I. Introduction to Operation Panel Functions and Password Setting/Locking

Introduction to Operation Panel Functions

The operation panel of the LS Inverter LSLV-M100 series integrates display and operation functions, facilitating intuitive operation and monitoring for users. The panel primarily consists of a digital tube display, indicator lights, and buttons. The digital tube is used to display operating status and parameter information, while the indicator lights indicate the current working status, such as running, forward rotation, reverse rotation, etc. The button section includes commonly used function buttons such as run, stop, and fault reset, as well as direction buttons and a confirmation button for parameter setting.

Password Setting and Elimination

To prevent unauthorized parameter modifications, the LSLV-M100 series inverter provides a password protection function. The specific steps for setting a password are as follows:

- Enter the configuration function group: First, access the configuration function group (typically identified by P700 series codes) through the panel operations.

- Select the password registration parameter: Within the configuration function group, locate the password registration parameter (e.g., P701).

- Enter the password: Use the panel’s direction buttons and confirmation button to input the password, which must consist of 1 to 16 hexadecimal characters.

- Save the settings: After inputting, press the confirmation button to save the settings.

The method for eliminating the password is similar to setting it. Simply change the password in the password registration parameter to the initial password (usually 0000) or leave it blank.

Parameter Locking

In addition to password protection, the LSLV-M100 series inverter also offers a parameter locking function. By locking the parameters, unintentional changes can be prevented. The specific steps are as follows:

- Enter the configuration function group: Same as for setting the password, first access the configuration function group.

- Select the parameter locking parameter: Locate the parameter locking parameter (e.g., P702).

- Lock the parameters: Set the parameter locking parameter to 1 to lock all settable parameters.

- Unlock the parameters: When needing to modify parameters, set the parameter locking parameter to 0 and enter the password to unlock.

II. Forward/Reverse Control via Terminals and Speed Adjustment with External Potentiometer

Forward/Reverse Control via Terminals

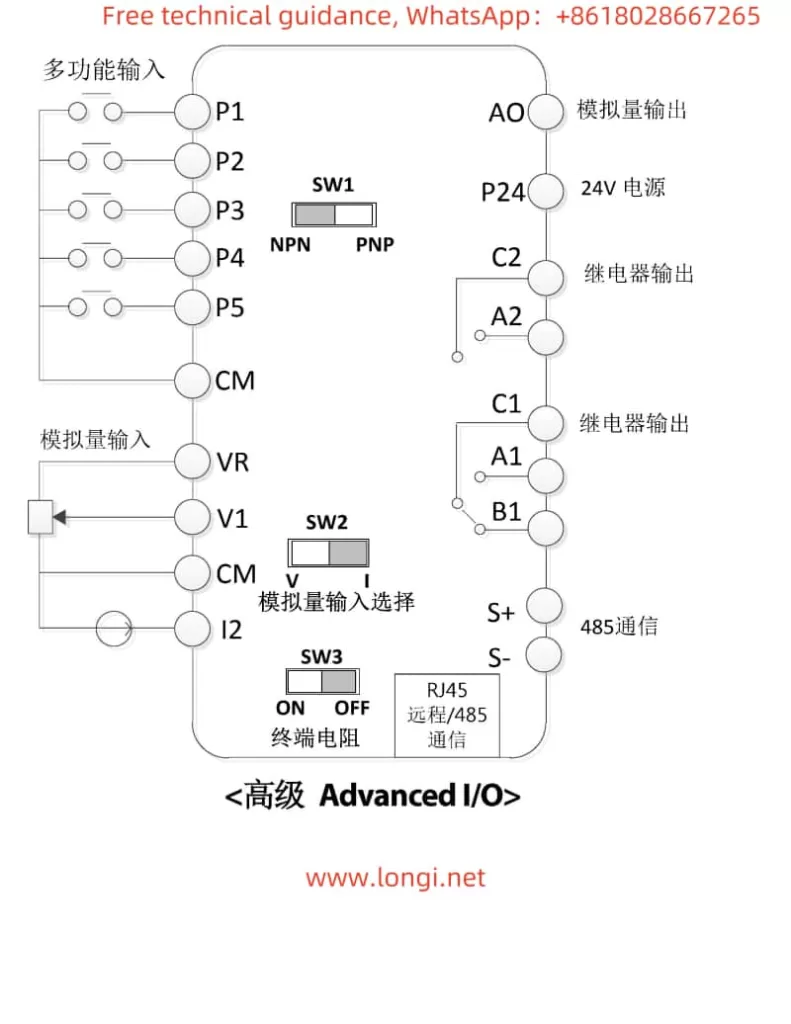

The LSLV-M100 series inverter supports forward/reverse control through multifunction input terminals. The specific wiring and settings are as follows:

- Wiring: Connect the forward control signal to a multifunction input terminal (e.g., IN1) and the reverse control signal to another multifunction input terminal (e.g., IN2).

- Parameter settings:

- Enter the input terminal function group (e.g., P300 series).

- Set the forward control terminal function (e.g., P301) to 1 (forward rotation).

- Set the reverse control terminal function (e.g., P302) to 2 (reverse rotation).

- In the operation group (e.g., P000 series), set the run command source to external terminals.

Speed Adjustment with External Potentiometer

External potentiometer speed adjustment is a commonly used method, where the output frequency of the inverter is changed by adjusting the resistance of the external potentiometer. The specific wiring and settings are as follows:

- Wiring: Connect the two ends of the external potentiometer to the analog input terminals of the inverter (e.g., V1 and GND).

- Parameter settings:

- Enter the input terminal function group.

- Set the analog input terminal function to voltage input (e.g., set P310 to 1 for voltage input).

- In the operation group, set the frequency setting method to analog input (e.g., set P003 to 2 for analog voltage input).

III. Fault Codes and Solutions

The LSLV-M100 series inverter features a comprehensive fault code display function, helping users quickly identify fault causes. Below are some common fault codes, their meanings, and solutions:

- OC (Overcurrent): Indicates that the inverter’s output current exceeds the rated value. Possible causes include excessive load, motor stall, etc. Solutions include checking the load condition and adjusting the acceleration/deceleration time.

- OV (Overvoltage): Indicates that the DC bus voltage of the inverter is too high. Possible causes include excessive input voltage and faulty braking resistor. Solutions include adjusting the input voltage and checking the braking resistor.

- UV (Undervoltage): Indicates that the input voltage of the inverter is too low. Possible causes include unstable power supply voltage and phase loss in the input power supply. Solutions include checking the power supply voltage and the input power lines.

- OH (Overheat): Indicates that the temperature of the inverter’s heatsink is too high. Possible causes include high ambient temperature and faulty cooling fan. Solutions include reducing the ambient temperature and replacing the cooling fan.

For the above faults, users can follow the fault troubleshooting process outlined in the manual to identify and resolve issues one by one based on the inverter’s fault code prompts.

IV. Conclusion

As a high-performance variable frequency speed control device, the LSLV-M100 series inverter provides a detailed operation guide and fault troubleshooting methods in its user manual. By familiarizing themselves with the functions of the operation panel, mastering password setting and locking, understanding the wiring and settings for forward/reverse control via terminals and speed adjustment with an external potentiometer, and grasping the solutions to common fault codes, users can operate and maintain the inverter more efficiently, ensuring its stable operation and optimal performance.