the washing pump motor.

- Connect the braking unit DC output terminal (Ө) to the braking resistor (for rapid shutdown).

- Conveyor Belt Motor:

- Connect the inverter output terminals (U/T1, V/T2, W/T3) to the conveyor belt motor.

- Rotary Brush Motor:

- Connect the inverter output terminals (U/T1, V/T2, W/T3) to the rotary brush motor.

- Air-Drying System Motor:

- Connect the inverter output terminals (U/T1, V/T2, W/T3) to the fan motor.

2. Control Circuit Wiring

- Start/Stop Control:

- Connect the PLC output points to the inverter multi-function input terminals (X1-X7) to achieve remote start/stop.

- Speed Regulation:

- Connect the PLC analog output (0-10V) to the inverter analog input terminal (AI1) to achieve stepless speed regulation.

- Status Feedback:

- Connect the inverter multi-function output terminals (Y1, Y2/DO) to the PLC input points to feedback operation status.

- Fault Protection:

- Connect the inverter fault output terminal to the PLC input point to achieve fault alarming.

- Wiring Diagram:

- PLC output points (Q0.0-Q0.3) → Inverter multi-function input terminals (X1-X7)

- PLC analog output (AQ0.0) → Inverter analog input terminal (AI1)

- Inverter multi-function output terminals (Y1, Y2/DO) → PLC input points (I0.0-I0.1)

- Inverter fault output terminal → PLC input point (I0.2)

IV. Parameter Setting and Optimization

1. Basic Parameter Setting

| Parameter Group | Parameter Name | Setting Value/Range | Description |

|---|---|---|---|

| P0.03 | Control Mode Selection | 1 (Vector Control 1) | Suitable for heavy-duty applications such as washing pumps |

| P0.04 | Frequency Command Method | 1 (AI1 Voltage Command) | Regulate speed through PLC analog output |

| P0.05 | Maximum Operating Frequency | 50Hz | Set according to motor rated frequency |

| P0.08 | Acceleration Time | 5s | Adjust according to load characteristics |

| P0.09 | Deceleration Time | 5s | Adjust according to load characteristics |

2. Advanced Parameter Setting

| Parameter Group | Parameter Name | Setting Value/Range | Description |

|---|---|---|---|

| P8.00 | PID Control Selection | 1 (Enable PID) | Used for closed-loop control of temperature, pressure, etc. |

| P8.01 | Proportional Gain | 2.0 | Adjust according to system response |

| P8.02 | Integral Time | 10s | Adjust according to system stability |

| P8.03 | Derivative Time | 0.1s | Adjust according to system damping |

| P5.01 | Multi-function Input Terminal X1 | 15 (Forward Start) | Define terminal function |

| P5.02 | Multi-function Input Terminal X2 | 16 (Reverse Start) | Define terminal function |

| P7.01 | Multi-function Output Terminal Y1 | 32 (Running) | Define output status |

| P7.02 | Multi-function Output Terminal Y2 | 33 (Fault Output) | Define fault output |

3. Motor Parameter Auto-Tuning

- Set P9.15=1 to activate the motor parameter auto-tuning function.

- Input rated voltage, current, speed, and other parameters according to the motor nameplate.

- Optimize vector control performance after auto-tuning is complete.

V. Collaborative Control of PLC and Inverter

1. PLC Selection

- Model: Siemens S7-1200 CPU 1214C DC/DC/DC

- Features:

- 14 digital input points, 10 digital output points.

- 2 analog input channels, 1 analog output channel.

- Supports Modbus RTU communication protocol.

2. Control Program Logic

- Washing Pump Control:

- Regulate inverter output frequency through PID algorithm based on pressure sensor feedback.

- Achieve constant pressure water supply to improve washing efficiency.

- Conveyor Belt Control:

- Achieve precise positioning through pulse encoder feedback of position information.

- Automatically adjust conveyor belt speed according to workpiece size.

- Rotary Brush Control:

- Control rotary brush start/stop through a timer to achieve intermittent scrubbing.

- Adjust rotary brush speed according to workpiece material.

- Air-Drying System Control:

- Automatically adjust fan speed according to ambient temperature.

- Achieve energy-efficient operation.

- PLC Program Flowchart:

- Start → Initialization → Read Sensor Data → Execute PID Algorithm → Output Control Signal → Monitor Status → Fault Handling → End

VI. Human-Machine Interface Design

1. Touch Screen Selection

- Model: Kunlun Tongtai TPC7062KS

- Features:

- 7-inch TFT LCD display with a resolution of 800×480.

- Supports Modbus RTU communication protocol.

- Provides a rich library of graphics and controls.

2. Interface Design

- Main Interface:

- Display the washing machine’s operation status, motor speeds, temperature, pressure, and other parameters.

- Provide manual/automatic mode switching buttons.

- Parameter Setting Interface:

- Allow users to modify key parameters such as PID parameters, acceleration/deceleration time, and frequency limits.

- Provide parameter saving and restoration functions.

- Fault Alarm Interface:

- Display fault type, occurrence time, and handling methods.

- Provide fault confirmation and reset buttons.

- Touch Screen Interface Diagram:

- [Main Interface]

- Operation Status: Running

- Washing Pump Speed: 30Hz

- Conveyor Belt Speed: 0.5m/s

- Rotary Brush Speed: 15r/min

- Temperature: 40℃

- Pressure: 0.5MPa

- [Manual/Automatic Switching Button]

- [Parameter Setting Interface]

- PID Proportional Gain: 2.0

- PID Integral Time: 10s

- Acceleration Time: 5s

- Deceleration Time: 5s

- Frequency Limit: 50Hz

- [Save Parameters Button] [Restore Default Button]

- [Fault Alarm Interface]

- Fault Type: Overload Alarm

- Occurrence Time: 2025-04-06 10:00:00

- Handling Method: Check motor load, reduce operating frequency

- [Confirm Fault Button] [Reset Button]

- [Main Interface]

VII. System Integration and Debugging

1. System Integration

- Connect the PLC, inverter, and touch screen through the Modbus RTU bus.

- Configure communication addresses for each device to ensure efficient data exchange.

2. System Debugging

- No-Load Debugging:

- Check whether the rotation direction and speed of each motor are consistent with the design.

- Verify the stability and response speed of the PID control algorithm.

- Load Debugging:

- Test the system’s stability and reliability under different load conditions.

- Adjust parameters to optimize washing effect and energy-saving performance.

- Fault Simulation:

- Simulate faults such as overload and overvoltage to verify the reliability of protection functions.

- Test the real-time performance of fault alarming and reset functions.

VIII. Conclusion

This solution achieves efficient and stable operation of the washing machine through the vector control technology and rich I/O interfaces of the V5-H inverter. Combined with the collaborative control of the PLC and touch screen, it improves the system’s automation level and operational convenience. Through parameter auto-tuning and PID algorithm optimization, it further enhances the washing effect and energy-saving performance. This solution can be widely applied in the cleaning of automobile parts, industrial components, and other fields, with broad market prospects.