Professional Ultrasonic Equipment Repair Services

Longi Electromechanical Company specializes in the repair of various types of ultrasonic equipment using advanced AI methods and a dedicated technical team. We offer component-level maintenance and can resolve common issues on the same day, minimizing downtime and maximizing customer productivity. With a vast experience of repairing over 2000 ultrasonic devices, we have honed our skills to handle a wide range of brands and models.

Contact Us:

Phone/WhatsApp: +8618028667265

Key Services and Features:

- Comprehensive Repair Solutions: From plastic hot plate welding machines to ultrasonic flaw detectors, we repair a diverse range of ultrasonic equipment.

- Brand Expertise: We have experience with numerous brands, including Minghe, Changrong, Swiss RINCO, and many more, ensuring optimal performance restoration.

- Warranty and Cost-Effectiveness: Repaired equipment comes with a one-year warranty for the same problem point, and our maintenance costs are competitive.

- Quick Turnaround: We prioritize efficient repairs to get your equipment back in operation as soon as possible.

Types of Ultrasonic Equipment We Repair:

- Plastic Welding Equipment: Ultrasonic welding machines, hot plate welding machines, multi-head ultrasonic welding machines, and more.

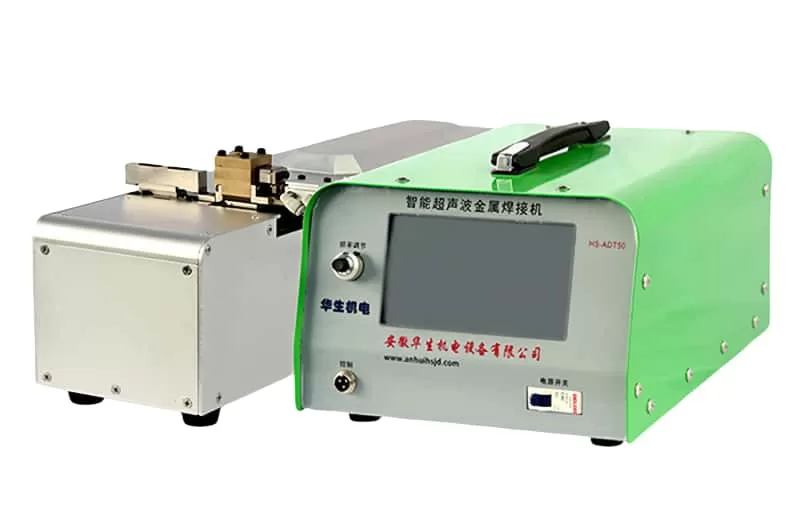

- Metal Welding Equipment: Ultrasonic metal welding machines, spot welding machines, wire welding machines, and roll welding machines.

- Automotive Welding Equipment: Door panel welding machines, interior part welding machines, instrument panel welding machines, and more.

- Specialized Equipment: Ultrasonic flaw detectors, cutting machines, food cutting machines, tool heads, and various other ultrasonic devices.

- Components and Parts: Ultrasonic vibrating plates, power boards, transducers, generators, and supporting tooling.

Common Faults We Address:

- Cleaning water surface not vibrating

- Debonding between vibrator and load

- Mold head misalignment

- No display on startup

- Overload or overcurrent during welding

- High current during testing

- Insufficient or excessive welding heat

- Vibrator leakage waves

- Unresponsive buttons

- Travel protection issues

- Power adjustment problems

- Insufficient ultrasonic intensity

- Cracked transducer ceramic

- Burned-out power tube

- Voltage stabilization issues

- Inductor and isolation transformer problems

- Disconnected vibrator wire

Repair Principles:

- Observe, Understand, Act: Begin by inquiring about the issue from frontline staff, checking for voltage fluctuations, and understanding the context before taking action.

- Simple Before Complex: Rule out peripheral issues like the environment, electricity, load, raw materials, and molds before diving into more complex repairs.

- Address Mechanical Issues First: Visible mechanical problems, such as mold issues, should be addressed before exploring electrical causes.

Trust Longi Electromechanical Company for reliable, efficient, and cost-effective ultrasonic equipment repair services. Contact us today to learn more about our services and how we can help keep your ultrasonic equipment running smoothly.