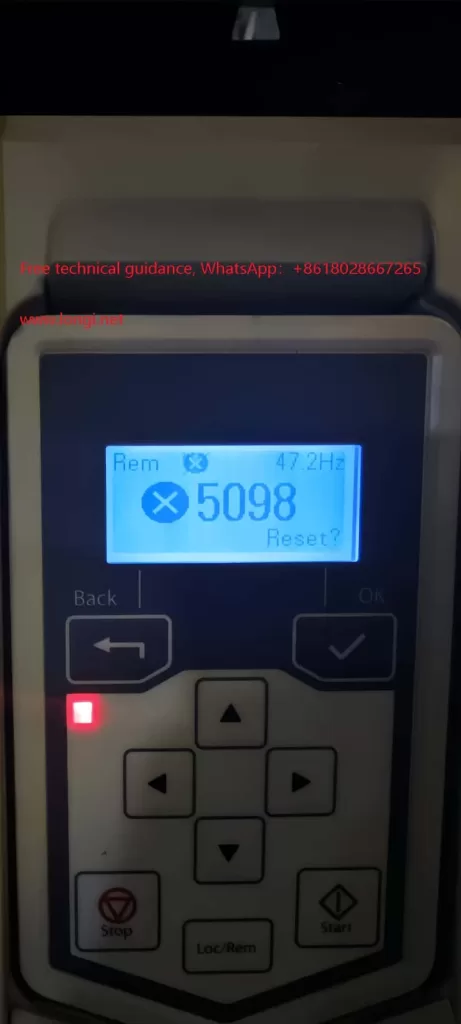

ACS530 VFD 5098 Alarm Fault Analysis and Troubleshooting

When working with ABB’s ACS530 series VFDs (Variable Frequency Drives), encountering specific fault alarms such as the 5098 alarm can be a concern. While the ACS530 series manual may not directly mention this alarm code, by referencing the manual of its similar ACS580 series VFDs, also from ABB, we can gain insight into the 5098 alarm and apply that knowledge to troubleshooting the ACS530 series.

I. Understanding the 5098 Alarm

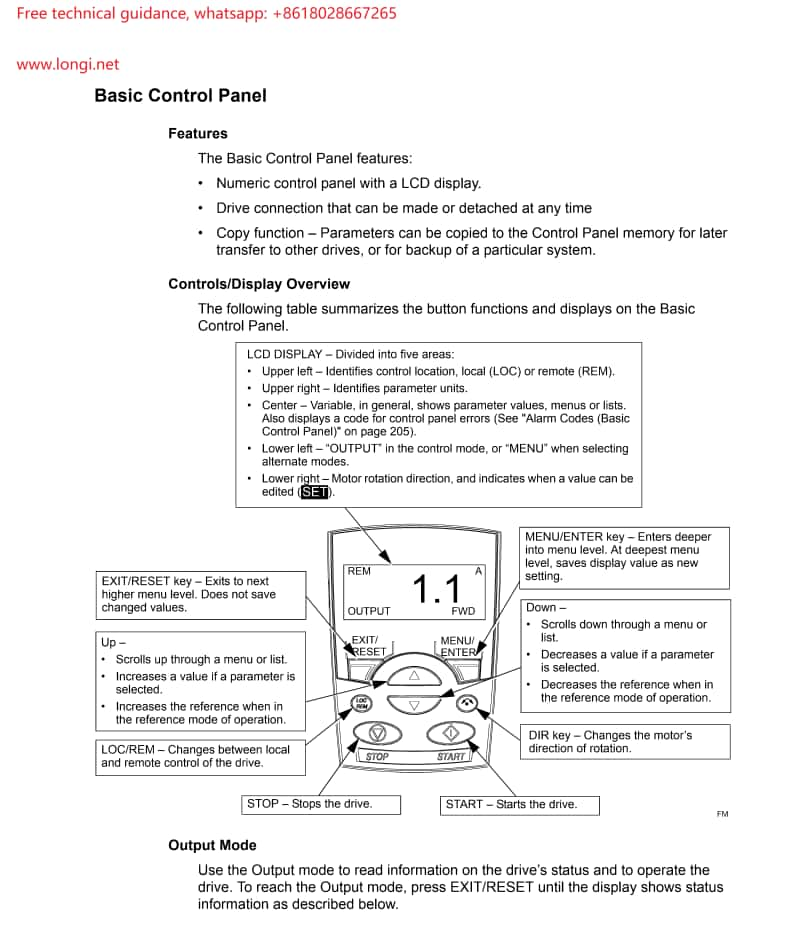

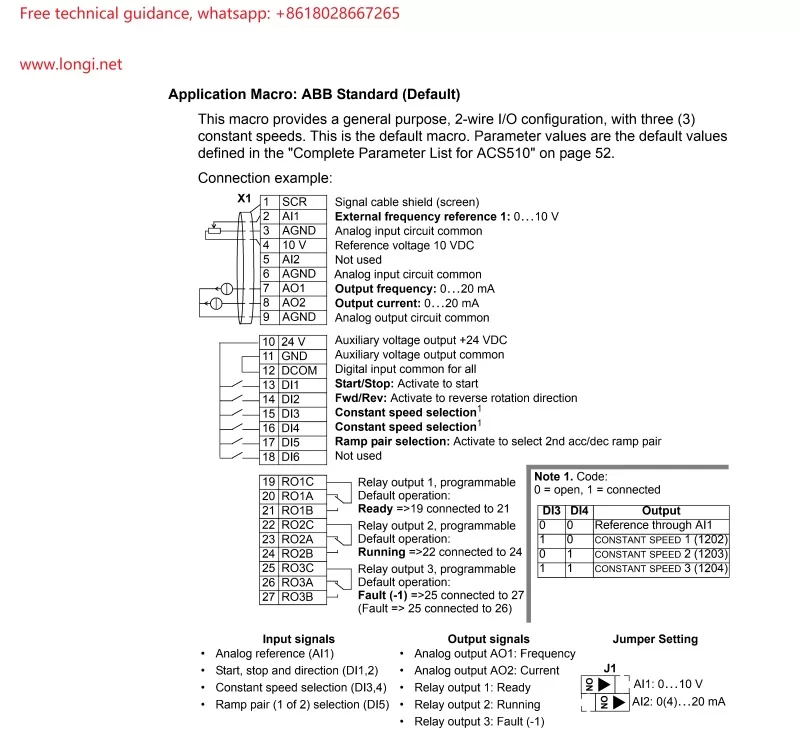

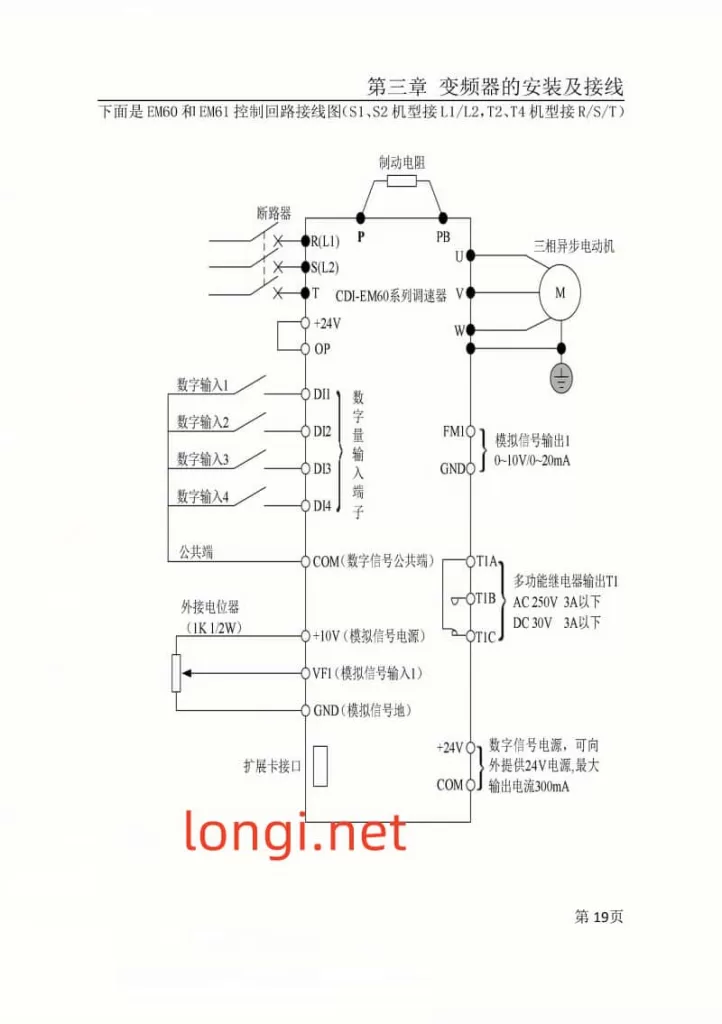

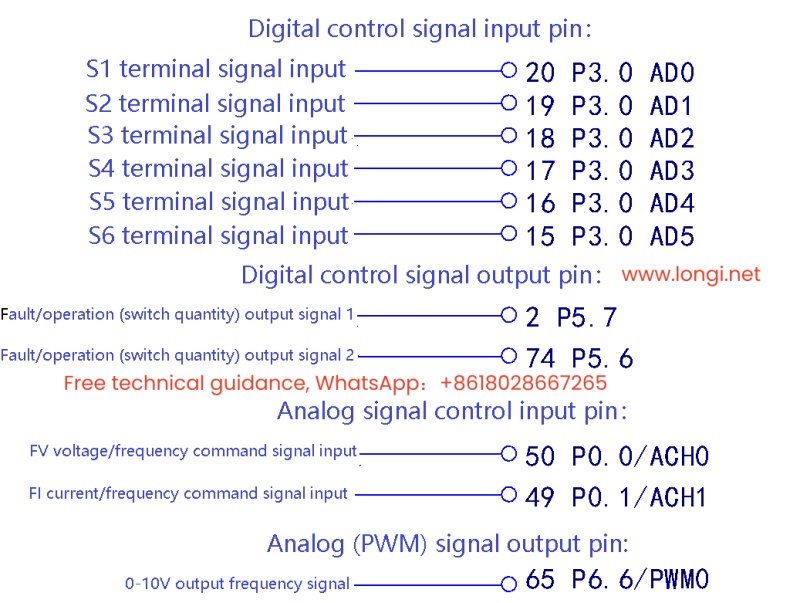

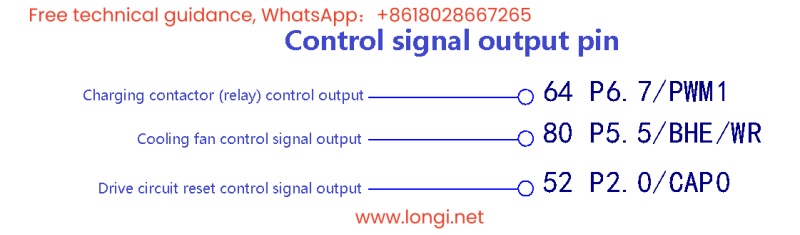

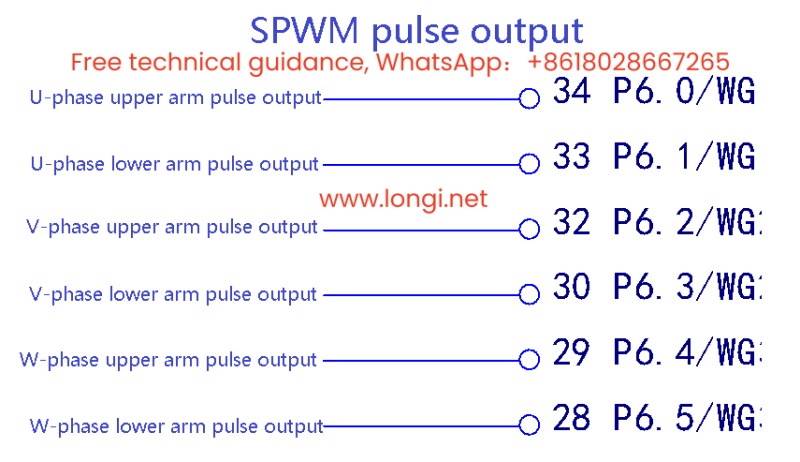

In the ACS580 series, the 5098 alarm indicates “I/O Communication Lost,” signifying a failure in communication with the standard I/O (Input/Output) devices. This usually occurs when there is an issue with the communication link between the VFD’s I/O terminal board (where analog inputs like AI1 reside) and the main board. Similarly, in the ACS530 series, the 5098 alarm likely indicates a communication issue as well.

II. Possible Causes of the Fault

- Power Issues:

- The 10V or 24V power supply on the I/O terminal board may be abnormal, leading to unstable or failed communication.

- There may be short circuits, open circuits, or poor connections in the power lines.

- Hardware Connection Problems:

- Connections between the I/O terminal board and the main board may be loose, have cold solder joints, or be corroded.

- Terminals may have aged due to prolonged use, resulting in poor contact.

- Communication Module Failure:

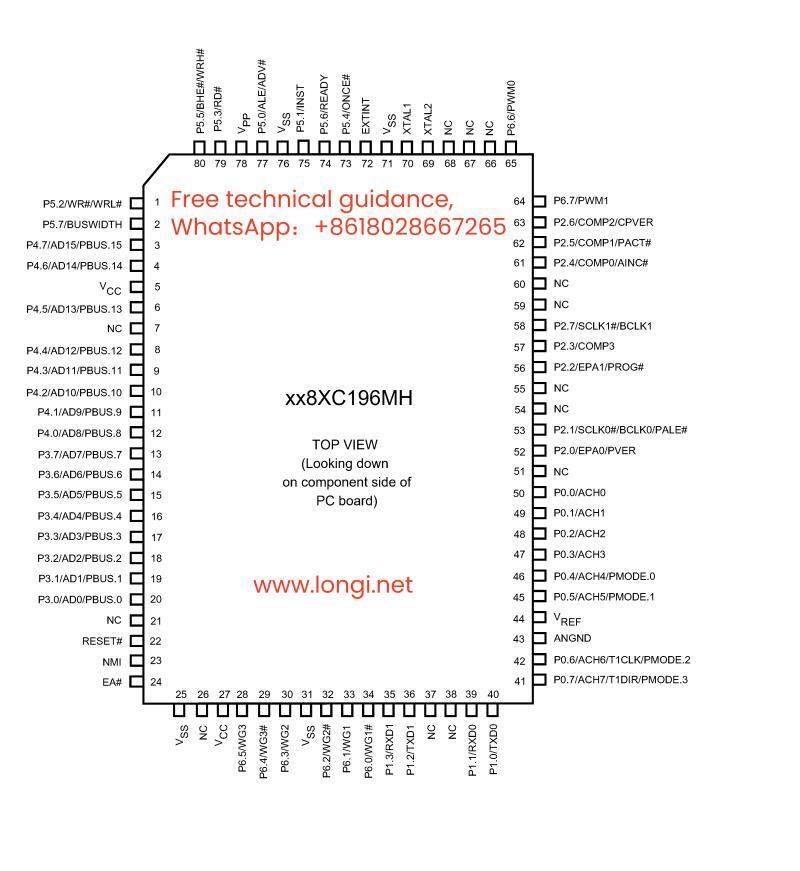

- The VFD’s I/O communication module may be damaged, preventing proper communication with the I/O terminal board.

- Software or Configuration Issues:

- The VFD’s software configuration may have errors, affecting communication protocols or parameter settings.

- Despite similarities in design and software between the ACS530 and ACS580 series, subtle differences in configuration may lead to unexpected alarms in the ACS530 under certain conditions.

III. Fault Troubleshooting Steps

To address the 5098 alarm in the ACS530 VFD, follow these troubleshooting steps:

- Check Power Supplies:

- Use a multimeter to verify the 10V and 24V power supplies on the I/O terminal board are functioning correctly.

- Inspect power lines for completeness, shorts, or open circuits.

- Inspect Hardware Connections:

- Disconnect all connections related to the I/O terminal board, reconnect them securely, and ensure they are tight.

- Examine the connections between the I/O terminal board and the main board for looseness, cold solder joints, or corrosion, and make necessary repairs.

- Assess Communication Module:

- If possible, test replacing the I/O communication module with an identical one to determine if it’s faulty.

- Reset and Restart:

- Attempt to reset the VFD to clear the alarm.

- If resetting fails, power off the VFD, wait for a while, and then power it back on to eliminate any software-related communication issues.

- Contact Technical Support:

- If none of the above steps resolve the issue, contact ABB’s technical support team or a professional service provider for further diagnosis and repair.

IV. Conclusion

Despite the ACS530 series VFD manual’s lack of direct mention of the 5098 alarm, referencing similar ACS580 series documentation and contextual analysis enables understanding the likely fault type and appropriate troubleshooting methods. In practice, consider all potential causes