Global Touch Screen Repair Services: Expert Maintenance for All Your Touch Screen Needs

Touch screens have become an integral part of our daily lives, revolutionizing the way we interact with machines in various industries including industrial, commercial, and medical fields. These versatile devices come in different forms such as resistive, capacitive, infrared, and ultrasonic screens, each serving unique purposes. However, due to their frequent use and delicate glass structure, touch screens are prone to damage, particularly to the outer touch surface known as the “touchpad.”

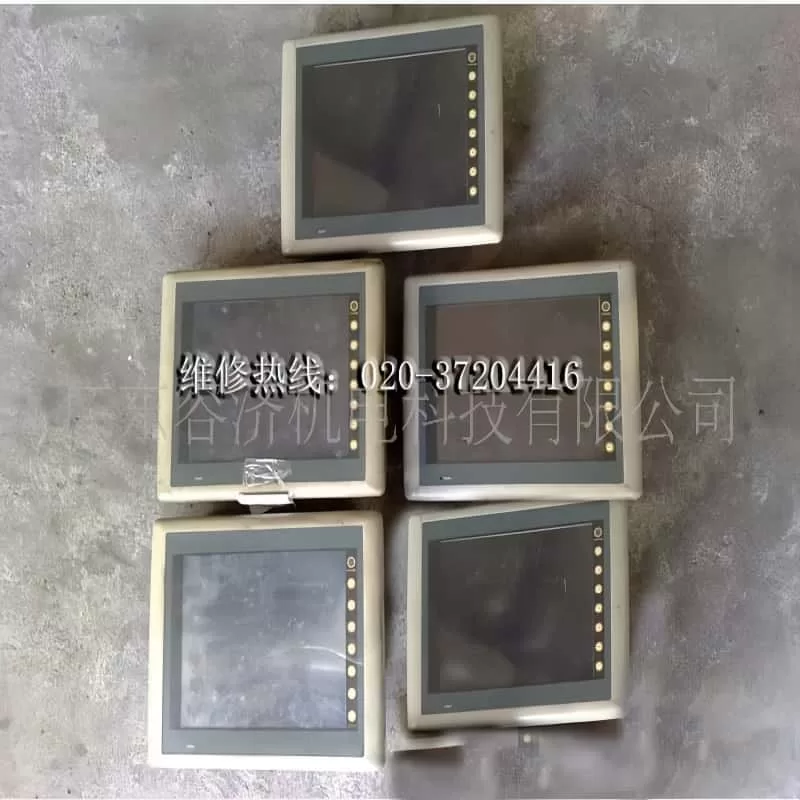

For over two decades, Rongji Electromechanical Maintenance has been a trusted name in the touch screen repair industry. With extensive experience in handling touch screens across diverse sectors, we specialize in repairing both resistive and capacitive screens used in automobiles and other critical applications. Our expertise ensures that your touch screens are restored to optimal functionality, minimizing downtime and maximizing efficiency.

The Repair Process: A Step-by-Step Guide

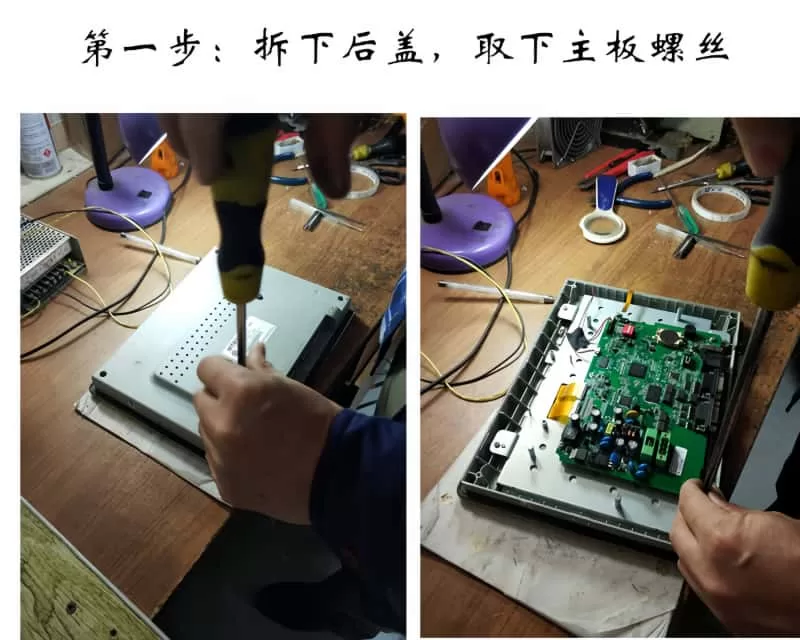

Disassembly and Inspection:

We begin by carefully removing the back cover and motherboard screws of the touch screen. This step allows us to access the internal components and assess the extent of the damage.

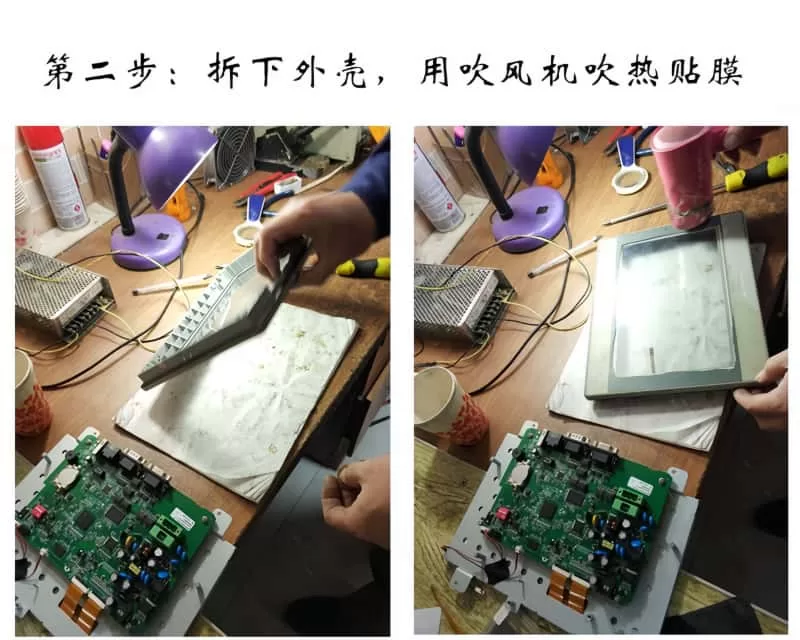

Heating and Peeling:

Our skilled technicians use a hair dryer to gently heat the film adhering to the touch screen. This softens the adhesive, making it easier to peel off the outer layer without causing further damage.

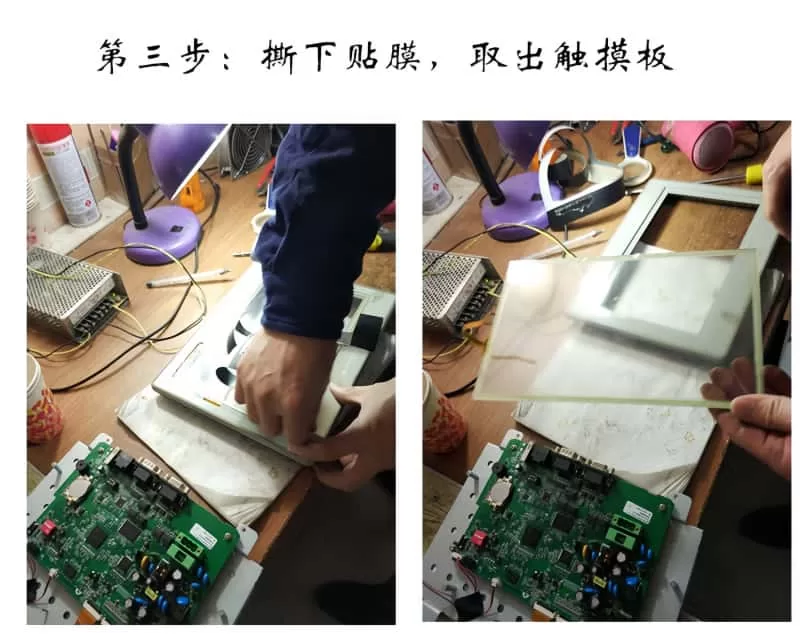

Touchpad Replacement:

Once the old touchpad is removed, we replace it with a high-quality touchpad from our inventory. Longi Electromechanical Company has reverse-engineered various touch screen models, ensuring that our replacement parts are fully compatible with the original equipment.

Reassembly:

We apply double-sided tape to the touch screen border and securely attach the new touchpad. This ensures a perfect fit and optimal performance.

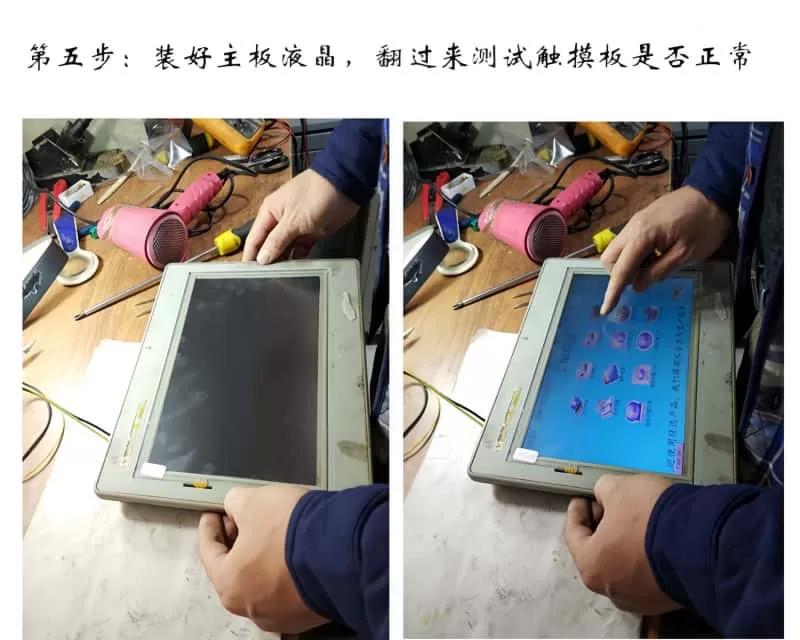

Testing and Fine-Tuning:

With the new touchpad in place, we reinstall the motherboard and LCD, then flip the unit over to test its functionality. Our rigorous testing process ensures that the touch screen operates smoothly and accurately.

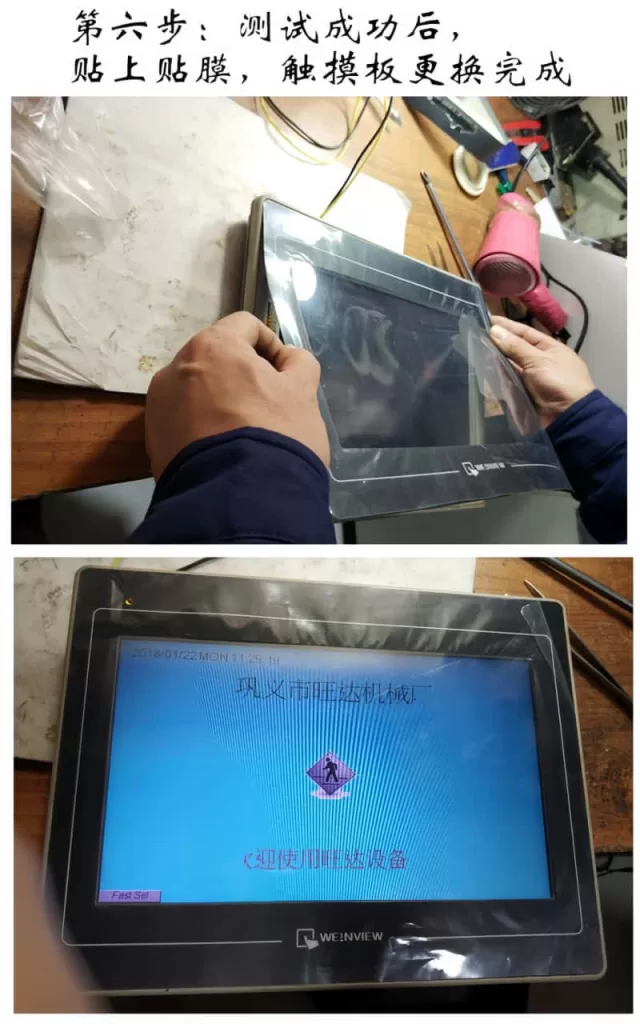

Final Assembly and Quality Check:

After successful testing, we apply a protective film to the touch screen and reassemble the unit. A final quality check is performed to ensure that the repair meets our high standards.

Addressing Complex Issues

In addition to touchpad replacements, we also handle more complex issues such as circuit failures and software problems. Our team uses professional software analysis and hardware processing techniques to diagnose and repair these issues, ensuring that your touch screen is fully restored to its original state.

Our Repair Services Cover a Wide Range of Brands

At Rongji Electromechanical Company, we have repaired touch screens from numerous brands including Siemens, Proface, Mitsubishi, Fuji, Panasonic, OMRON, and many more. Our extensive experience and expertise enable us to provide reliable repair services for a wide variety of touch screen models.

Common Touch Screen Problems We Solve

- Unresponsive Touch Screen: If your touch screen is visible but cannot be touched or clicked, it may be due to a faulty touch panel. Our experts can replace the panel to restore functionality.

- No Display: If your touch screen does not display anything and the indicator lights are off, it could be a power supply issue. We can diagnose and repair the problem to get your touch screen back up and running.

- Black Screen: If your touch screen functions but displays a black screen, it may be due to a burned-out backlight tube. We can replace the tube to restore the display.

- Distorted Image or Abnormal Colors: Issues with the LCD or connecting cables can cause distorted images or abnormal colors. Our technicians can diagnose and repair these issues to ensure clear and accurate display.

- Communication Errors: If your touch screen displays a communication error and responds slowly to touch, it may be due to issues with the PLC or other connected devices. We can troubleshoot and repair the connection to ensure smooth communication.

Choose Rongji Electromechanical Maintenance for reliable and professional touch screen repair services. Contact us today to learn more about our services and how we can help you keep your touch screens in optimal condition.WhatSapp:+8618028667265 ;Zalo:+8613922254854