Introduction

The ENC EDH2200 series high-voltage inverter is commonly used in industrial applications for motor control. However, during operation, it may enter a “free stop (emergency stop)” state due to faults, rendering it unable to restart. Based on an actual case, this article analyzes the causes of the inverter’s “free stop” fault, focusing on the impact of the input terminal S1# function configuration (P05.00), and summarizes solutions and preventive measures.

Fault Background

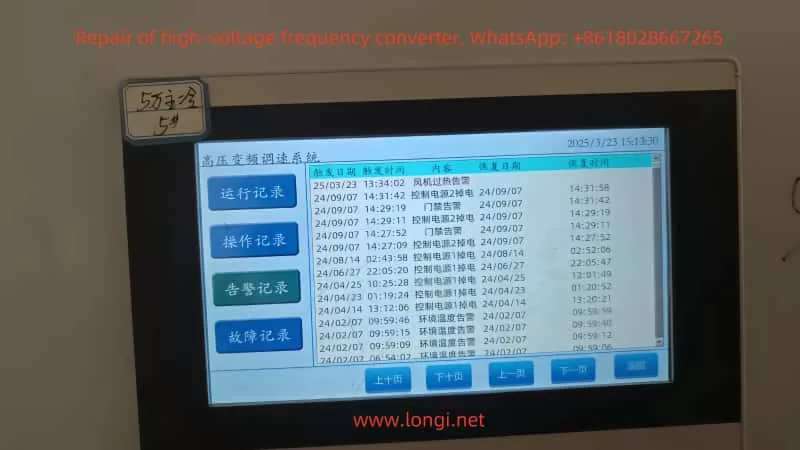

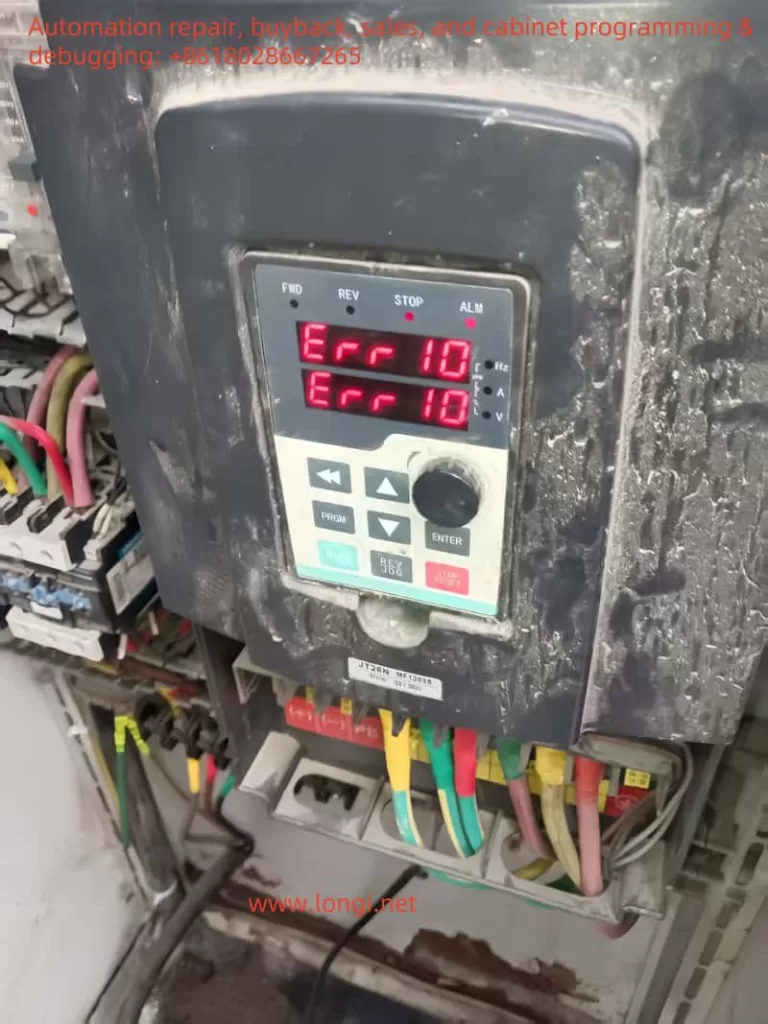

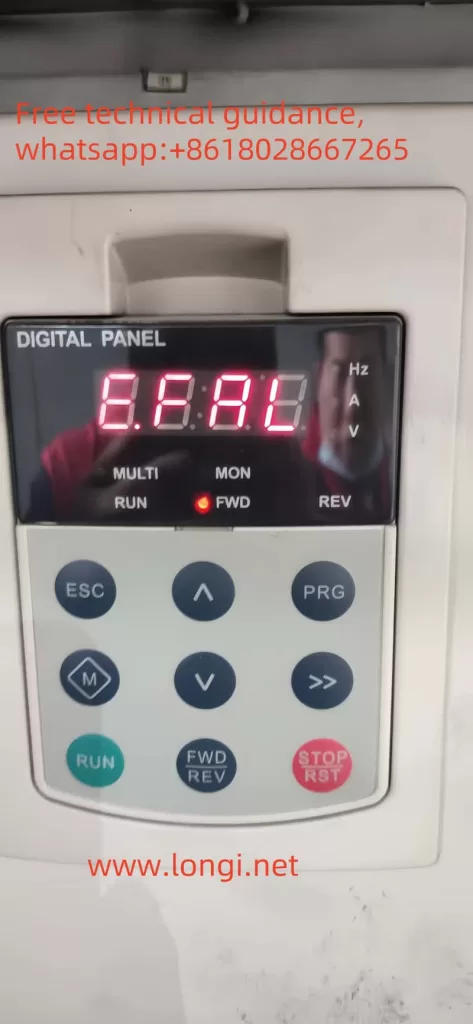

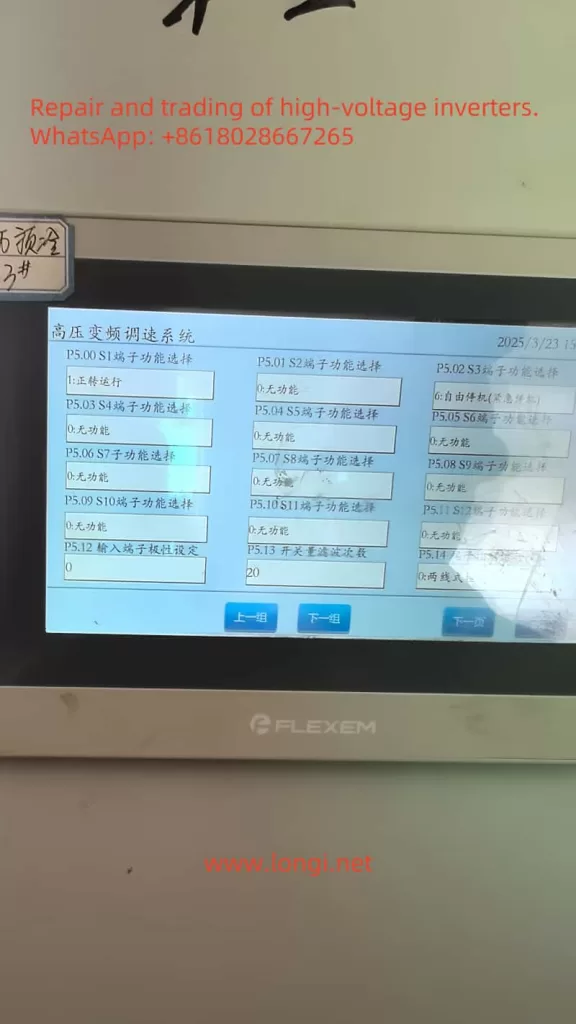

The inverter control panel (Attachment 5.jpg) displays an “actual alarm POFF state,” with operational parameters at 0 (input/output voltage 0V, current 0A, frequency 0Hz), indicating the system is in a non-operational state. The operation log (Attachment 1.jpg) shows S3# as “self-generated accident (total accident),” initially considered the root cause. However, after adjusting the S1# terminal function (P05.00) from “1: Lift given” to “0: No function,” the system returned to normal, and the inverter successfully restarted.

Fault Cause Analysis

Based on the operation log and the actual resolution process, the following is a detailed analysis of the fault causes:

- Impact of S1# Function Configuration

- P05.00 (S1# function selection) was originally set to “1: Lift given,” likely used to receive signals from external devices (e.g., pump lift control signals).

- If the external device fails to provide a correct signal (e.g., signal loss, abnormality, or interference), the system may misjudge it as a fault and trigger a protection mechanism, leading to “free stop.”

- Changing P05.00 to “0: No function” removes S1# from control, and the system exits the protection state, indicating that the S1# configuration is the core issue.

- Correlation with S3# “Self-Generated Accident”

- S3# (P05.02) displays “self-generated accident (total accident),” which may be a chain reaction triggered by S1# malfunction.

- The inverter’s protection logic may be designed to trigger a total accident (S3#) and enter emergency stop mode when an abnormality is detected on a terminal (e.g., S1#).

- Possible External Factors

- S1# may be connected to external devices (e.g., pumps or sensors). If the device malfunctions or there are wiring issues (e.g., loose connections, short circuits), it may cause signal abnormalities.

- Environmental interference (e.g., electromagnetic interference) may also affect S1# signal transmission.

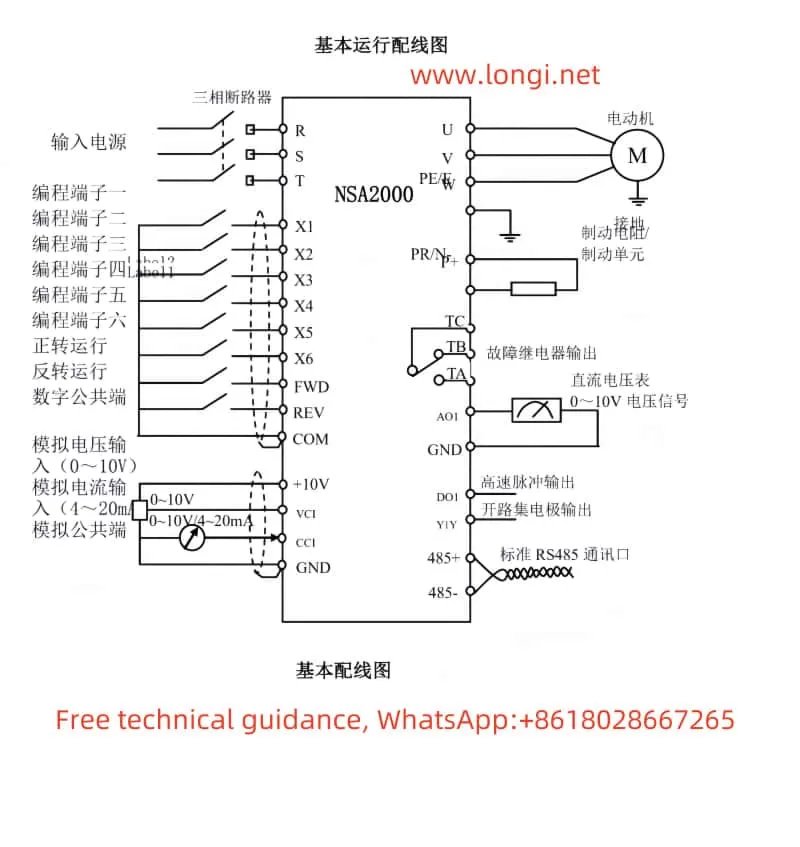

- Hardware and Parameter Configuration

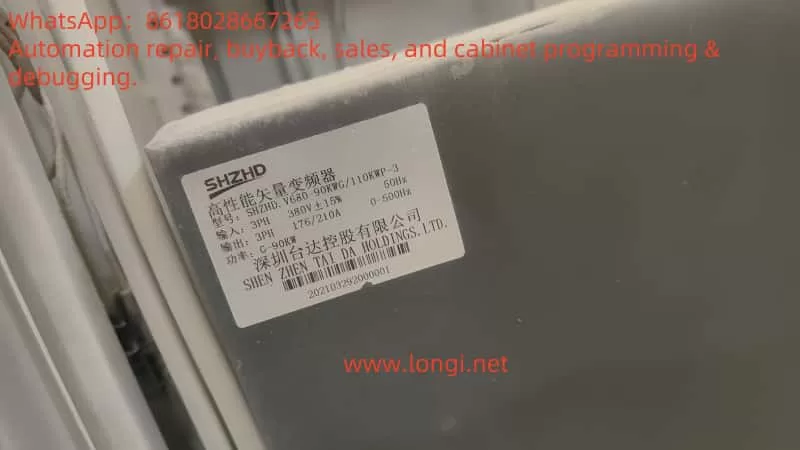

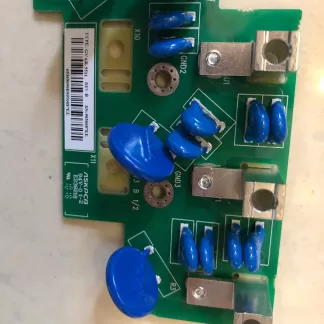

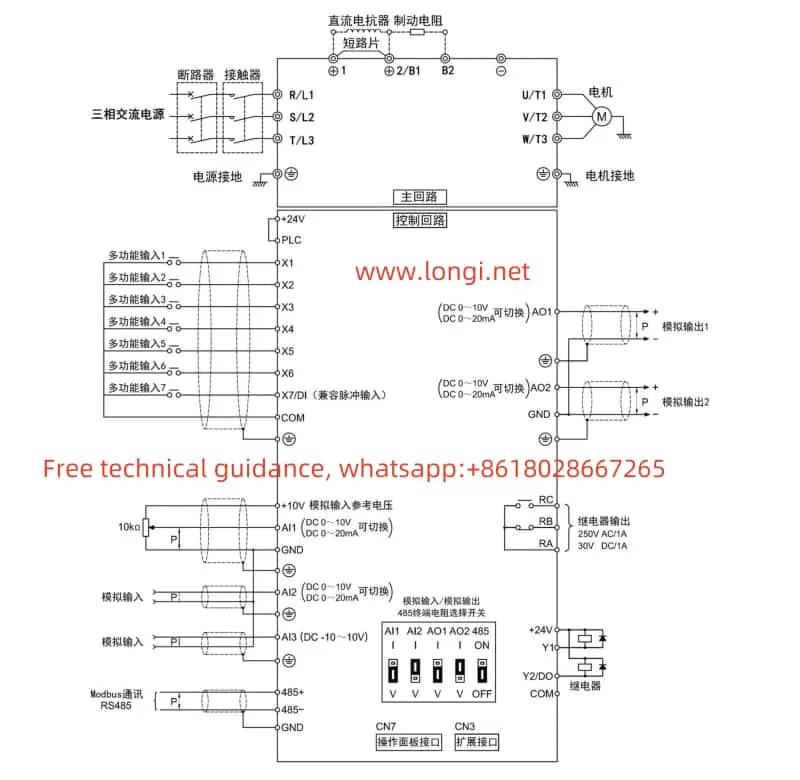

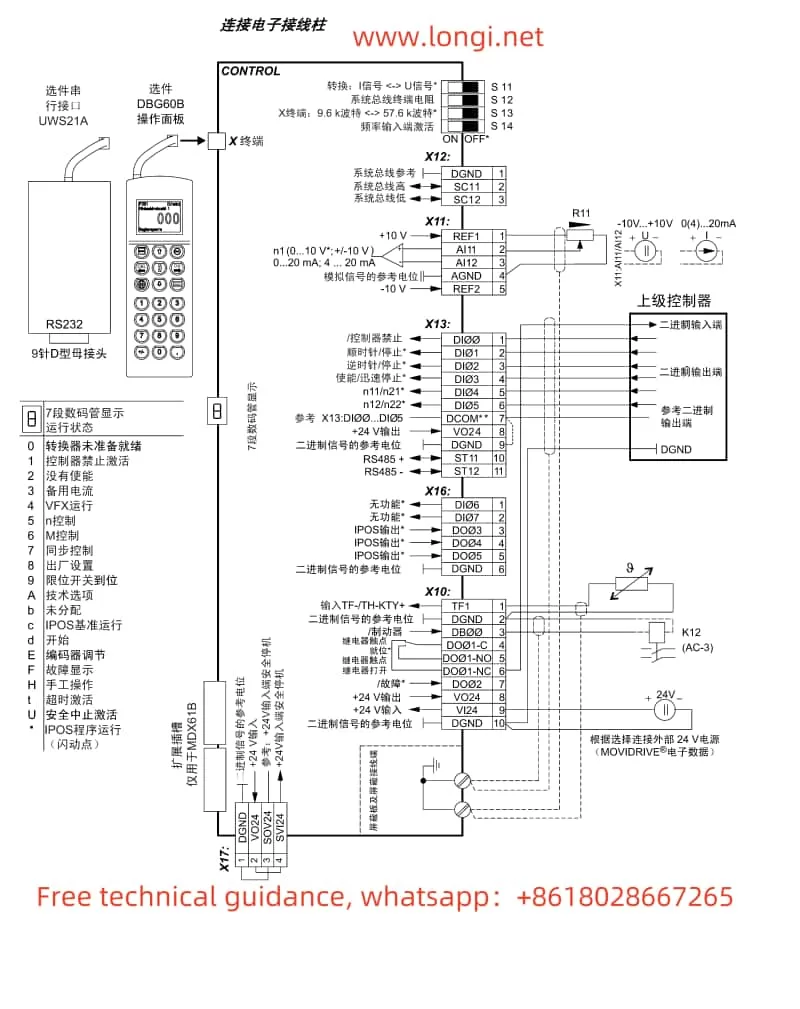

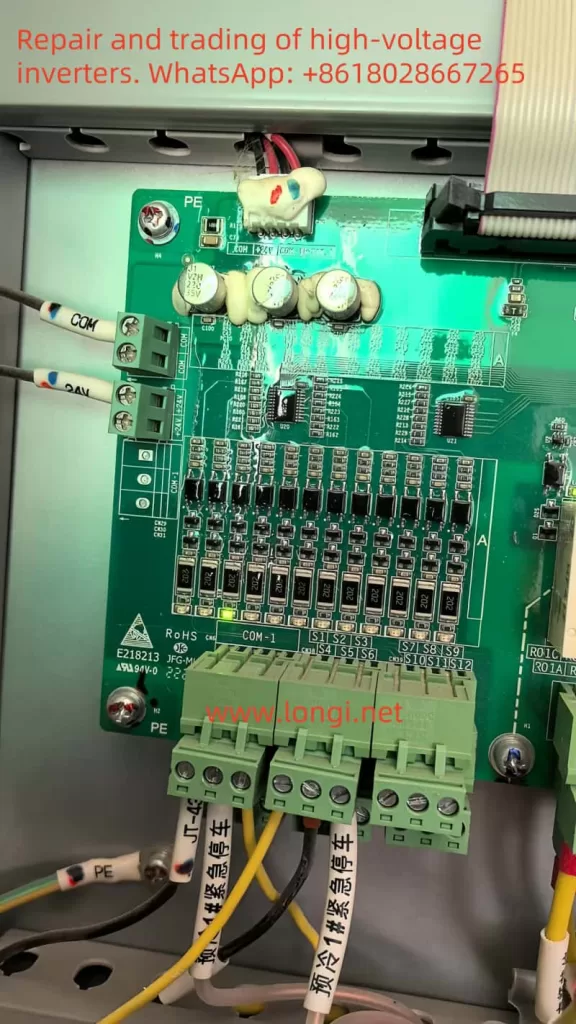

- Circuit board images (Attachments 3.jpg and 4.jpg) show relays K4/K5 and terminal connections. If S1#-related hardware is damaged, it may cause signal errors.

- Improper configuration of P05 group parameters (input terminal function selection) may lead to system misjudgment.

Resolution Process

- Problem Identification

- The control panel displays “POFF state,” and the operation log shows S3# as “self-generated accident.” However, the “lift given” function of S1# raises concerns.

- Referencing the P05 group parameter table (Attachment 6.jpg), it is confirmed that S1# (P05.00) is set to “1: Lift given.”

- Parameter Adjustment

- Change P05.00 from “1” to “0” (no function) to remove S1# from control.

- After adjustment, use the control panel’s “reset” function to clear the alarm.

- System Recovery

- Press the “start” button, and the inverter successfully restarts with operational parameters returning to normal (voltage, current, frequency, etc., no longer 0).

Summary of Solutions

- Core Solution Steps: Change P05.00 (S1# function) from “1: Lift given” to “0: No function,” remove S1#’s control function, clear the alarm, and restart the system.

- Preventive Measures:

- Check S1#’s wiring and external devices to ensure normal signal transmission.

- Regularly maintain hardware to prevent loose connections or component damage.

- Record parameter adjustments for future troubleshooting.

Unexpected Findings

- The S3# “self-generated accident” record may only be a result, not the cause. The actual issue stems from the S1# configuration. This highlights the need to consider all relevant terminals and parameters when troubleshooting inverter faults, rather than focusing solely on alarm records.

- The control panel brand is FLEXEM, while the inverter is ENC, which may involve terminological or logical differences. For example, the “POFF” state is defined in FLEXEM but not explicitly mentioned in the ENC manual.

Table: Fault Causes and Solutions

| Fault Phenomenon | Possible Cause | Solution |

|---|---|---|

| Free stop, unable to start | S1# function (lift given) mis-trigger | Change P05.00 to “0: No function” |

| S3# displays self-generated accident | Chain reaction from S1# abnormal signal | Clear alarm after resolving S1# issue |

| System displays POFF state | Protection mechanism triggers power-off | Restart system after clearing alarm |

| External device signal abnormality | Loose wiring or device fault | Check S1# wiring and external devices |

Conclusion

The “free stop (emergency stop)” issue in the ENC EDH2200 high-voltage inverter is caused by improper configuration of the S1# terminal function (P05.00), potentially triggered by abnormal external signals. By changing the S1# function to “no function,” the system returns to normal. Users are advised to regularly check terminal wiring and external devices, optimize parameter configurations, and take preventive measures to avoid recurrence of similar issues.