AT500 Inverter Operation Guide and Fault Handling Summary

I. AT500 Inverter Operation Panel Usage

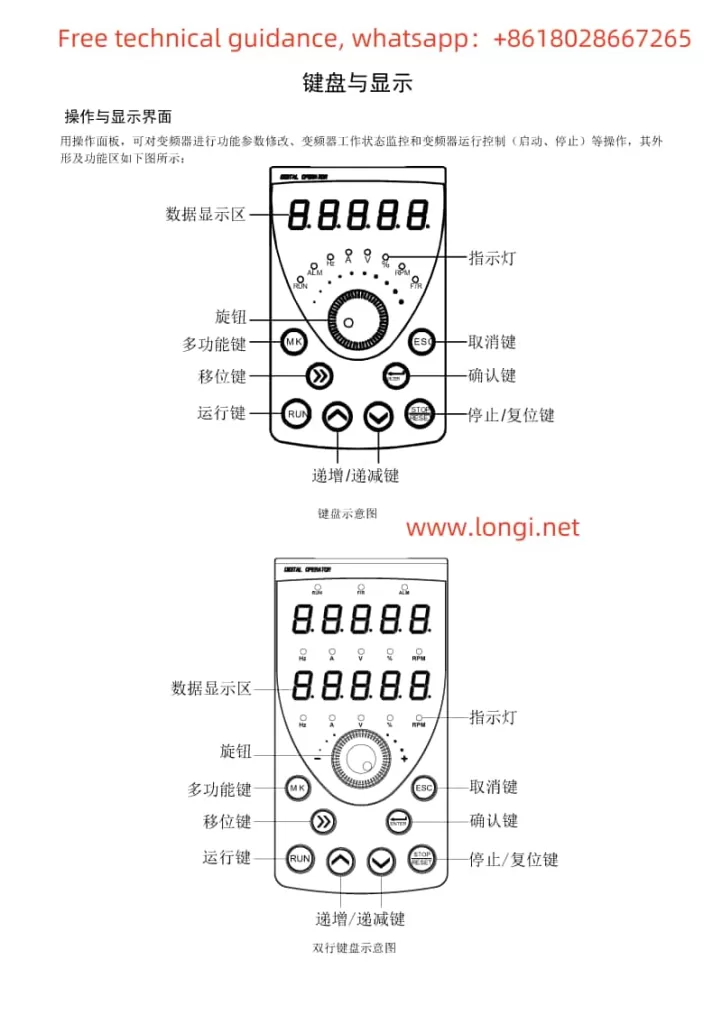

- Operation Panel Layout and Indicator Description:

- Introduces the display, buttons (RUN, STOP/RES, MK, Λ, V, >>, etc.) on the operation panel and their functions.

- Explains the meanings of various indicators (Run, Alm, Hz, A, V, %, rpm, F/R, etc.).

- Menu and Parameter Settings:

- Describes the three-level menu mode (function parameter group, function code, function code modification) and its operation method.

- Elaborates on how to view and modify various inverter parameters through the operation panel.

- Operation Mode Control:

- Introduces starting the inverter via the RUN button and stopping it via the STOP/RES button.

- Explains the jog operation function and its debugging applications.

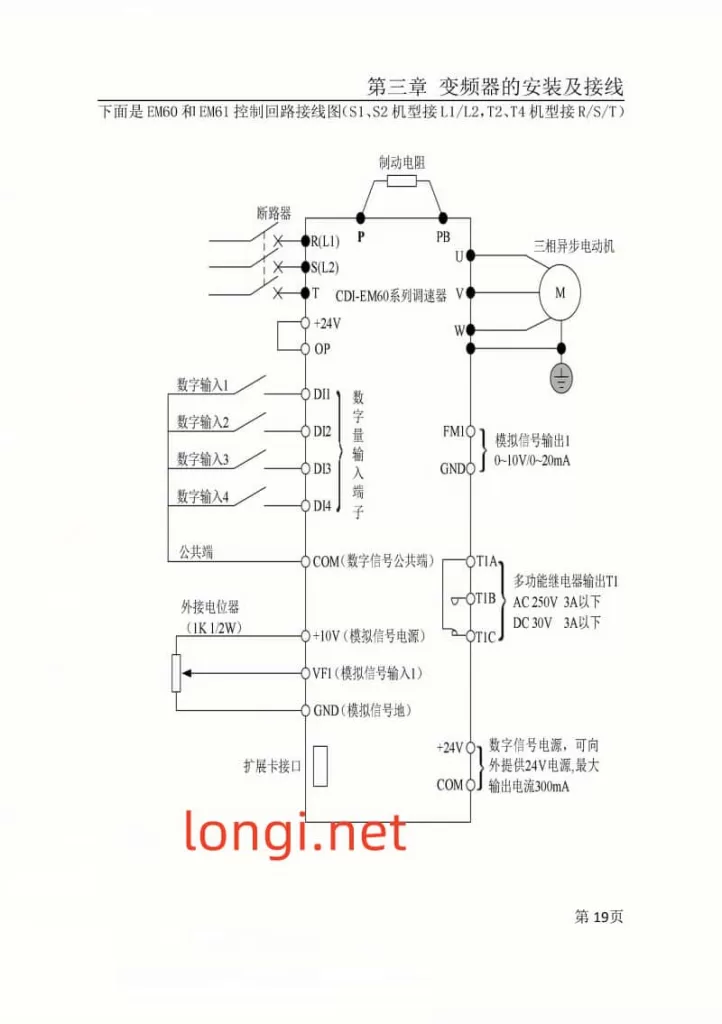

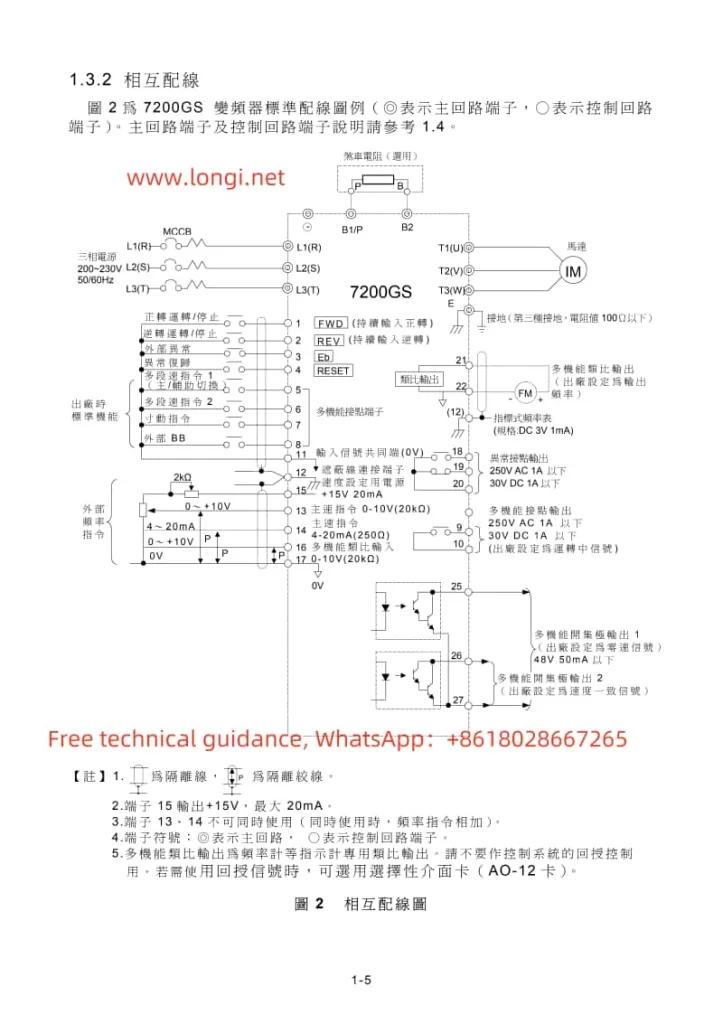

II. Terminal Control and External Potentiometer Debugging Mode Setup

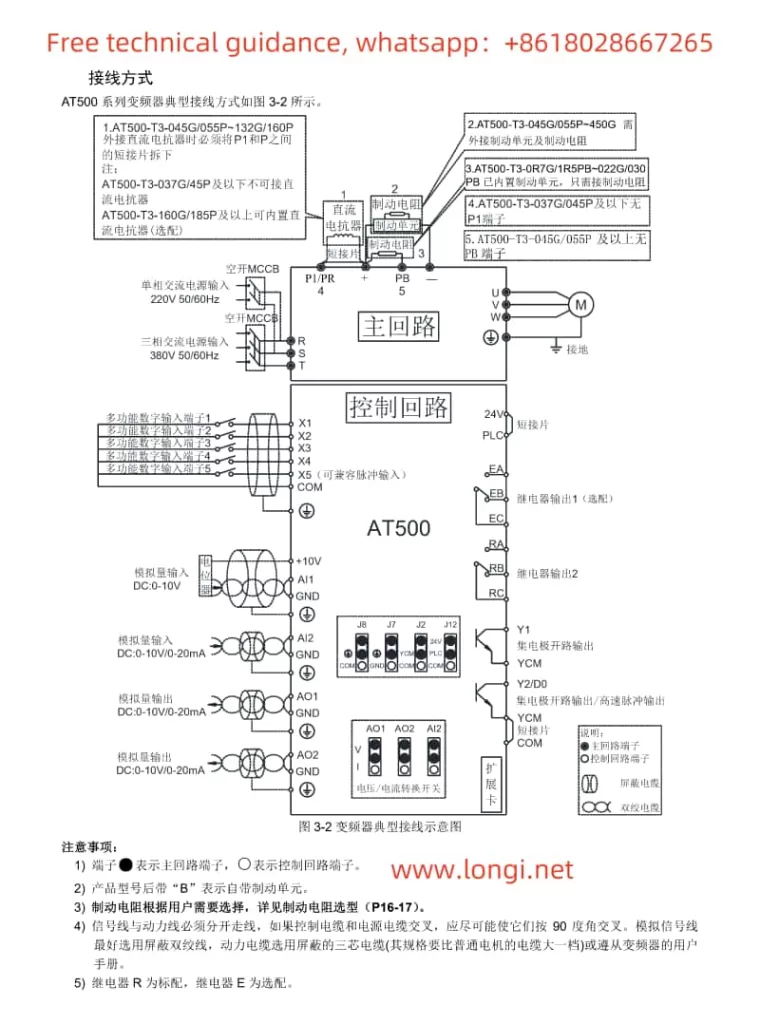

- Terminal Control Setup:

- Guides users to enter the F0 parameter group and set F0.02 to 1 to enable terminal control.

- Demonstrates how to assign functions to each input terminal through the F2 parameter group and explains wiring requirements.

- External Potentiometer Debugging Mode:

- Teaches users to set F0.03 or F0.04 to AI3 (keyboard potentiometer) to adjust the output frequency by rotating the potentiometer knob.

III. Inverter Fault Code Classification and Troubleshooting Methods

- Overcurrent Faults (Err02-Err04):

- Lists possible causes (output circuit short circuit, too short acceleration/deceleration time, etc.).

- Provides solutions (check output circuit, adjust acceleration/deceleration time, etc.).

- Overvoltage Faults (Err05-Err07):

- Analyzes fault causes (excessively high input voltage, external force during deceleration, etc.).

- Offers remedies (adjust input voltage, eliminate external force during deceleration, etc.).

- Undervoltage Fault (Err09):

- Describes fault causes (instantaneous power failure, low input voltage, etc.).

- Suggests solutions (check input power supply, adjust voltage range, etc.).

- Overload Faults (Err10-Err11):

- Indicates faults may be caused by excessive load, motor stall, etc.

- Proposes reducing the load, checking the motor and mechanical conditions, etc.

- Input/Output Phase Loss Faults (Err12-Err13):

- Analyzes fault causes (input power phase loss, faulty output wires or motor, etc.).

- Offers advice on checking power and motor, troubleshooting peripheral faults, etc.

- Module Overheating Fault (Err14):

- Explains fault causes (high ambient temperature, blocked air ducts, etc.).

- Emphasizes the importance of reducing ambient temperature, cleaning air ducts, replacing fans, etc.

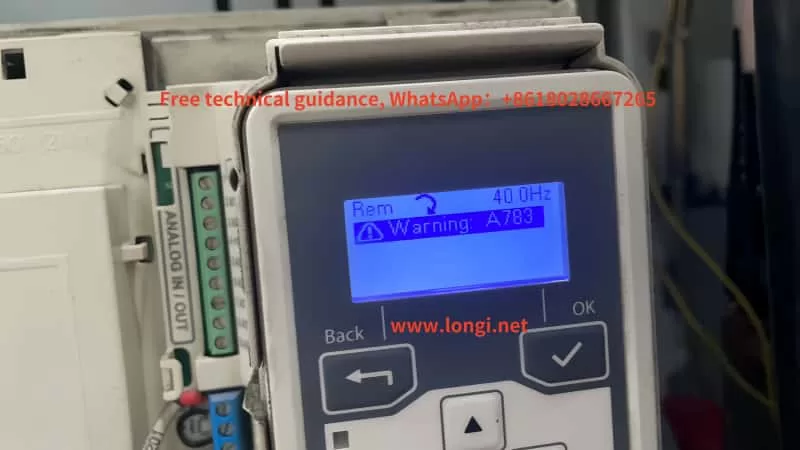

- Communication Fault (Err16):

- Mentions possible causes (incorrect communication parameter settings, faulty communication cables, etc.).

- Suggests checking communication parameters, cables, and the host computer.