Proper maintenance and servicing of the NETZSCH TG209 Thermogravimetric Analyzer are crucial for ensuring its long-term stable operation and measurement accuracy. Below are key steps and considerations for maintenance:

I. Daily Cleaning

- Sample Plate Cleaning: Before and after each measurement, the sample plate should be kept clean. Prior to sample placement, use air to blow off dust or an appropriate cleaning solution to clean, ensuring no damage to the sample.

- Temperature Controller Cleaning: Regularly clean the temperature controller with a cleaning solution or air to ensure accurate temperature settings.

- Computer Cleaning: Regularly clean the interior and exterior of the computer, as well as input/output devices. It is recommended to clean at least once a year.

II. Component Inspection and Replacement

- Accessory Inspection: Regularly inspect accessories such as heating elements, controllers, and temperature sensors to ensure they are in good condition. Timely replace aged or damaged components.

- Filter Replacement: Replace oil absorption filters, filter elements, and gas filters regularly based on usage to prevent contaminants from affecting measurement results.

- Seal Ring Inspection and Replacement: Regularly inspect the main unit and analyzer for oil leaks. If found, promptly replace seal rings or gaskets.

III. Software and System Settings

- Software Updates: Keep the control software of the thermogravimetric analyzer up to date to utilize the latest features and bug fixes.

- System Configuration: Ensure all system settings, such as temperature range and heating rate, are correct to meet experimental requirements.

IV. Regular Maintenance

- Professional Maintenance: Apply for regular maintenance services from NETZSCH or authorized service centers, including deep cleaning, calibration, and performance checks.

- Long-term Storage: If the thermogravimetric analyzer will be unused for a long period, store and maintain it according to the manufacturer’s recommendations to prevent component aging and damage.

V. Operational Precautions

- Sample Preparation: Ensure samples are in a uniform powder state and that sample pans are dry to reduce measurement errors.

- Operational Norms: Follow the operational procedures and safety guidelines of the NETZSCH TG209 Thermogravimetric Analyzer during operation to ensure the safety of operators and equipment.

- Maintenance Log: Establish a maintenance log to record the time, content, and replaced components of each maintenance, facilitating the tracking of equipment maintenance history and performance changes.

VI. Specific Maintenance Tasks

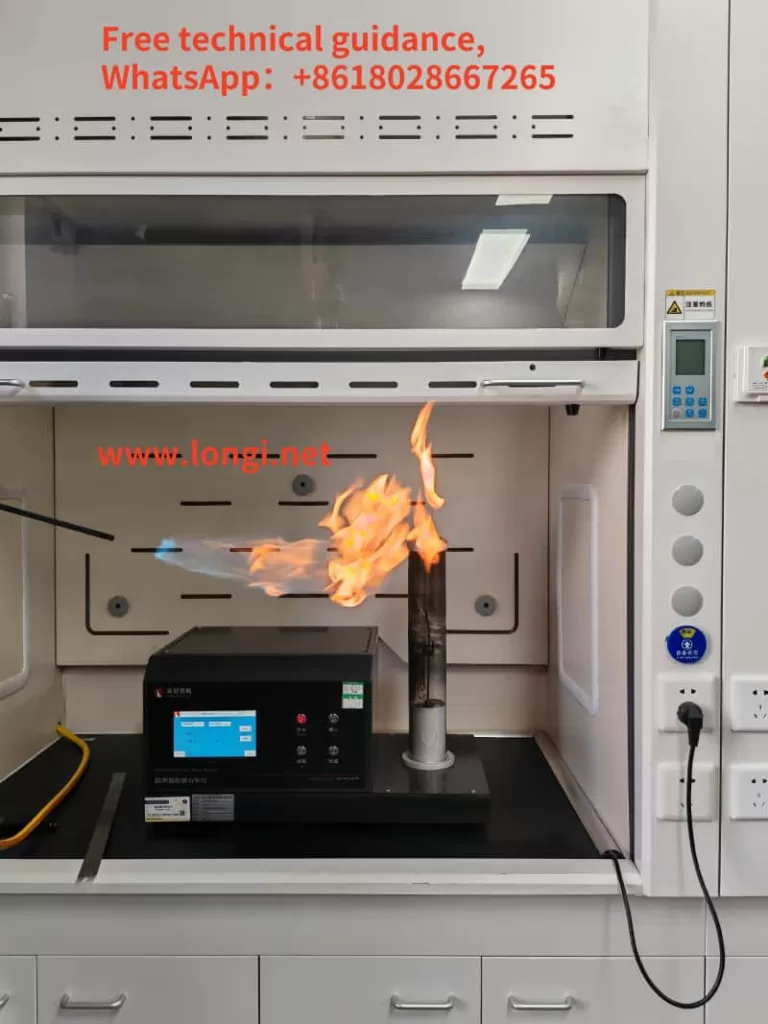

- Support Rod Cleaning: After long-term use, residue from sample decomposition may adhere to the support rod, affecting test accuracy. Therefore, regularly burn the support rod at high temperatures in air or oxygen to remove residue (typically once a week, depending on sampling frequency and instrument contamination).

- Furnace Maintenance: For models such as the NETZSCH TG209F1 with ceramic furnaces, special attention should be given to the furnace’s corrosion resistance and sealing. Regularly inspect the furnace for cracks or damage and promptly repair.

In summary, the maintenance and servicing of the NETZSCH TG209 Thermogravimetric Analyzer require comprehensive consideration of daily cleaning, component inspection and replacement, software and system settings, regular maintenance, operational precautions, and specific maintenance tasks. Through scientific maintenance measures, the long-term stable operation and measurement accuracy of the instrument can be ensured.