The TECO Inverter 7200GS, as a high-performance universal inverter, is widely used in industrial automation due to its support for various control modes including V/F control, Sensorless Vector Control, PID energy-saving control, and V/F+PG closed-loop control. This article will provide a detailed introduction to key operations of the TECO Inverter 7200GS, including panel startup, frequency speed regulation, password function setup and unlocking, as well as fault code analysis.

I. Panel Startup

1. Inspection and Preparation

- Verify the Inverter Installation Environment: Check if the surrounding temperature, humidity, and ventilation conditions meet the requirements, ensuring no corrosive gases or dust.

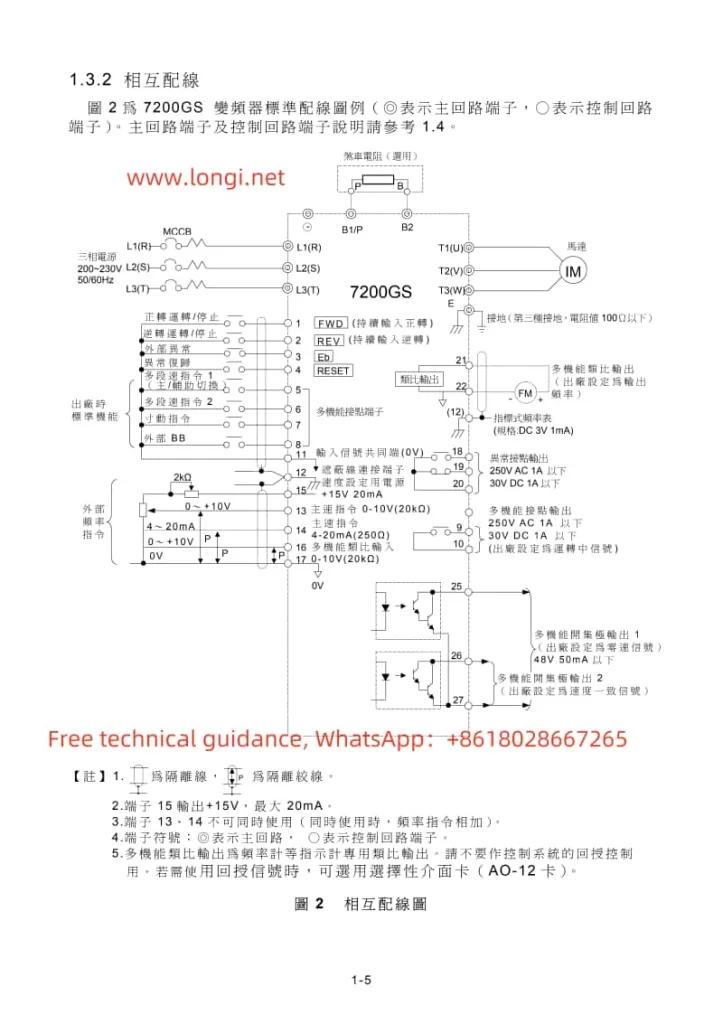

- Electrical Inspection: Ensure all electrical connections, particularly the input/output power supply and motor connections, are correct.

2. Power-On Startup

- Connect the main power supply to the inverter. The “CHARGE” indicator light will illuminate, indicating that the internal capacitor is charging.

- Once the “CHARGE” indicator light goes out, it means charging is complete, and the inverter is ready for operation.

3. Panel Operation

- Use the standard LCD or LED operator panel to switch to the “DRIVE” mode.

- Press the “RUN” button to start the inverter, and the motor will subsequently operate.

II. Panel-Set Frequency Speed Regulation

1. Enter Frequency Setting Mode

- In the “DRIVE” mode, navigate to the frequency setting interface using the number keys and direction keys on the panel.

- Use the direction keys to select the “Frequency Command” option and input the desired frequency value using the number keys.

2. Speed Regulation Operation

- After entering the frequency value, press the “ENTER” key to confirm, and the inverter will adjust the motor speed according to the set frequency value.

- Smooth speed regulation can be achieved by continuously changing the frequency value.

III. Password Function Setup and Unlocking

1. Password Setup

- With the inverter stopped, enter the parameter setting mode through the panel.

- Locate the parameter related to password setup (e.g., Sn-xx) and input the desired password value according to your needs.

- Save the parameter settings and exit the setup mode after completing the password setup.

2. Password Unlocking

- To unlock a set password protection, re-enter the parameter setting mode.

- Input the correct password value, save, and exit the setup mode to remove the password protection.

IV. Fault Code Analysis

1. UV1 (Under Voltage)

- Fault Description: The DC main circuit voltage is too low during operation.

- Possible Causes: Insufficient power supply capacity, voltage drop in wiring, improper inverter power supply voltage selection, etc.

- Countermeasures: Check the power supply voltage and wiring, verify the power supply capacity and system, install an AC reactor, etc.

2. OC (Over Current)

- Fault Description: The inverter output current exceeds 200% of the rated current.

- Possible Causes: Short acceleration time, short circuit or grounding at the output terminals, motor capacity exceeding the inverter capacity, etc.

- Countermeasures: Extend the acceleration time, check the output terminal wiring, replace the inverter with an appropriate capacity, etc.

3. OL3 (Over Load)

- Fault Description: Excessive output torque triggers the over-torque protection.

- Possible Causes: Abnormal mechanical load, improper over-torque detection level settings, etc.

- Countermeasures: Inspect the mechanical operation, set an appropriate over-torque detection level, etc.

4. PG0 (PG Disconnection)

- Fault Description: Disconnection of the PG (encoder) signal.

- Possible Causes: Poor contact or disconnection in the PG wiring.

- Countermeasures: Check the PG wiring to ensure proper contact.

V. Conclusion

The TECO Inverter 7200GS, as a powerful inverter, offers flexible speed regulation, startup, and protection functions. Through this article, users can better understand and master key operations such as panel startup, frequency speed regulation, password settings, and fault code analysis, thereby enhancing equipment efficiency and stability. In practical applications, users should configure inverter parameters according to specific needs and environmental conditions to ensure proper operation.