Difuss DR5 Series Motor Soft Starter: External Terminal Control Operation and Fault Code Handling Methods

Introduction

The Difuss DR5 Series Motor Soft Starter is an advanced device specifically designed for smooth motor startup and shutdown, widely applied in industrial automation. This article delves into the operational methods for external terminal control and outlines the fault codes along with their corresponding handling procedures, facilitating users in better utilizing and maintaining this equipment.

I. External Terminal Control Operation Methods

1. External Terminal Configuration

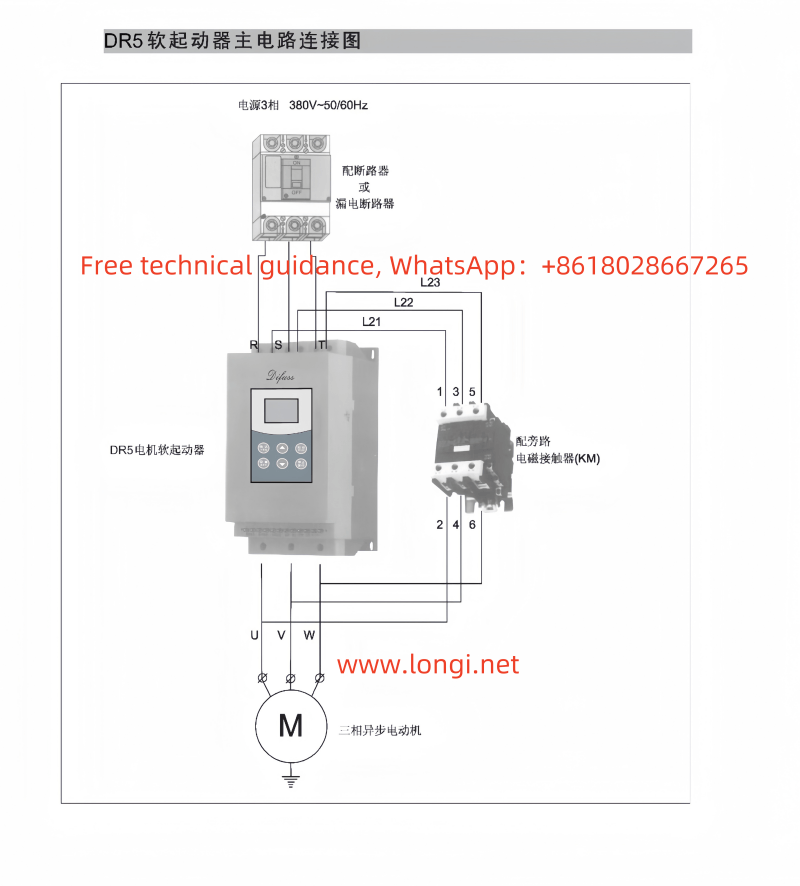

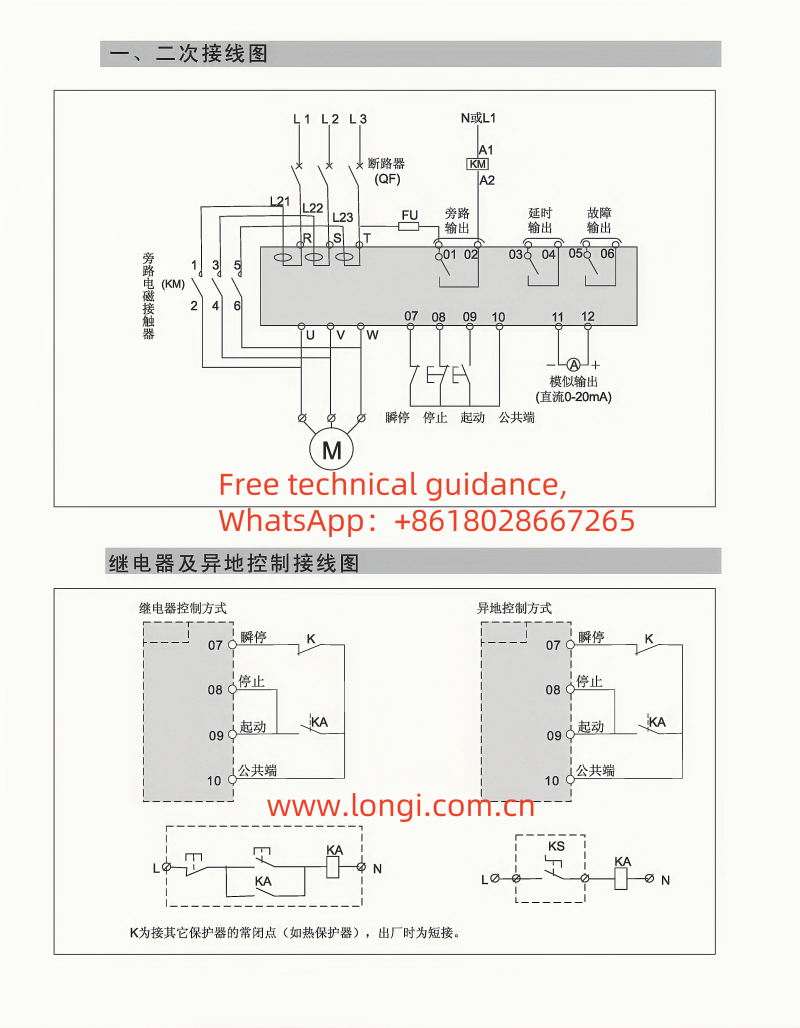

The DR5 Series Soft Starter offers an extensive range of external terminal interfaces for remote control and status feedback. Users should connect external control signals (such as start, stop, reset, etc.) to the corresponding terminals based on their actual needs. Refer to the wiring diagram in the device’s manual for specific terminal configuration.

2. Start Operation

- Power On: First, ensure that the power supply to the soft starter is correctly connected, and the motor wiring is accurate.

- External Start Signal: Send a start signal (typically a normally open contact closure) to the start terminal of the soft starter. Subsequently, the soft starter will initiate the predefined start sequence, smoothly initiating motor rotation.

3. Stop Operation

- External Stop Signal: Transmit a stop signal (also typically a normally open contact closure) to the stop terminal of the soft starter. The soft starter will then gradually reduce the motor’s speed to a stop, following the configured stop mode (e.g., free coasting, soft stop).

4. Reset Operation

- Fault Reset: When the soft starter stops due to a fault, address the fault source first. Then, send a reset signal (either a pulse signal or a sustained closure signal) to the reset terminal to restore the soft starter to its normal state.

II. Fault Codes and Handling Methods

1. Common Fault Codes

During operation, the DR5 Series Soft Starter may encounter various faults, with corresponding fault codes displayed on its screen. Here are some common fault codes and their possible causes:

- F01: Overcurrent Fault. It could be caused by excessive motor load or incorrect motor parameter settings.

- F02: Overload Fault. The motor has been operating in an overloaded state for an extended period.

- F03: Overheat Fault. The internal temperature of the soft starter is too high, potentially due to poor heat dissipation or a high ambient temperature.

- F04: Phase Loss Fault. The input power supply or motor is missing one or more phases.

- F05: Communication Fault. Communication with the host computer or remote control system has been interrupted.

2. Handling Methods

- Check Power Supply and Motor: Verify that the input power supply is normal, the motor wiring is accurate, and there are no short circuits or open circuits.

- Adjust Parameters: Adjust the relevant settings of the soft starter, such as startup time and stop mode, according to the actual motor parameters.

- Improve Heat Dissipation: Clean dust around the soft starter, ensure proper ventilation, and reduce the ambient temperature.

- Check Communication Lines: Inspect the communication lines with the host computer or remote control system to ensure stable and reliable connections.

- Restart the Device: After addressing the fault and resetting, attempt to restart the soft starter to observe whether it returns to normal operation.

Conclusion

The Difuss DR5 Series Motor Soft Starter is a powerful and user-friendly motor control device. By correctly configuring the external terminals, mastering operational methods, and promptly handling fault codes, users can fully leverage its performance advantages, achieving smooth motor startup and shutdown while enhancing production efficiency and equipment safety. We hope this article provides valuable guidance for users in utilizing and maintaining the DR5 Series Soft Starter.