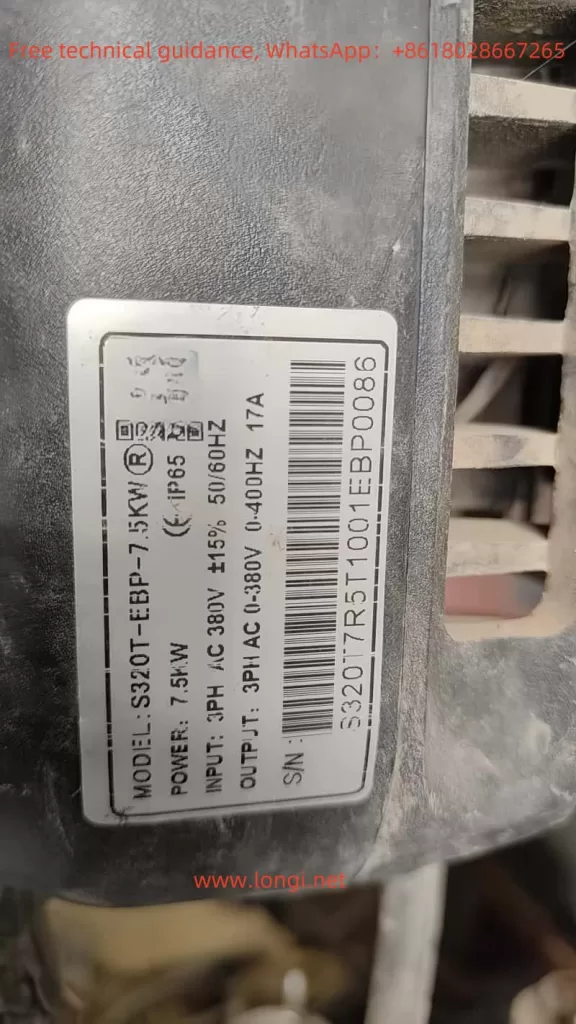

The WELLER S320 Inverter, as a powerful variable frequency speed control device, is widely used in various industrial control systems. To ensure its correct and efficient operation, this article will provide a detailed operation guide for the WELLER S320 Inverter, covering four main aspects: sensor selection and settings, external start mode and return water control settings, relay output function settings, and fault code analysis and troubleshooting.

I. Sensor Selection and Settings

As the “eyes” of the inverter, the type and range of the sensor directly affect the system’s accuracy and stability. The WELLER S320 Inverter supports both voltage and current sensors. When choosing the sensor type, it is necessary to consider the actual application scenario and system requirements. Voltage sensors are suitable for situations requiring high signal stability, while current sensors are more suitable for long-distance transmission or environments with high interference.

Setting the sensor range is equally important. The WELLER S320 Inverter offers three ranges: 0.0-10.0 bar, 0.0-16.0 bar, and 0.0-25.0 bar. During setting, it is essential to select a range that reasonably covers the system’s operating pressure to ensure the sensor can accurately reflect the system status.

Pressure calibration is a crucial step to ensure the accuracy of the inverter. By adjusting parameter E0.04, the sensor can be calibrated. During the calibration process, ensure the system is in a stable state to avoid external interference affecting the calibration results.

Parameters related to pressure deviation include wake-up pressure deviation (E0.05) and high-pressure alarm deviation (E0.06). The wake-up pressure deviation sets the pressure threshold for the inverter to wake up, while the high-pressure alarm deviation sets the threshold for the high-pressure alarm. Properly setting these two parameters can effectively protect the system from excessive or too low pressure.

The PID sleep and wake-up functions are important means to improve system energy efficiency. By setting parameter E2.07 to 1, the PID sleep function can be enabled. At the same time, by adjusting parameters E2.08 and E2.09, the PID wake-up delay and sleep deviation pressure can be set to meet the needs of different systems.

The water shortage protection function is essential for protecting pumps and preventing system damage. By setting parameter E0.19 to 1 or 2, the water shortage protection function can be enabled. It is also necessary to reasonably set parameters such as E0.20 (water shortage fault detection threshold), E0.21 (water shortage protection frequency), and E0.22 (water shortage protection detection current percentage) to ensure that the water shortage protection function can accurately and timely respond to changes in the system status.

II. External Start Mode and Return Water Control Settings

Setting the inverter to external start mode allows convenient control of the inverter’s start and stop through external signals. By setting parameter E0.08 to 1 and selecting the appropriate DI function (e.g., setting E0.29 to 1), the external start function can be achieved. Simultaneously, by adjusting parameter E0.28, the power-on self-start delay time can be set to meet the start-up requirements of different systems.

Return water control is an important application of the inverter in heating, water supply, and other fields. By setting parameter E5.06 to 1 or 2, the return water control mode can be enabled. It is also necessary to reasonably set parameters such as E5.00 (return water temperature set value), E5.01 (return water shut-off temperature offset), E5.02 (maximum operating time of return water control), and E5.03 (allowable time interval for return water control operation) to ensure the stable operation of the return water control system and meet actual needs.

The relay output function is a crucial means to realize the联动 control between the inverter and other devices. By setting parameter E0.34, different relay output functions can be selected, such as forward operation, reverse operation, fault output, etc. Simultaneously, by adjusting parameters E0.35 and E0.36, the relay closing and opening delay times can be set to meet the control requirements of different systems.

III. Fault Code Analysis and Troubleshooting

The WELLER S320 Inverter features rich fault code prompts, helping users quickly locate and resolve issues. For example, when the inverter encounters an E004 acceleration overcurrent fault, possible causes include too fast acceleration, low grid voltage, or insufficient inverter power. To address such faults, methods such as increasing the acceleration time, checking the input power supply, or selecting an inverter with a larger power rating can be employed.

Similarly, when the inverter experiences an E026 water shortage fault, possible causes include municipal water pipe network shortage, pump failure, or sensor failure. To address such faults, one can check whether parameters E0.19, E0.20, E0.21, and E0.22 are set correctly or seek help from professional service personnel.

IV. Conclusion

The WELLER S320 Inverter, as a powerful and flexible variable frequency speed control device, plays an important role in various industrial control systems. By reasonably selecting sensor types and ranges, calibrating pressure, setting pressure deviation-related parameters, and configuring the PID sleep and wake-up functions, the inverter can accurately reflect the system status and operate stably. Additionally, through external start mode and return water control settings, as well as relay output function configurations, the inverter can realize联动 control with other devices and meet the needs of different systems. Furthermore, familiarity with the meaning and solutions of the inverter’s fault codes is also essential for ensuring the stable operation of the system.

In practical applications, users should perform personalized settings and adjustments to the inverter based on specific requirements and regularly maintain and inspect the inverter to ensure its long-term stable operation. Simultaneously, when encountering problems, users should promptly seek help from professional service personnel to ensure timely and effective solutions.